High-precision lossless assembling equipment for double-row cylindrical roller bearing

A technology for cylindrical roller bearings and assembly equipment, which is applied in the field of bearing manufacturing and processing, can solve problems such as high working intensity and impact on bearing quality, and achieve the effects of reduced processing difficulty, convenient processing, and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

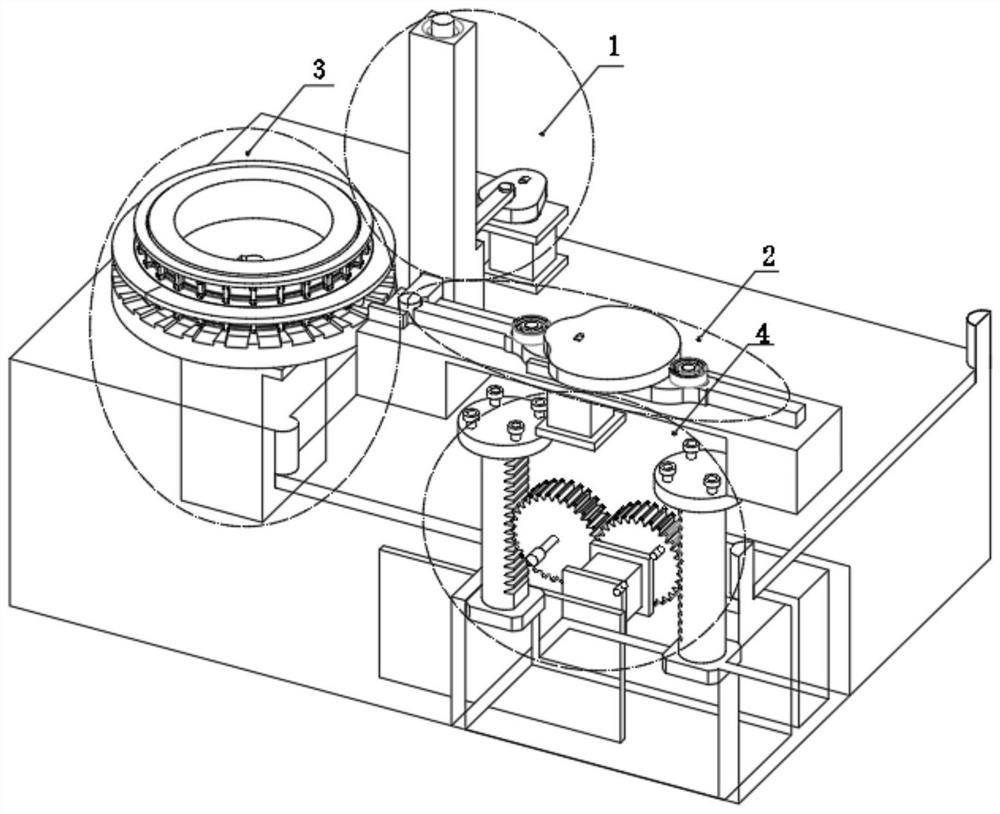

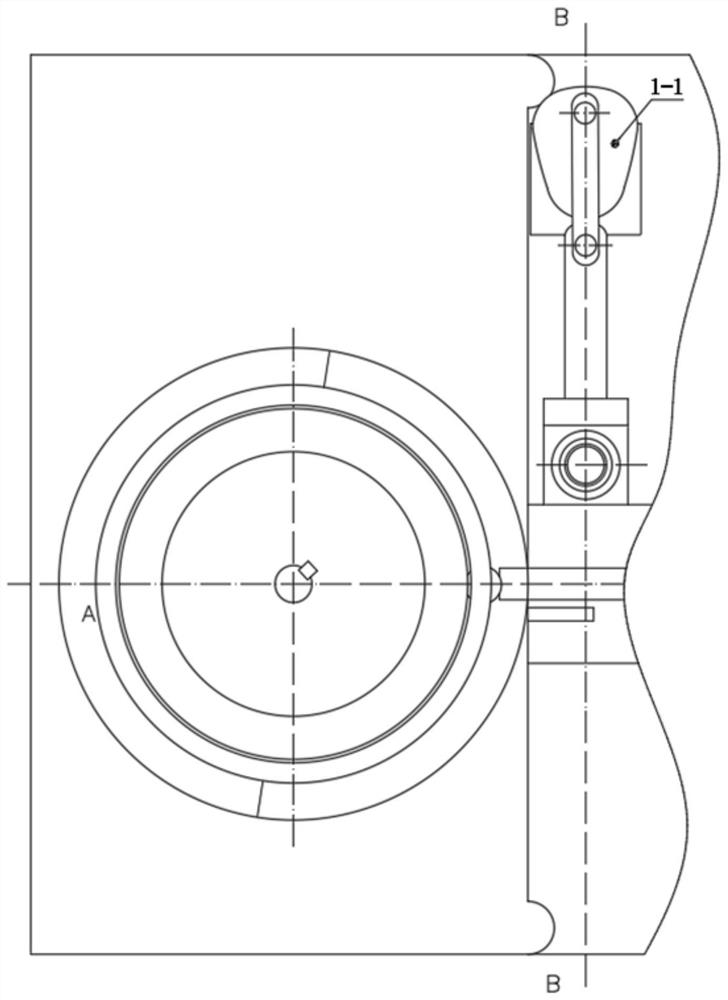

[0020] Specific implementation mode one: combine Figure 1 to Figure 7 Describe this embodiment, a high-precision double-row cylindrical roller bearing non-destructive assembly equipment described in this embodiment includes a feeding device 1, a cam pushing roller mechanism 2, a bearing rotation device 3 and a working platform lifting mechanism 4; Push in roller mechanism 2 and be installed on the working platform elevating mechanism 4, feeding device 1 is installed in the side of cam pushing in roller mechanism 2 left ends, and bearing equalization rotating device 3 is installed in the left end of cam pushing in roller mechanism 2.

specific Embodiment approach 2

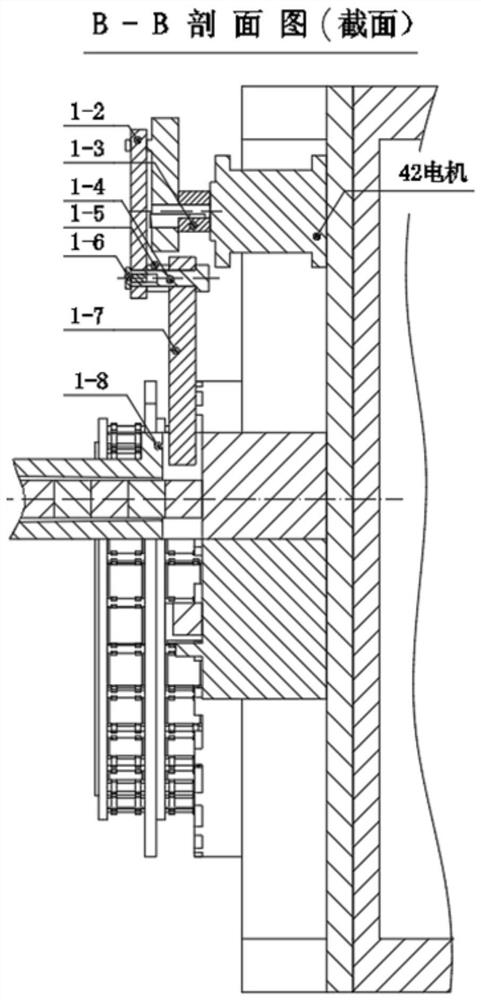

[0021] Specific implementation mode two: combination Figure 1 to Figure 7 Describe this embodiment. The feeding device 1 of a non-destructive assembly equipment for high-precision double row cylindrical roller bearings described in this embodiment includes a crank 1-1, a crank arm 1-2, a support bushing 1-3, and a connecting shaft 1- 4. Push rod 1-7, material channel 1-8 and motor 42; one end of crank 1-1 is connected with the motor shaft of motor 42, and support bushing 1-3 is fixedly set on the motor shaft of motor 42, and crank 1- The other end of 1 is connected with one end of the crank arm 1-2, the other end of the crank arm 1-2 is rotationally connected with the upper end of the push rod 1-7 through the connecting shaft 1-4, and the lower end of the push rod 1-7 pushes the material channel 1 Roller inside -8.

[0022] The push rod 1-7 promotes the roller fixed in the material channel 1-8 on the working platform, and pushes the roller to the specified position on the sl...

specific Embodiment approach 3

[0025] Specific implementation mode three: combination Figure 1 to Figure 7 To illustrate this embodiment, the feeding device 1 of a high-precision double-row cylindrical roller bearing non-destructive assembly equipment described in this embodiment also includes a small support sleeve 1-5 and a compression nut 1-6; a small support sleeve 1-5 set On the connecting shaft 1-4, and the small support sleeve 1-5 is located between the push rod 1-7 and the crank arm 1-2, and the compression nut 1-6 is sleeved on the outer end of the connecting shaft 1-4. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com