FeOOH/Cu2O composite microsphere photocatalyst and preparation method thereof

A photocatalyst and composite microsphere technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. The effect of enriching, inhibiting recombination, and improving photocatalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

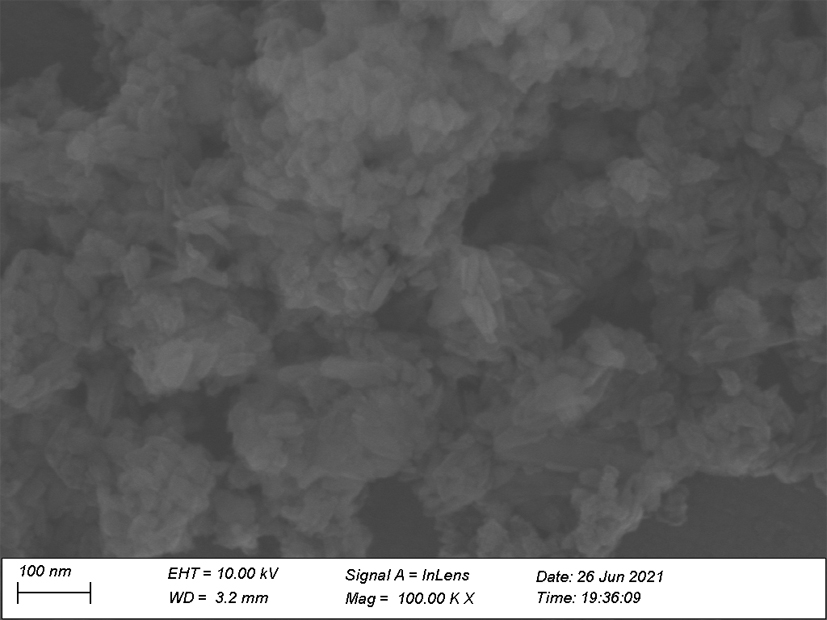

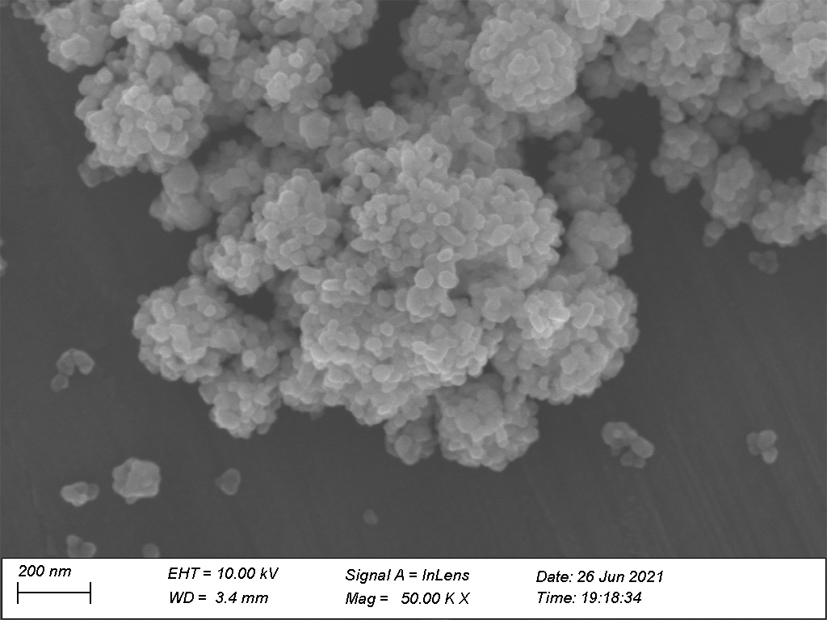

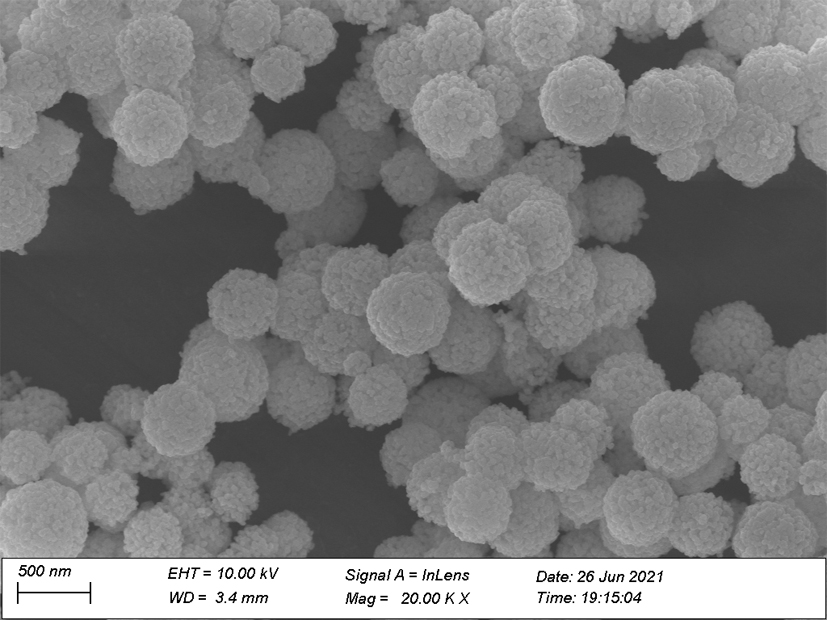

Image

Examples

Embodiment 1

[0034] FeOOH / Cu 2 The preparation method of O composite microsphere photocatalyst comprises the following steps:

[0035] S1. Preparation of FeOOH powder:

[0036] S1-1, 27.8 g ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) with 15.8 g ammonium bicarbonate (NH 4 HCO 3) mixed and ground for 10 minutes, after mixing and ground, 30 g of water was added to make a slurry, then the resulting slurry was stirred for 10 minutes and then filtered to obtain a filter cake;

[0037] S1-2. Add water with 0.5 times the weight of the filter cake to prepare a slurry, and pass ozone gas into the slurry for 10 minutes to carry out the oxidation reaction. At the same time, control the pH value of the slurry to maintain at 9.0, and then perform suction filtration on the slurry to obtain FeOOH, and the obtained FeOOH Drying is carried out to obtain FeOOH powder, and the FeOOH powder is ground for 10 minutes for later use, and the FeOOH is α-FeOOH;

[0038] S2, preparation of nano Cu 2 O dispe...

Embodiment 2

[0044] FeOOH / Cu 2 The preparation method of O composite microsphere photocatalyst comprises the following steps:

[0045] S1. Preparation of FeOOH powder:

[0046] S1-1, 40.0 g iron sulfate (Fe 2 (SO 4 ) 3 ) with 14.4 g ammonium carbonate ((NH 4 ) 2 CO 3 ) was mixed and ground for 60 minutes, after mixing and ground, 60 g of water was added to make a slurry, then the resulting slurry was stirred for 20 minutes and then filtered to obtain a filter cake;

[0047] S1-2. Add water twice the mass of the filter cake to prepare a slurry, and pass air into the slurry for 20 minutes to carry out the oxidation reaction. At the same time, the pH value of the slurry is kept at 10.0. When Fe in the slurry is detected 2+ Stop the reaction when / Fe is less than 4%, then suction filter the slurry to obtain FeOOH, dry the obtained FeOOH to obtain FeOOH powder, grind the FeOOH powder for 10min for later use, and the FeOOH is α-FeOOH;

[0048] S2, preparation of nano Cu 2 O dispersion: ...

Embodiment 3

[0052] FeOOH / Cu 2 The preparation method of O composite microsphere photocatalyst comprises the following steps:

[0053] S1. Preparation of FeOOH powder:

[0054] S1-1, 27.8 g ferrous sulfate heptahydrate (FeSO 4 ·7H 2 O) with 9.6 g ammonium carbonate ((NH 4 ) 2 CO 3 ) was mixed and ground for 40 minutes, after mixing and ground, 60 g of water was added to make a slurry, then the resulting slurry was stirred for 60 minutes and then filtered to obtain a filter cake;

[0055] S1-2. Add water 3 times the weight of the filter cake to prepare a slurry, and inject oxygen into the slurry for 15 minutes to react, while controlling the pH value of the slurry at 7.5, stop the reaction after injecting oxygen for 40 minutes, and then pump the slurry FeOOH was obtained by filtration, and the obtained FeOOH was dried to obtain FeOOH powder, and the FeOOH powder was ground for 10 minutes for later use, and the FeOOH was α-FeOOH;

[0056] S2, preparation of nano Cu 2 O dispersion:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com