Water surface trash cleaning ship for environment management

A technology for environmental management and cleaning ships, which is used in the cleaning of open water surfaces, special-purpose ships, and general water supply conservation. , the effect of improving salvage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

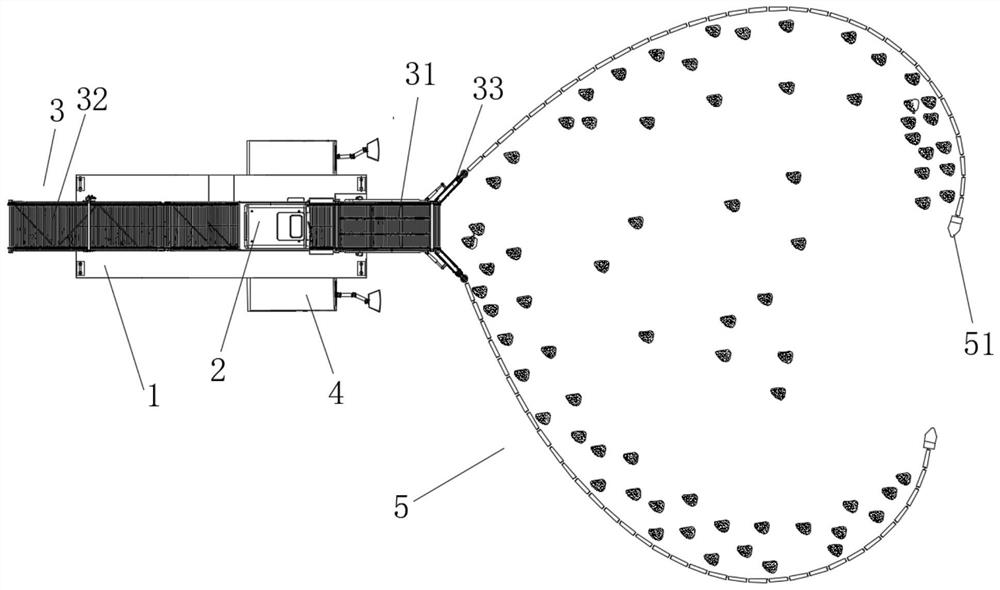

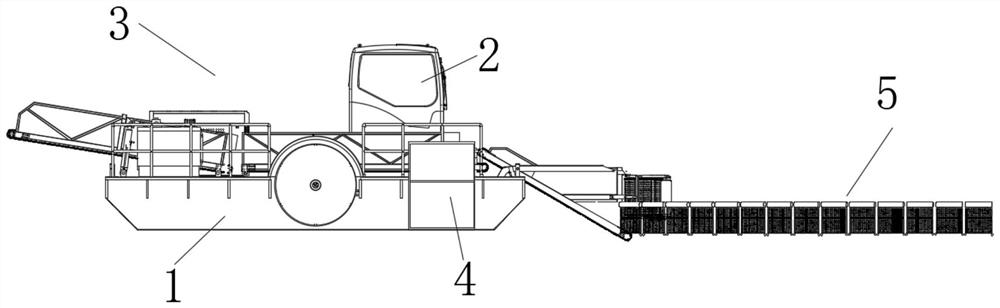

[0039] Specific embodiment one: as figure 1 , figure 2 As shown, when the water surface needs to clean up solid garbage and the main hull 1 cannot enter the water area, the staff can remotely control the tug boat 51 to a designated position in the cockpit 2, surround the water surface garbage, and then remotely control the tug boat 51 to the main boat. The movement of the hull in the direction 1 drives water surface garbage to gather in the direction of the main hull 1. The collection compartment 31 provided on the main hull 1 collects garbage, and the chain conveyor belt provided on the collection compartment 31 transports the garbage to the storage compartment 32 for storage.

specific Embodiment 2

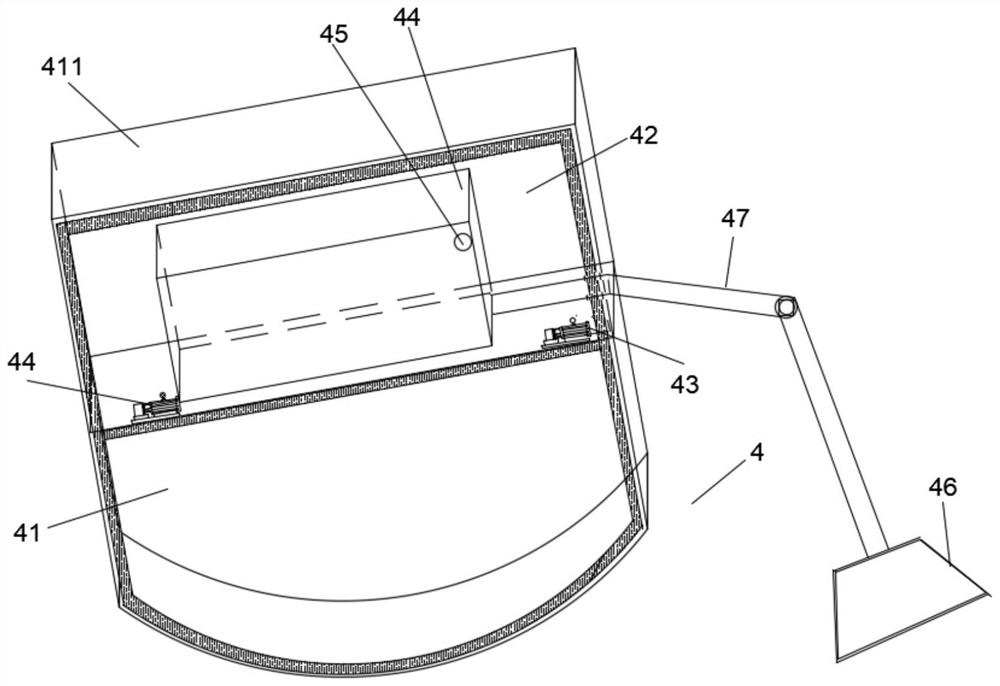

[0040] Specific embodiment two: as figure 1 , image 3 As shown, when it is necessary to collect oil slicks on the water surface and the main hull 1 cannot enter the water area, the staff can remotely control the tug boat 51 to a designated position in the cockpit 2, surround the oil slick on the water surface, and then remotely control the tug boat 51 to the designated position. The main hull moves in direction 1, driving the oil slick on the water surface to gather in the direction of main hull 1. At this time, the mechanical arm 47 controls the oil collecting suction head 46 to insert into the oil slick on the water surface, and the first oil suction pump 43 starts to work. After filtering through the filter screen, the water Pumped into the vacuum separation box 42 together with the slick oil, the vacuum separation box 42 is in a negative pressure state at this time, the water in the vacuum separation box 42 together with the slick oil floating on it will rise to a certain...

specific Embodiment 3

[0041] Specific embodiment three: as Figure 4 , Figure 5 as well as Figure 6 As shown, when the power detection system 515 on the tug boat 51 detects the minimum power, the signal is sent to the automatic navigation control system 514, and the automatic navigation control system 514 performs calculation and sends a control command to control the tug boat 51 to return to the charging dock. 63. When the towing boat 51 approaches the charging dock 63, the object sensing device 637 on the front door panel 636 senses the towing boat 51, and sends the signal to the micro-controller 638, and the micro-controller 638 controls the hydraulic cylinder to extend, and the front door panel 636 Open, and electrify the first electromagnet 6341, then insert the second electromagnet 517 at the position of the charging port of the towing boat 51 into the groove, and stick to the first electromagnet 6341, at this time, the charging port 635 of the towing boat and the charging board 635 docki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com