Intelligent metallurgical coke prediction method combined with coke oven heating schedule parameters

A heating system and metallurgical coke technology, which is applied in the field of intelligent metallurgical coke prediction combined with coke oven heating system parameters, can solve the problems of lack of universality, large model differences, neglect of large-scale industrial production, etc. The effect of improving accuracy, good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to illustrate the application of the invention in coal blending optimization more clearly, the use state after the model is constructed is taken as an example to further illustrate. An intelligent metallurgical coke prediction method combined with coke oven heating system parameters, comprising the following steps:

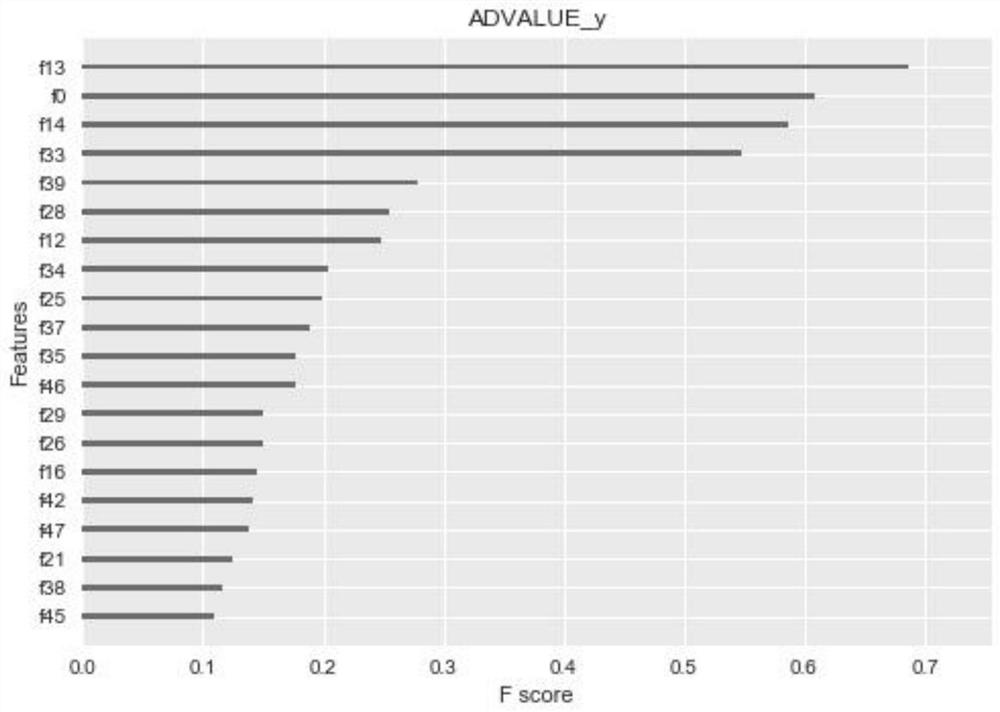

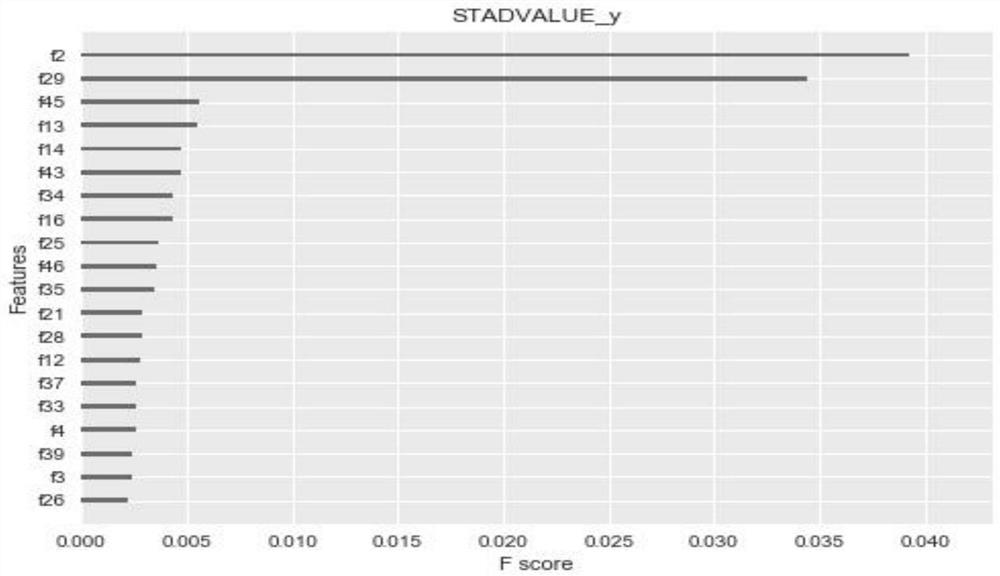

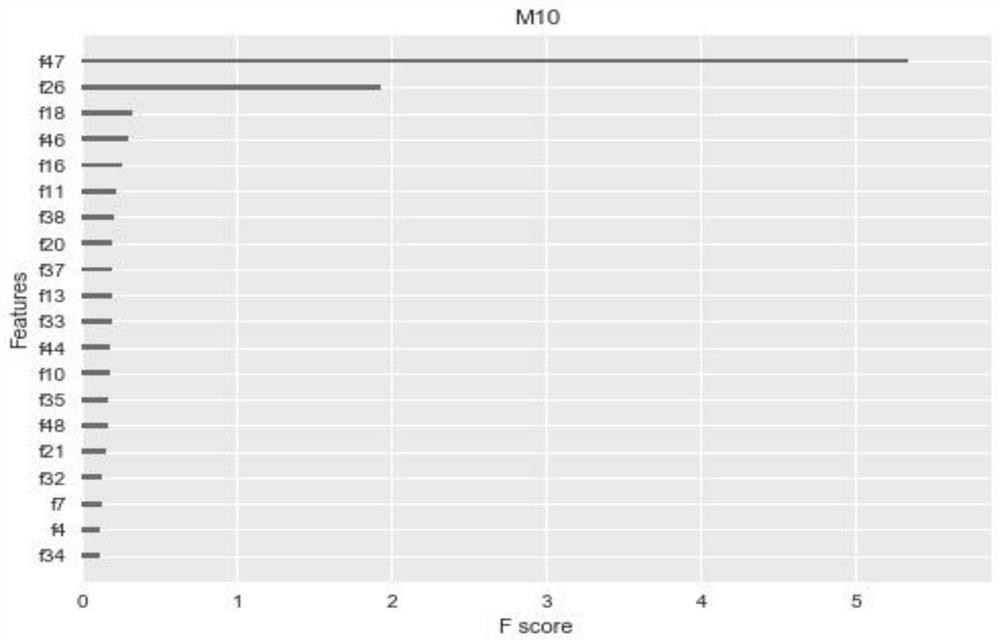

[0027] Determine the various indicators of the predicted coke (ash content, sulfur content, M10, M40, CRI, CSR). After parameter optimization, a model whose accuracy meets the requirements is obtained, and then the model itself is analyzed, the relative variable importance is calculated, and the correlation evaluation between each characteristic variable and the target variable is obtained by statistical summary.

[0028] The input and output of the specific model are shown in Table 1 and Table 2:

[0029] Table 1 Correlation analysis model input

[0030]

[0031]

[0032]

[0033] Table 2 Correlation analysis model output

[0034] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com