Method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud

A terephthalic acid, high-purity technology, used in chemical instruments and methods, carboxylate preparation, organic compound preparation, etc., can solve the problems of inability to remove, secondary pollution, and low product purity, and achieve economical and effective recovery. Use and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

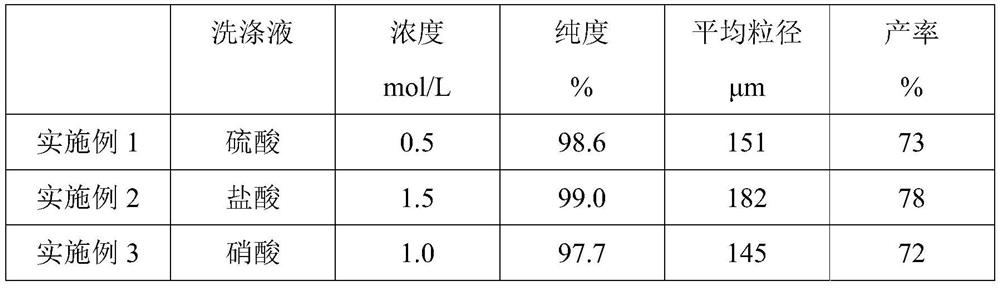

Embodiment 1

[0028] A method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud, comprising:

[0029] Take 10 g of printing and dyeing white mud, wash it with 30 mL of sulfuric acid solution with a concentration of 0.5 mol / L (containing 0.05 mol / L fatty alcohol polyoxyethylene ether), and centrifuge to obtain white mud filter cake; disperse the white mud filter cake in 50 mL of pure In water, use sodium hydroxide to adjust the pH to 7.0, place it in a hydrothermal kettle with a capacity of 80mL for hydrothermal reaction (150°C, 12h), and obtain the hydrothermal reaction product; centrifuge the hydrothermal product, and use an appropriate amount of pure water to dissolve The filter cake is dispersed and washed, centrifuged again to take the solid and dried to obtain a terephthalic acid product.

Embodiment 2

[0031] A method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud, comprising:

[0032] Take 10 g of printing and dyeing white mud, use 30 mL of hydrochloric acid solution with a concentration of 1.5 mol / L to wash (containing 0.05 mol / L fatty alcohol polyoxyethylene ether), and centrifuge to obtain white mud filter cake; disperse the white mud filter cake in 50 mL of pure In water, use sodium hydroxide to adjust the pH to 7.0, place it in a hydrothermal kettle with a capacity of 80mL for hydrothermal reaction (150°C, 12h), and obtain the hydrothermal reaction product; centrifuge the hydrothermal product, and use an appropriate amount of pure water to dissolve The filter cake is dispersed and washed, centrifuged again to take the solid and dried to obtain a terephthalic acid product.

Embodiment 3

[0034] A method for hydrothermally recovering high-purity terephthalic acid from printing and dyeing white mud, comprising:

[0035] Take 10 g of printing and dyeing white mud, wash it with 30 mL of nitric acid solution with a concentration of 1.0 mol / L (containing 0.05 mol / L fatty alcohol polyoxyethylene ether), and centrifuge to obtain white mud filter cake; disperse the white mud filter cake in 50 mL of pure In water, use sodium hydroxide to adjust the pH to 7.0, place it in a hydrothermal kettle with a capacity of 80mL for hydrothermal reaction (150°C, 12h), and obtain the hydrothermal reaction product; centrifuge the hydrothermal product, and use an appropriate amount of pure water to dissolve The filter cake is dispersed and washed, centrifuged again to take the solid and dried to obtain a terephthalic acid product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com