Flexible general assembly workshop process line structure based on AGV

A line structure, assembly workshop technology, applied in the direction of motor vehicles, lifting devices, transportation and packaging, etc., can solve the problems of long construction period, high civil construction cost and large occupied space of the overall process line, so as to reduce civil construction cost and module The effect of high degree of automation and reduced construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

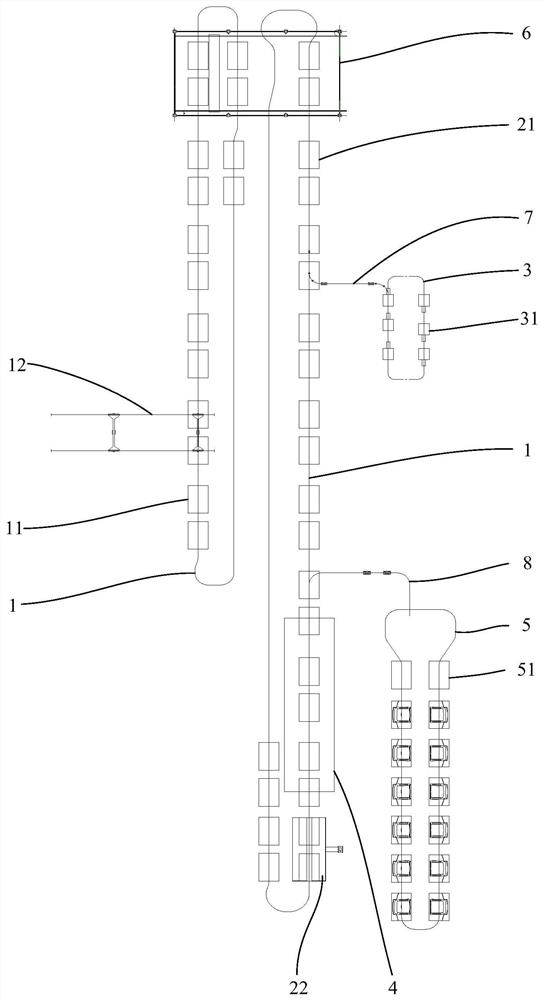

[0029] In related technologies, the assembly of automobiles often needs to go through multiple processes such as chassis assembly, engine assembly, cab assembly, tire assembly, and windshield assembly. Between multiple assembly production lines, conveyors or conveyor lines such as drag chains, skateboards, and plate chains are usually used to transport the car bodies to be assembled.

[0030] The vehicle body to be assembled is transported by the above-mentioned drag chain, skateboard, board chain and other conveyors or conveyor lines. After the process line is planned in the workshop, it is also necessary to carry out basic equipment such as supporting, guiding, and traction drives. construction, resulting in high civil engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com