Fermented feed raw material, preparation method of fermented feed raw material, fermented feed and preparation method thereof

A technology of fermenting feed and raw materials, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of mildew and indigestibility, and achieve the effect of easy digestion and absorption, easy digestion, and reduction of harmful gas concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

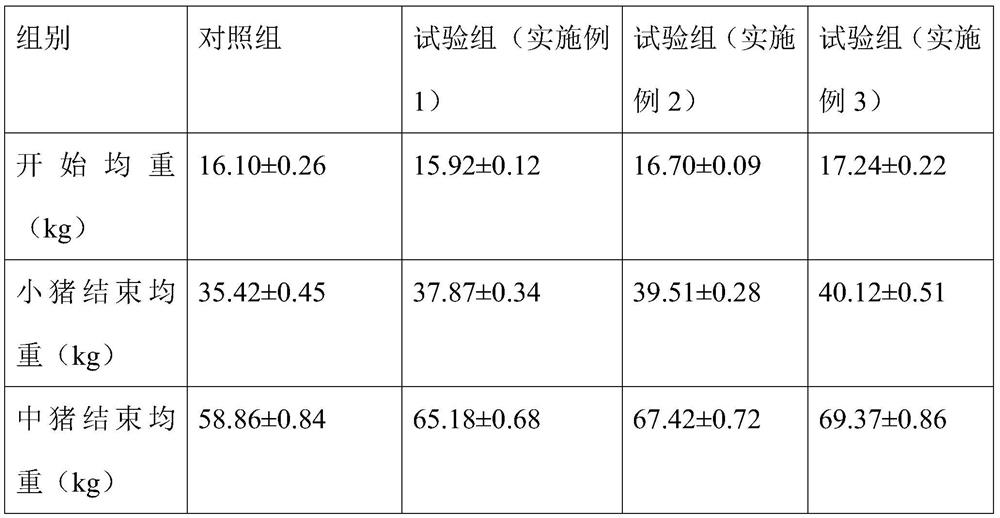

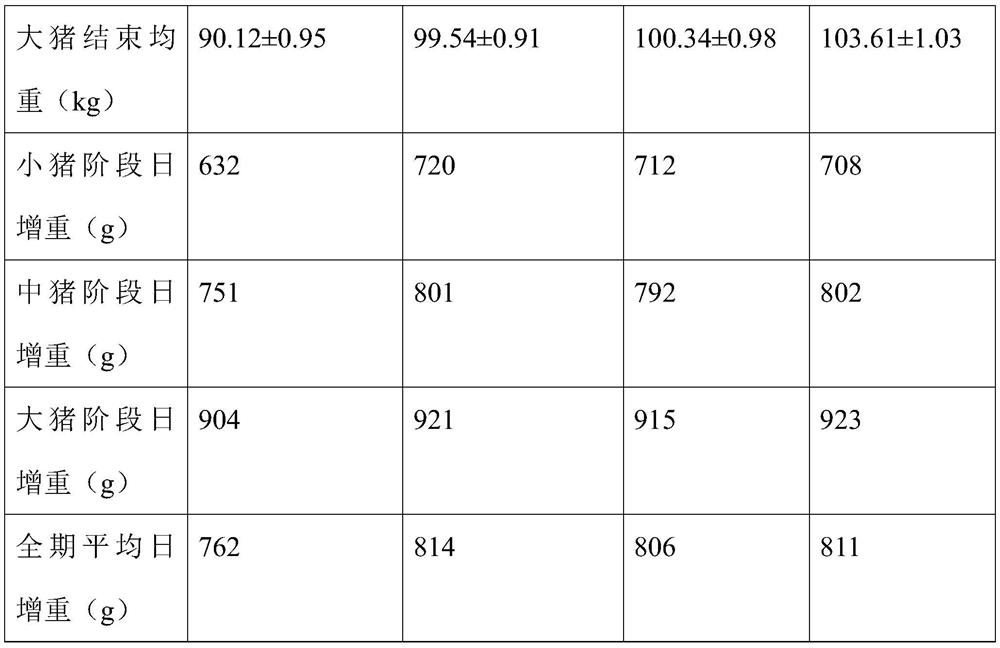

Examples

Embodiment 1

[0023] The preparation of fermented feed raw materials comprises the following steps:

[0024] S1. Weigh 250kg of corn, 100kg of soybean meal, 50kg of rapeseed meal, 50kg of sawdust, 10kg of soybean oil, 8kg of glucose, 0.5kg of starter and 310kg of water;

[0025] The starter is composed of 0.2kg of lactic acid bacteria, 0.2kg of Bacillus subtilis and 0.1kg of Candida prion;

[0026] S2. Mix corn, soybean meal, rapeseed meal, sawdust, soybean oil, glucose, starter and water evenly and ferment in piles;

[0027] S3. When the temperature rises to 35-40°C, turn the pile for heat dissipation and oxygen circulation for the first time, and cover it with plastic film to control temperature and oxygen;

[0028] S4. When the temperature rises to 35-40°C again, turn the pile for heat dissipation and oxygen circulation for the second time, and cover it with plastic film to control temperature and oxygen;

[0029] S5. When the temperature rises to 35-40°C again, turn the stack for the ...

Embodiment 2

[0036] The preparation of fermented feed raw materials comprises the following steps:

[0037] S1. Weigh 260kg of corn, 120kg of soybean meal, 80kg of rapeseed meal, 80kg of sawdust, 13kg of soybean oil, 10kg of glucose, 0.8kg of starter and 350kg of water;

[0038] The starter consists of 0.3kg of lactic acid bacteria, 0.2kg of Bacillus subtilis and 0.3kg of Candida prion;

[0039] S2. Mix corn, soybean meal, rapeseed meal, sawdust, soybean oil, glucose, starter and water evenly and ferment in piles;

[0040] S3. When the temperature rises to 35-40°C, turn the pile for heat dissipation and oxygen circulation for the first time, and cover it with plastic film to control temperature and oxygen;

[0041] S4. When the temperature rises to 35-40°C again, turn the pile for heat dissipation and oxygen circulation for the second time, and cover it with plastic film to control temperature and oxygen;

[0042] S5. When the temperature rises to 35-40°C again, turn the stack for the th...

Embodiment 3

[0049] The preparation of fermented feed raw materials comprises the following steps:

[0050] S1. Weigh 280kg of corn, 130kg of soybean meal, 100kg of rapeseed meal, 90kg of sawdust, 20kg of soybean oil, 15kg of glucose, 1.5kg of starter and 380kg of water;

[0051] The starter consists of 0.4kg of lactic acid bacteria, 0.6kg of Bacillus subtilis and 0.5kg of Candida prion;

[0052] S2. Mix corn, soybean meal, rapeseed meal, sawdust, soybean oil, glucose, starter and water evenly and ferment in piles;

[0053] S3. When the temperature rises to 35-40°C, turn the pile for heat dissipation and oxygen circulation for the first time, and cover it with plastic film to control temperature and oxygen;

[0054] S4. When the temperature rises to 35-40°C again, turn the pile for heat dissipation and oxygen circulation for the second time, and cover it with plastic film to control temperature and oxygen;

[0055] S5. When the temperature rises to 35-40°C again, turn the stack for the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com