Rock plate and preparation method thereof

A technology of slabs and cuboids, which is applied in the field of ceramics, can solve the problems of consumers' aesthetic fatigue, poor surface flatness, and poor stain resistance of products, and achieve the effect of high-quality feeling, thick feeling, and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] One embodiment of the present invention provides a method for preparing rock slabs, comprising the following steps:

[0044] S101: preparing a green body.

[0045] It can be understood that existing methods can be used to prepare green bodies, preferably step S101 includes the following steps:

[0046] S1011: Obtain powder;

[0047] In some embodiments, the moisture content of the powder in step S1011 is 6.5%-7.0%. In some embodiments, the moisture content of the green body is controlled at 6.5%, 6.6%, 6.7%, 6.8%, 6.9% or 7%, so as to facilitate the formation of a dense green body, facilitate the subsequent steps, and improve the quality of the green body. The strength of the body meets the strength requirements of rock slabs.

[0048] In some embodiments, by mass percentage, the chemical composition of the powder includes: SiO 2 60%-64%, Al 2 o 3 22%-26%, TiO 2 +Fe 2 o 3 0.2%-0.6%, MgO 1%-2%, CaO 0.5%-1.2%, K 2 O 1.5%-2.5%, Na 2 O 2.5%-3.5%; further, the c...

Embodiment 1

[0107] Raw materials for preparing dry beads: 38 parts of potassium feldspar, 8 parts of albite, 8 parts of kaolin, 14 parts of barium carbonate, 6 parts of wollastonite, 4 parts of zinc oxide, 6 parts of strontium carbonate, 11 parts of calcite, quartz 2 parts, 3 parts of alumina;

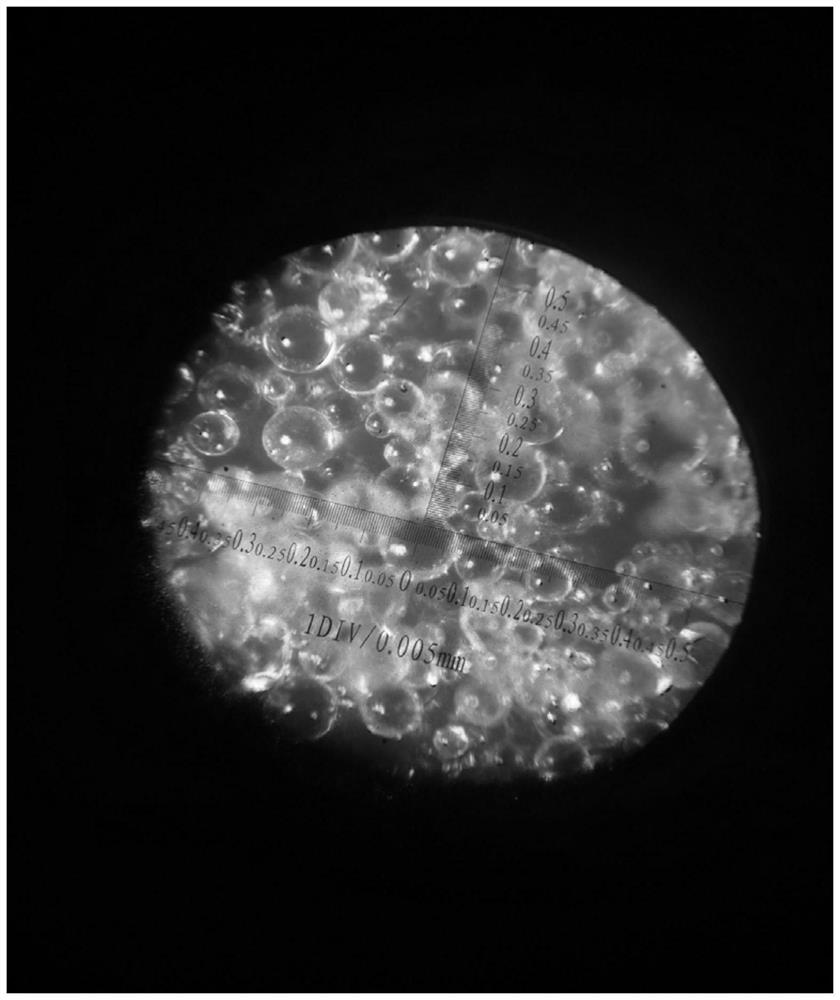

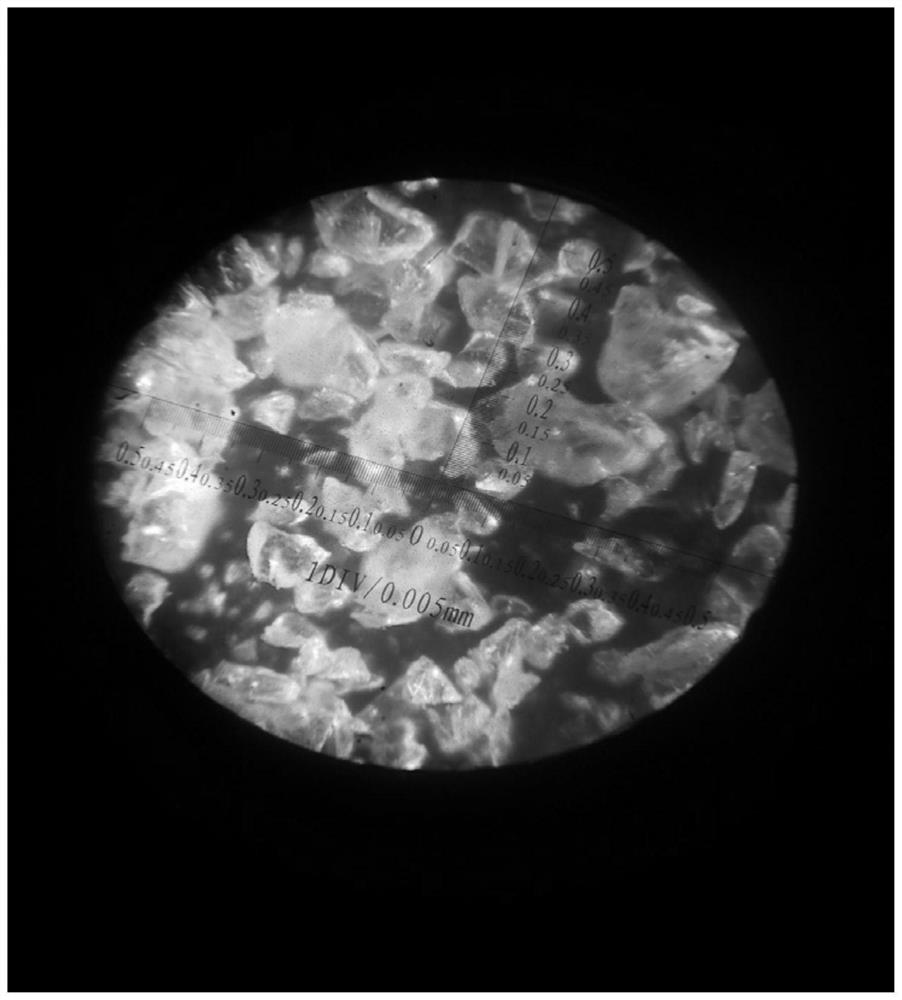

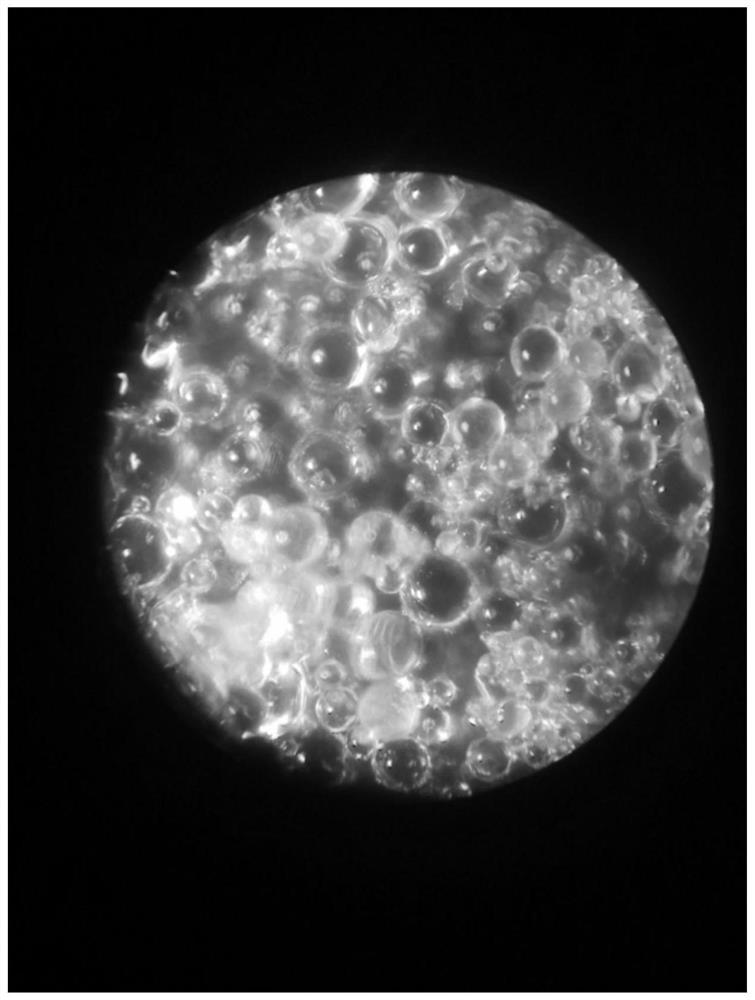

[0108] (1) Preparation of dry ball beads: Precisely mix the above raw materials and mix them evenly, then put the mixture into a frit furnace for firing, the temperature curve is: heating to 300°C for 10 minutes, and then heating for 30 minutes to 1100°C, then heated to 1450°C for 20 minutes, and then kept at 1450°C for 10 minutes. The above-mentioned materials are melted under this temperature curve, and then flow into the cold water tank through the discharge port for quenching to obtain the semi-finished product of dry ball bead, crush the semi-finished product of dry bead, and control the particle gradation between 250 mesh and 300 mesh ;Spray the dry beads obtained after crushing into the ve...

Embodiment 2

[0118] Raw materials for preparing dry beads: 30 parts of potassium feldspar, 10 parts of albite, 10 parts of kaolin, 13 parts of barium carbonate, 7 parts of wollastonite, 5 parts of zinc oxide, 7 parts of strontium carbonate, 12 parts of calcite, quartz 3 parts, 3 parts of alumina;

[0119] The preparation method is the same as in Example 1, and the difference is that the glaze and water-based glaze are different in (5) and (6), specifically:

[0120] Peel-off glaze: including 40% of peel-off base glaze, 45% of ethyl acetate flux, and 15% of additives. The peel-off base glaze is prepared from the following raw materials: 7 parts of calcined kaolin, 26 parts of potassium feldspar, sodium feldspar 18 parts of limestone, 8 parts of wollastonite, 4 parts of barium carbonate, 5 parts of zinc oxide and 33 parts of frit; by mass percentage, the chemical composition of frit includes: SiO 2 55.5%, Al 2 o 3 19%, CaO 4.5%, MgO 2.8%, K 2 O 4.6%, Na 2 O 4.7%, BaO 2% and ZnO 2.8%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com