Low-viscosity and high-thermal-conductivity two-component potting silica gel

A high thermal conductivity, low viscosity technology, applied in the direction of heat exchange materials, adhesives, polymer adhesive additives, etc., can solve the problems of viscosity increase, limit the thermal conductivity of potting silica gel, etc., to prolong the service life and ensure work Stability and reliability, homogeneous mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

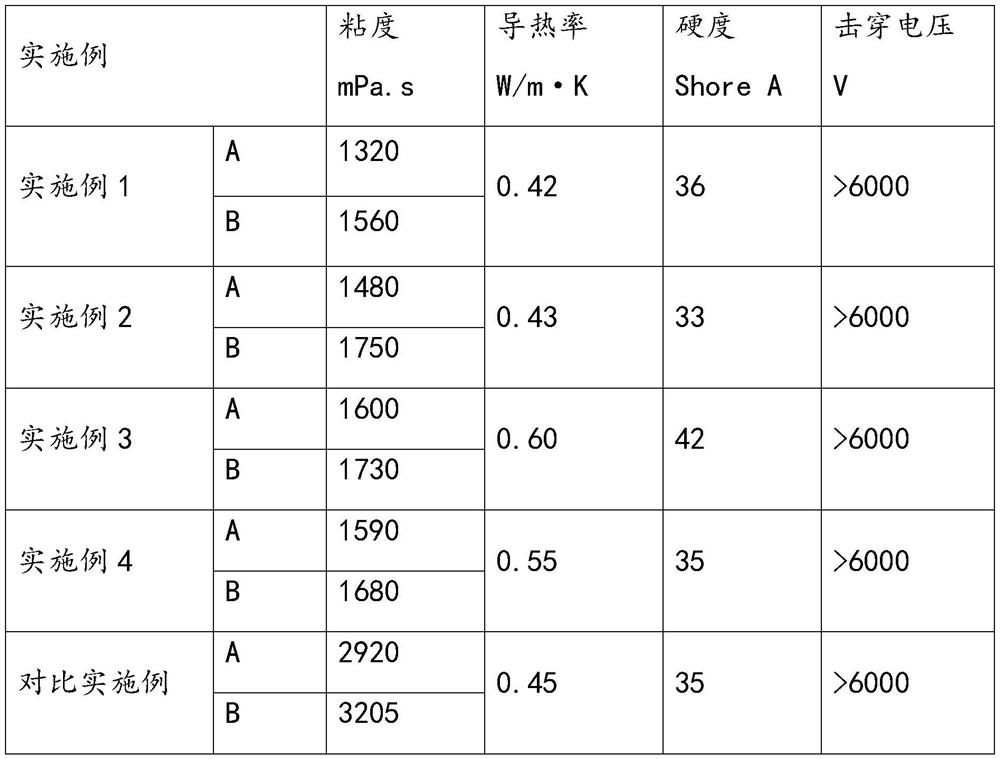

Examples

Embodiment 1

[0032] Weigh 10 parts of vinyl silicone oil with a viscosity of 3000mPa.s, 10 parts of vinyl silicone oil with a viscosity of 200mPa.s, 1 part of hydrogen-containing silicone oil, 15 parts of aluminum hydroxide with an average particle size of 5 μm, and spherical alumina powder with an average particle size of 40 μm 25 parts of carbon black and 0.5 parts of carbon black were sequentially added into a double planetary power mixing mixer, and mechanically stirred for 2 hours under the conditions of vacuum degree -0.1MPa, rotation speed of 400 rpm, and revolution speed of 8 rpm to obtain a composite Point A, packaged and placed for use.

[0033] Weigh 10 parts of vinyl silicone oil with a viscosity of 3000mPa.s, 10 parts of vinyl silicone oil with a viscosity of 200mPa.s, 0.1 part of platinum catalyst with a concentration of 5000ppm, and 15 parts of aluminum hydroxide with an average particle size of 5μm and an average particle size of 40μm 25 parts of spherical alumina powder an...

Embodiment 2

[0038] Weigh 50 parts of vinyl silicone oil with a viscosity of 2000mPa.s, 10 parts of hydrogen-containing silicone oil, 30 parts of aluminum hydroxide with an average particle size of 5 μm, and 10 parts of spherical alumina powder with an average particle size of 0.1 μm and a spherical shape with an average particle size of 5 μm 20 parts of alumina powder, 30 parts of spherical alumina powder with an average particle size of 30 μm, and 5 parts of iron red are added to the double planetary power mixer in turn, and the vacuum degree is -0.1MPa, and the rotation speed is 400 rpm. Under the condition of a speed of 8 revolutions / min, mechanical stirring was performed for 2 hours to obtain component A, which was packaged and placed for use.

[0039] Weigh 55 parts of vinyl silicone oil with a viscosity of 2000mPa.s, 1 part of platinum catalyst with a concentration of 5000ppm, 30 parts of aluminum hydroxide with an average particle size of 5 μm, 10 parts of spherical alumina powder w...

Embodiment 3

[0045] Weigh 35 parts of vinyl silicone oil with a viscosity of 1000mPa.s, 5 parts of hydrogen-containing silicone oil, 25 parts of spherical aluminum nitride powder with an average particle size of 5 μm, 40 parts of spherical alumina powder with an average particle size of 50 μm, and 3 parts of iron red , put into the double planetary power mixing mixer in turn, under the conditions of vacuum degree -0.1MPa, rotation speed of 400 rpm, and revolution speed of 8 rpm, mechanically stir for 2 hours to obtain component A, pack and store for use.

[0046] Weigh 38 parts of vinyl silicone oil with a viscosity of 1000mPa.s, 0.5 parts of platinum catalyst with a concentration of 5000ppm, 25 parts of spherical aluminum nitride powder with an average particle size of 5 μm, 40 parts of spherical alumina powder with an average particle size of 50 μm, carbon Add 3 parts of black into the double planetary power mixing mixer in turn, then add into the double planetary power mixing mixer in tu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com