Magnesium alloy material for building formwork and preparation method

A technology of building templates and magnesium alloys, which is applied in the field preparation of building components, construction, building construction, etc., can solve the problems of slow extrusion processing speed, unstable mechanical properties of building templates, and high production costs, and achieve the reduction of flux slag, improve corrosion resistance, improve the effect of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

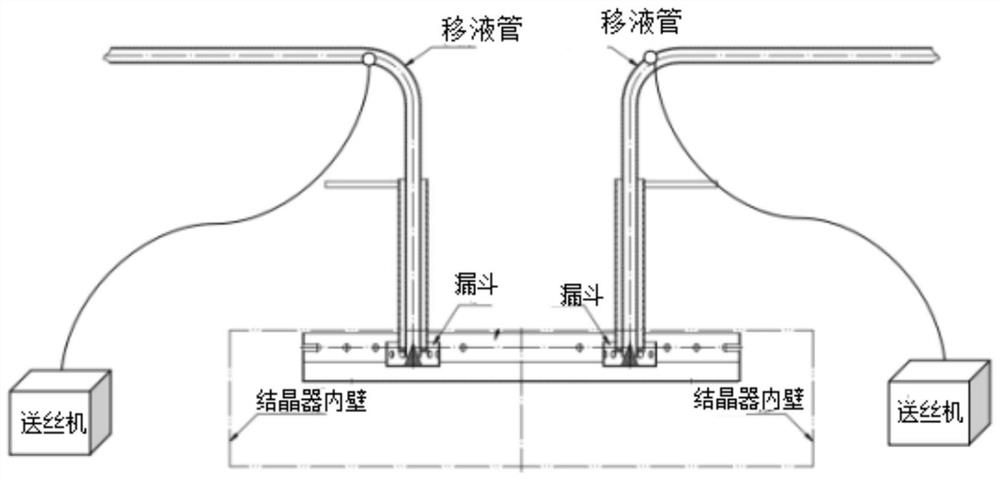

[0030] refer to figure 1 , a magnesium alloy material for building templates, comprising the following raw materials in mass fractions: 0.25% Ca, 0.25% Y, 0.35% Sn, 0.1% Sr, and the rest is AZ41.

[0031] This embodiment also proposes a preparation method of magnesium alloy material for building formwork, comprising the following steps:

[0032] S1. Melting: heating and melting the magnesium alloy in a clean crucible to obtain magnesium liquid;

[0033] S2. Alloying: Add aluminum ingots and zinc ingot alloying elements, heat up to 730°C, and at the same time sprinkle anhydrous manganese chloride evenly on the liquid surface, wait for anhydrous manganese chloride to form a hard shell, then use a mixer or argon gas Stir to melt it all;

[0034] S3. Refining: For the first refining, use a mixer or argon gas to sprinkle refining agent while stirring, and sprinkle 75% of the prepared refining agent;

[0035] S4, slag removal and second refining: use the preheated slag spoon to s...

Embodiment 2

[0046] refer to figure 1 , a magnesium alloy material for building templates, comprising the following raw materials in mass fractions: 0.5% Ca, 0.4% Y, 0.6% Sn, 0.3% Sr, and the rest is AZ41.

[0047] This embodiment also proposes a preparation method of magnesium alloy material for building formwork, comprising the following steps:

[0048] S1. Melting: heating and melting the magnesium alloy in a clean crucible to obtain magnesium liquid;

[0049] S2. Alloying: Add aluminum ingots and zinc ingot alloying elements, heat up to 735°C, and at the same time sprinkle anhydrous manganese chloride evenly on the liquid surface, wait for anhydrous manganese chloride to form a hard shell, then use a mixer or argon gas Stir to melt it all;

[0050] S3. Refining: For the first refining, use a mixer or argon gas to sprinkle refining agent while stirring, and sprinkle 75% of the prepared refining agent;

[0051] S4, slag removal and second refining: use the preheated slag spoon to star...

Embodiment 3

[0062] refer to figure 1 , a magnesium alloy material for building templates, comprising the following raw materials in mass fractions: 0.6% Ca, 0.5% Y, 0.8% Sn, 0.5% Sr, and the rest is AZ41.

[0063] This embodiment also proposes a preparation method of magnesium alloy material for building formwork, comprising the following steps:

[0064] S1. Melting: heating and melting the magnesium alloy in a clean crucible to obtain magnesium liquid;

[0065] S2. Alloying: Add aluminum ingots and zinc ingot alloying elements, heat up to 740°C, and at the same time sprinkle anhydrous manganese chloride evenly on the liquid surface, wait for anhydrous manganese chloride to form a hard shell, then use a mixer or argon gas Stir to melt it all;

[0066] S3. Refining: For the first refining, use a mixer or argon gas to sprinkle refining agent while stirring, and sprinkle 75% of the prepared refining agent;

[0067] S4, slag removal and second refining: use the preheated slag spoon to star...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com