High-sensitivity organic photodiode, array formed thereby and preparation method of high-sensitivity organic photodiode

A photodiode, high-sensitivity technology, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the short-wave infrared organic photodiode noise and detection rate limitations, it is difficult to achieve high external quantum efficiency, exciton dissociation driving force reduction Small problems, to achieve the effects of trap-assisted recombination suppression, promotion of dark current and noise spectral density, and improvement of photosensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

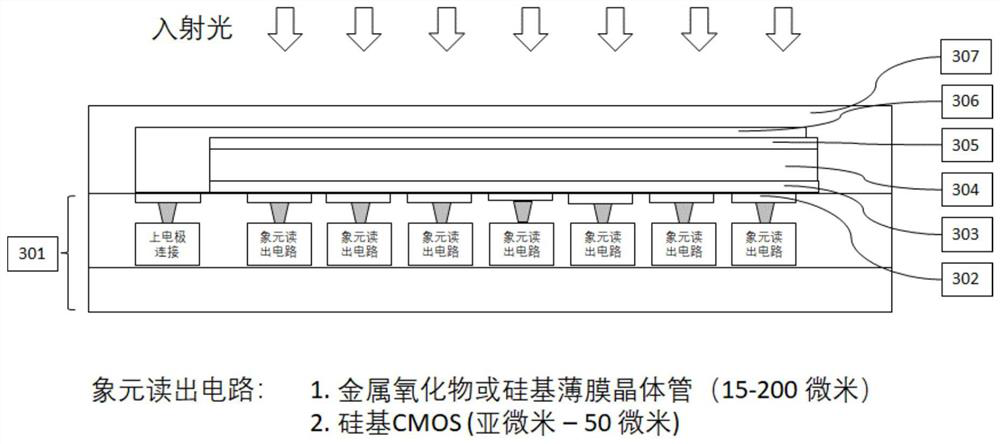

[0144] The device structure of the highly sensitive organic photodiode in this embodiment is as follows figure 1 As shown, from bottom to top are glass substrate (2mm), cathode (150nm), electron transport hole blocking layer (30nm), photosensitive layer (210nm), hole transport electron blocking layer (12nm), anode (150nm) and encapsulation layer.

[0145] Among them, the cathode is made of indium tin oxide (ITO); the electron transport hole blocking layer is made of zinc oxide (the carrier mobility in this material is ~10 -1 cm 2 V -1 S -1 ); the hole transport electron blocking layer is molybdenum oxide (the carrier mobility in this material is ~10 after testing -3 cm 2 V -1 S -1 ); the anode is metal silver; the encapsulation layer is epoxy resin.

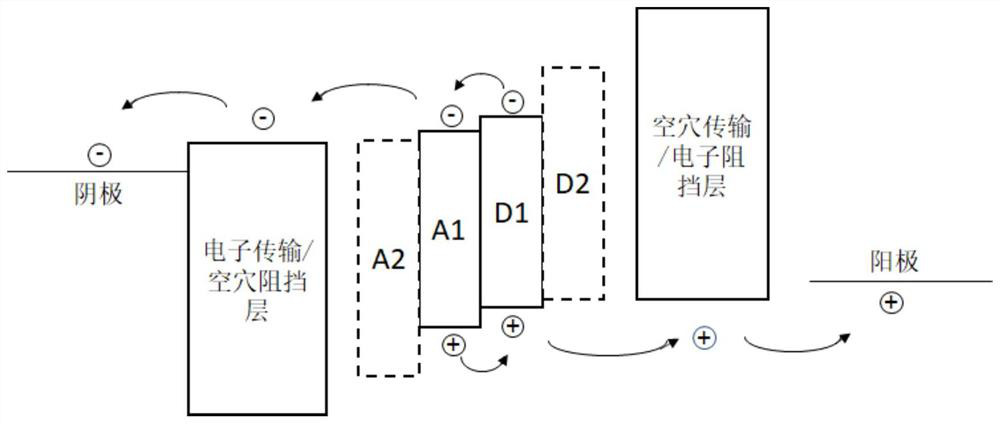

[0146] The photosensitive layer adopts a ternary blended bulk heterojunction structure, which is a nanocrystalline structure. The donor material D1 is PTB7-Th, the acceptor material A1 is COTIC-4F, and the acceptor mat...

Embodiment 2

[0162] The device structure, materials used, and device preparation method in this embodiment are the same as those in Embodiment 1. The only difference is that the acceptor material A2 in Example 1 is replaced by IT-4F, and the mass ratio of D1:A1:A2 is 1:1.2:0.3.

[0163] The energy gap of the acceptor material A2, IT-4F, is calculated to be 1.48eV; its LUMO energy level is -4.14eV; the carrier mobility in this material is tested to be 3×10 -4 cm 2 V -1 S -1 .

[0164] The parameters of other identical materials used are the same as in Example 1.

Embodiment 3

[0166] The device structure, materials used, and device preparation method in this embodiment are the same as those in Embodiment 1. The only difference is that the acceptor material A2 in Example 1 is replaced by PC 71 BM, and the mass ratio of D1:A1:A2 is 1:1.2:0.3.

[0167] Acceptor material A2, PC 71 The energy gap of BM is calculated to be 2.13eV; its LUMO energy level is -4.20eV; the carrier mobility in the material is tested to be 6×10 -4 cm 2 V -1 S -1 ;

[0168] The parameters of other identical materials used are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com