Secondary guide puncture needle device with bottle cap pressing function

A puncture needle and bottle cap pressing technology, which is applied in the field of experimental instruments, can solve problems such as damage, small puncture area, and cross-contamination, and achieve the effects of preventing deformation and bending, solving cross-contamination, and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

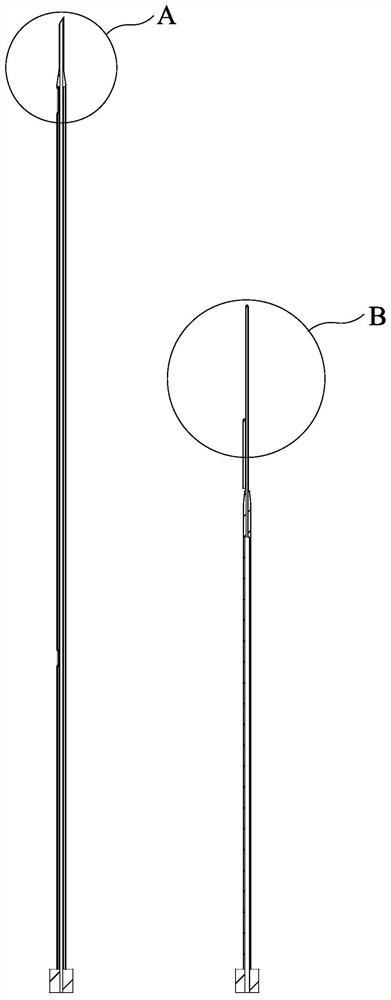

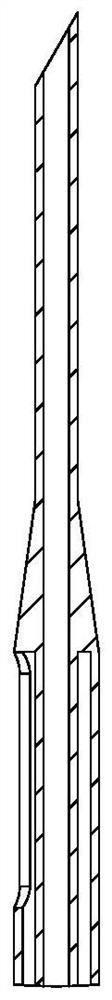

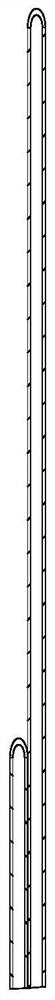

[0039] The invention provides a secondary guiding puncture needle device with the function of pressing the bottle cap, such as Image 6 and Figure 7 As shown, it includes a bracket 1, a puncture needle 2, a ventilation needle 3, a first drive mechanism 4, a second drive mechanism 5, a secondary guide mechanism 6, a first lead screw 7, a first slider 8, and a puncture needle seat 9 , the first guide sleeve 10, the second lead screw 11, the second slider 12, the ventilation needle seat 13, the gland mechanism 14, the guide rod 15, the limit block 16 and the PCB board (not shown in the figure). The PCB board is arranged on the back of the support 1, and the PCB board is connected to the first drive mechanism 4 and the second drive mechanism 5, and the secondary guide mechanism 6 includes a guide block 17, a guide shaft 18, a ball bushing 19, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com