Colorful card assembling equipment and application method thereof

A technology for assembling equipment and color cards, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of color card deformation, color card deformation and bending, and long time, so as to improve the success rate of assembly, avoid deformation and bending, The effect of short assembly times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

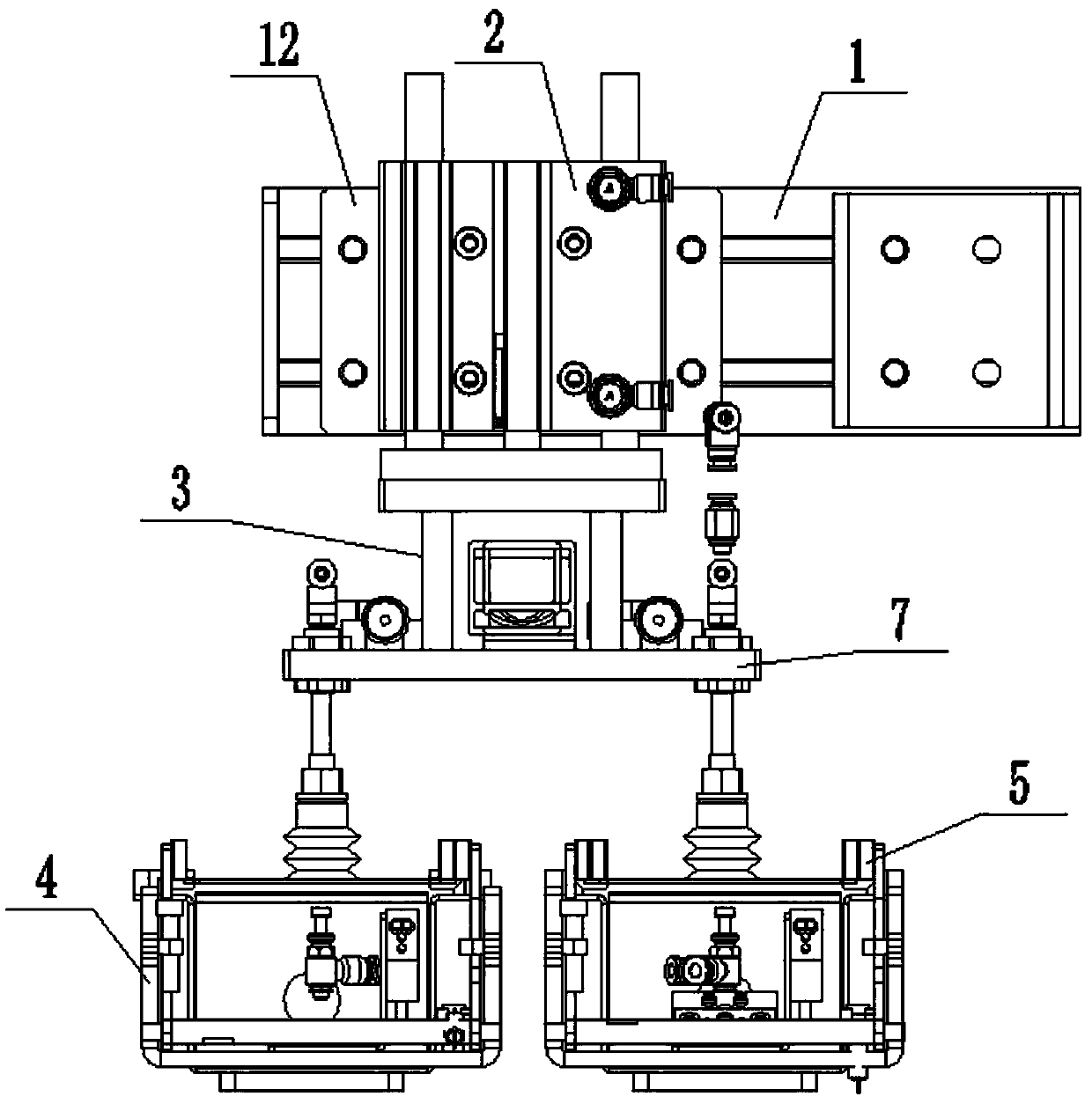

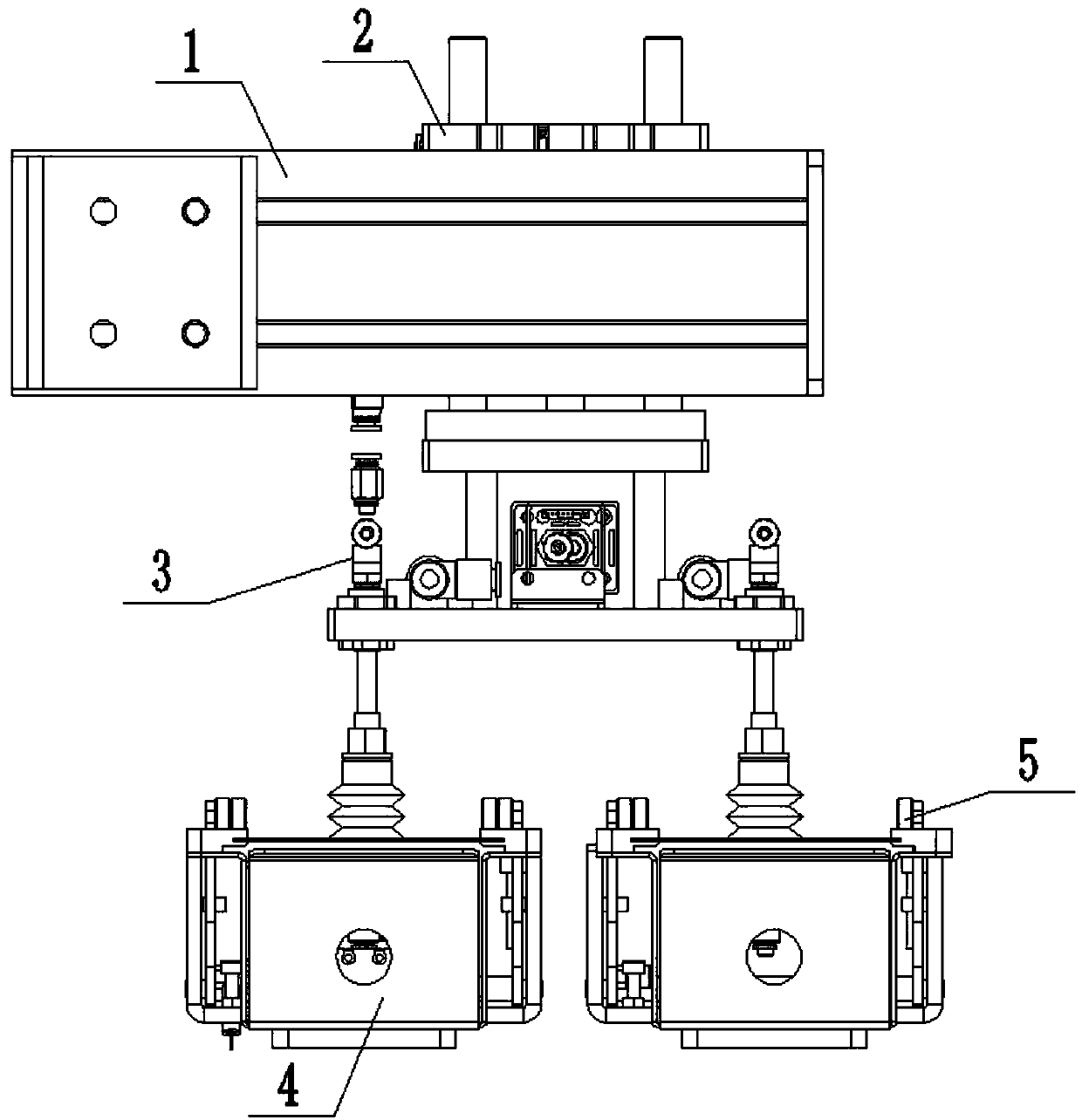

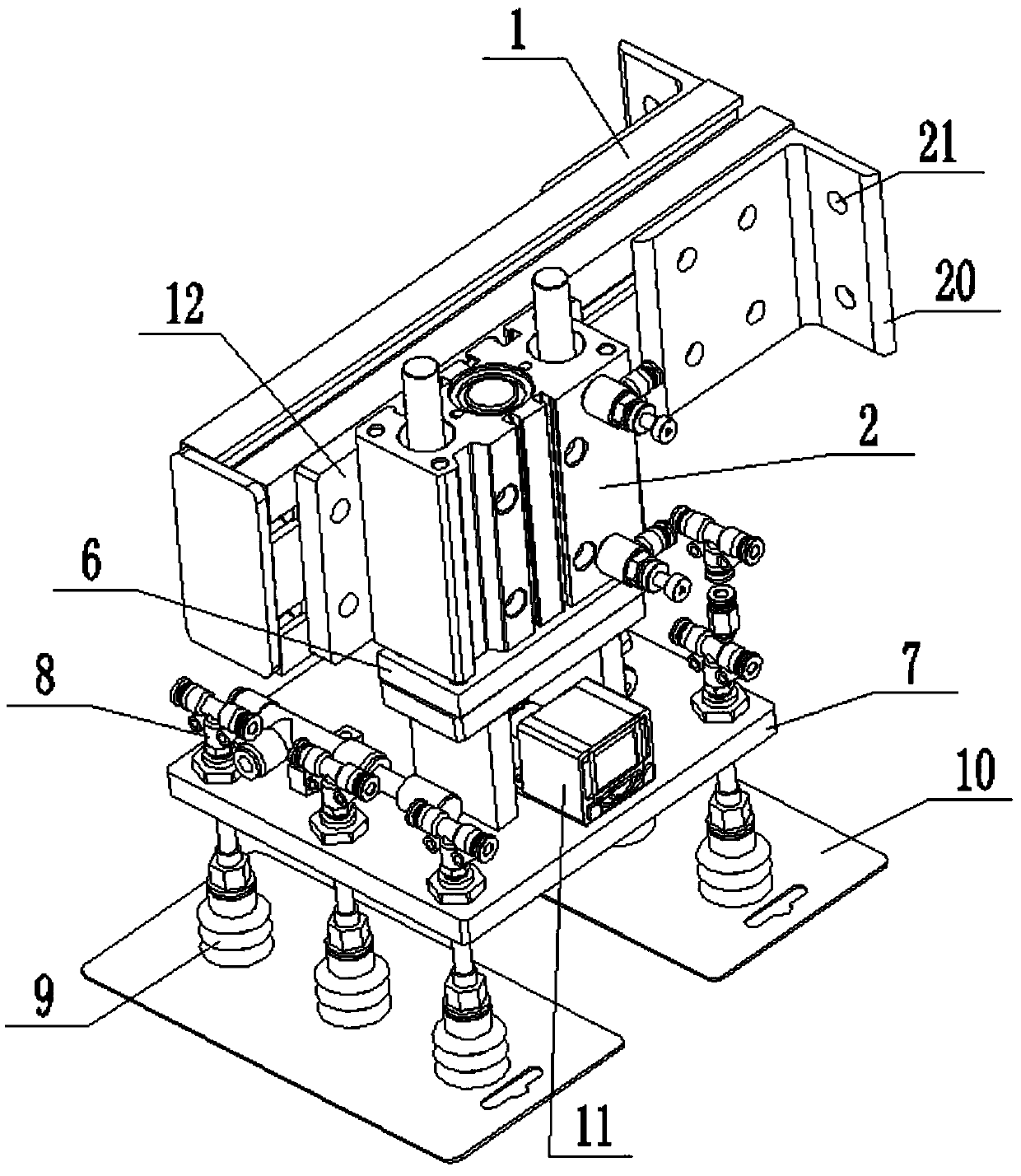

[0032] refer to Figure 1-11 , a kind of color card assembly equipment is proposed in this embodiment, including a cantilever 1, a cylinder 2 is slidably installed on one side of the cantilever 1, a color card clamp mechanism 3 is installed on the bottom of the cylinder 2, and a color card clamp mechanism 3 is provided directly in front. There are two blister cover positioning tooling 4, on which two blister cover positioning tooling 4 is inserted, a guide mechanism 5 is installed at the entrance of the blister cover positioning tooling 4, the color card fixture mechanism 3 includes a mounting plate 7, Two vacuum generators 8 are fixedly installed on the top of the mounting plate 7, and three vacuum suction cups 9 are fixedly connected to both sides of the bottom of the mounting plate 7, and one vacuum generator 8 in the two vacuum generators 8 is connected with six vacuum suction cups. Two of the vacuum chucks 9 in 9 are connected, and the other four vacuum chucks 9 of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com