Kelp seasoning production line and production method

A production line and kelp technology, applied in chemical instruments and methods, mixers, dissolving, etc., can solve the problems of reducing the quality of kelp seasoning and reducing the efficacy of kelp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

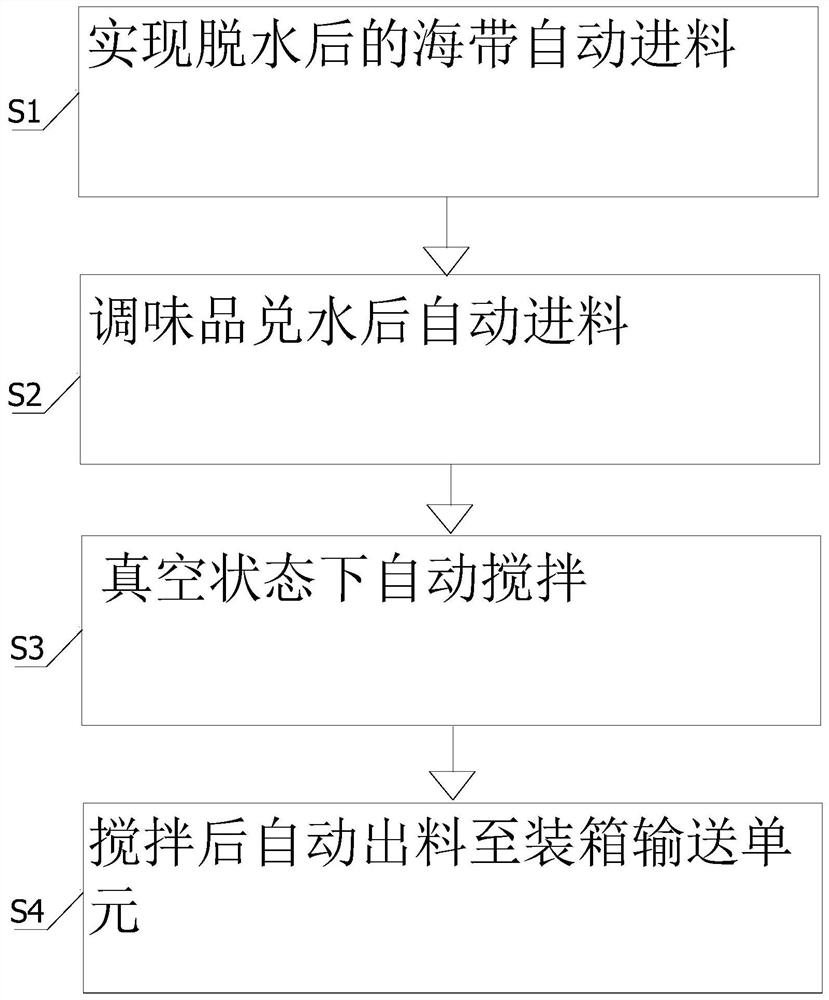

[0049] In order to solve the technical problem of how to season kelp in a real environment, such as figure 2 , Image 6 with Figure 9 As shown, the following preferred technical solutions are provided:

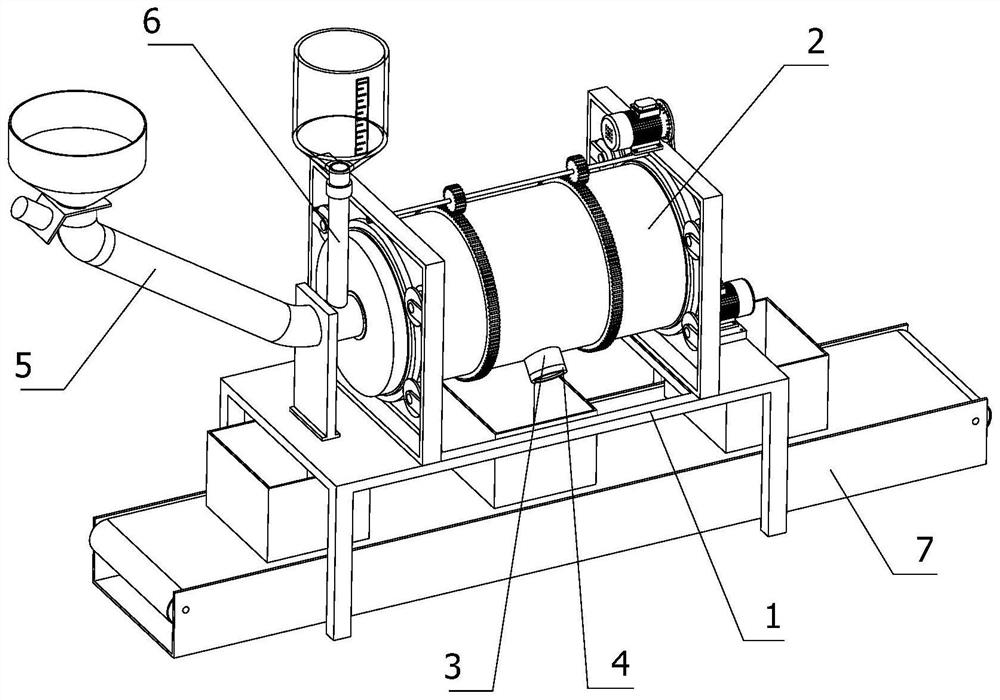

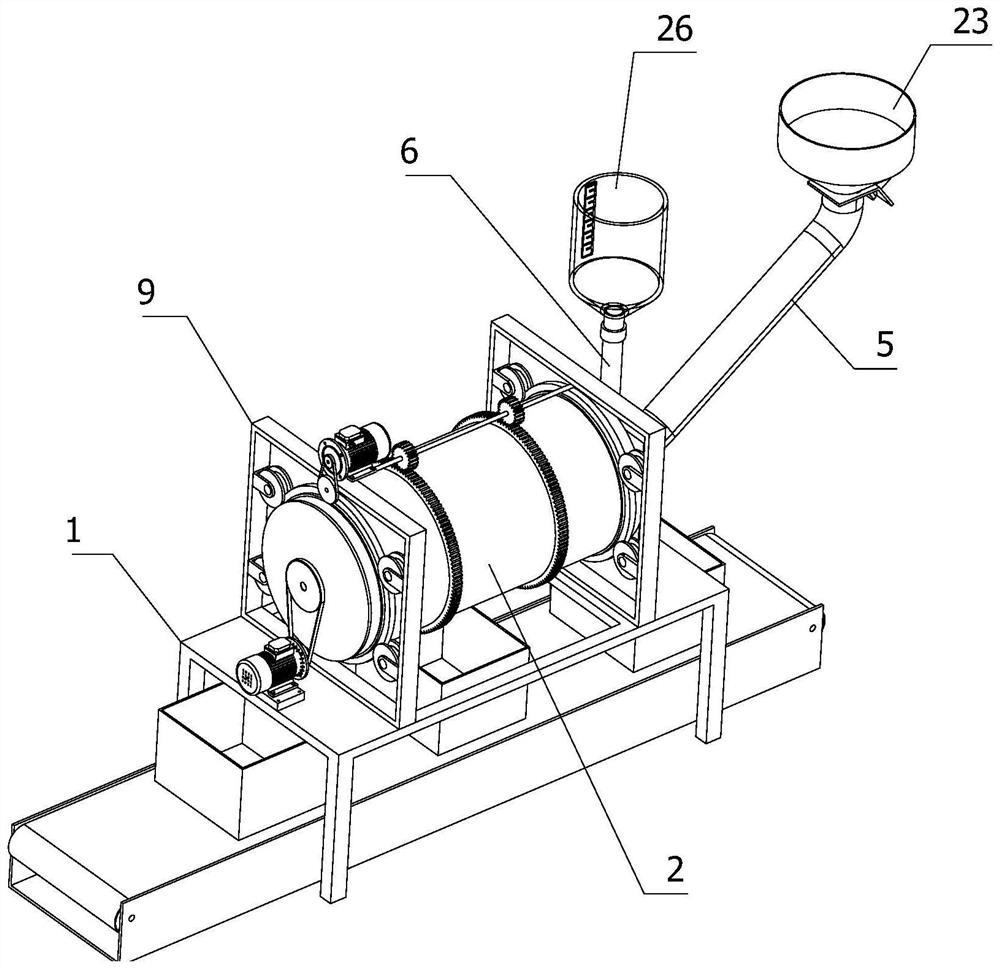

[0050] A kelp seasoning production line, comprising a frame 1, a mixing drum 2, a kelp feeding pipe 5, a condiment feeding pipe 6 and a packing conveying unit 7, the mixing drum 2 is horizontally arranged above the frame 1, and the stirring The middle end position of cylinder 2 is provided with a material outlet 3, and electromagnetic valve 4 is arranged on the material outlet 3, and the kelp feed pipe 5 is positioned at an end of the mixing drum 2 in an inclined shape, and the output of the kelp feed p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com