Submersible sand pump

A technology for pumping sand and separating sand, which is applied in the direction of pumps, pump devices, pump components, etc., and can solve problems such as failure, insufficient head flow, and frequent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

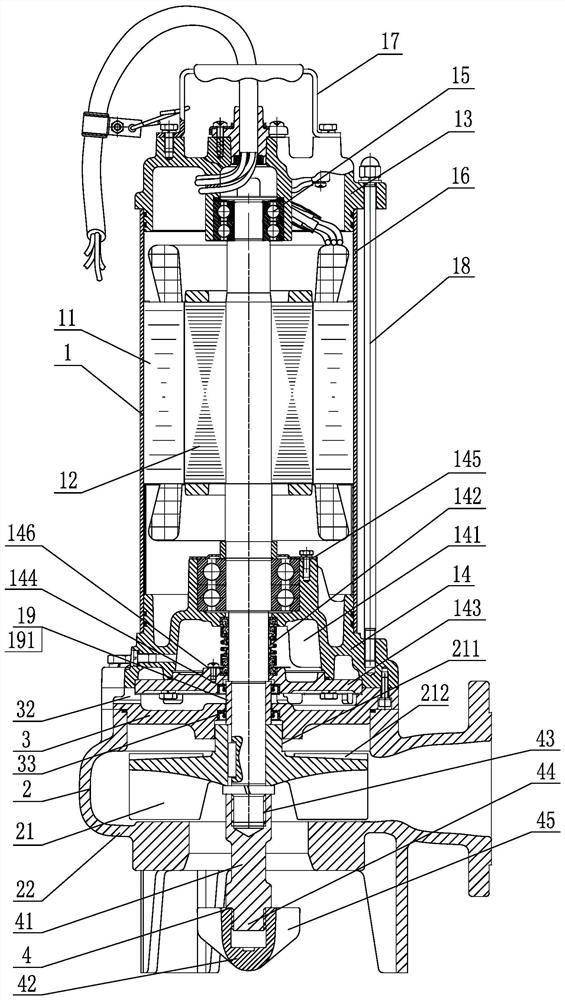

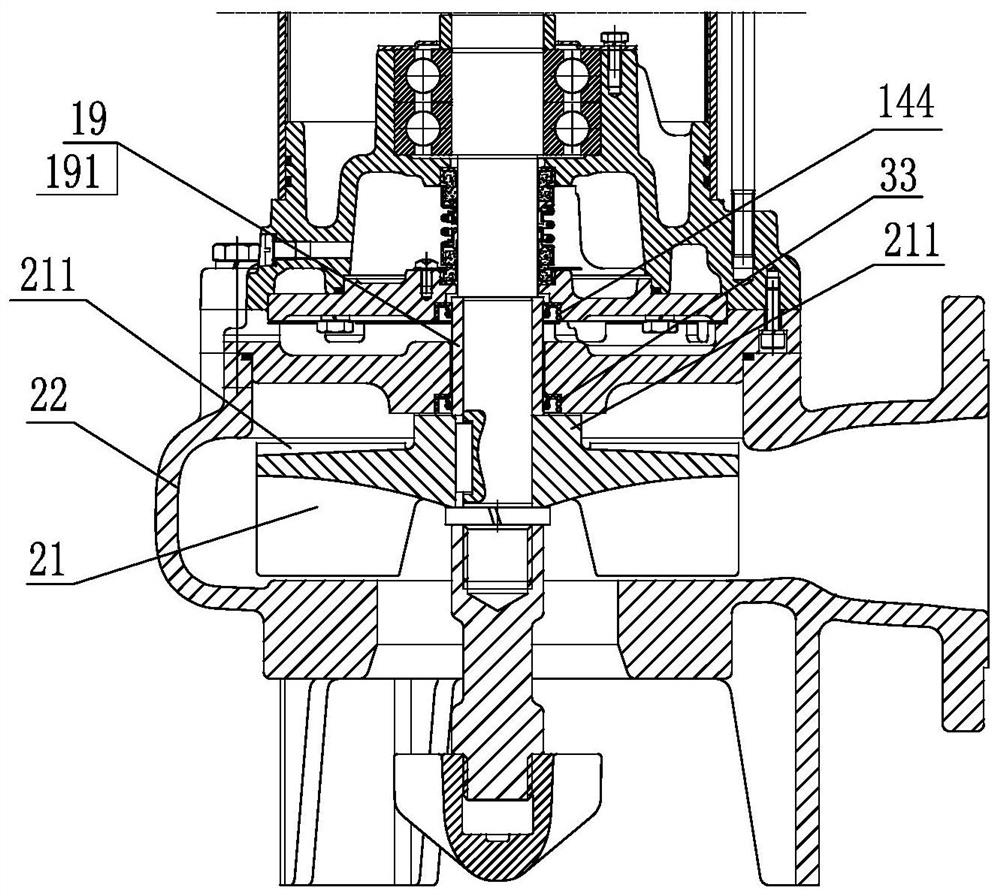

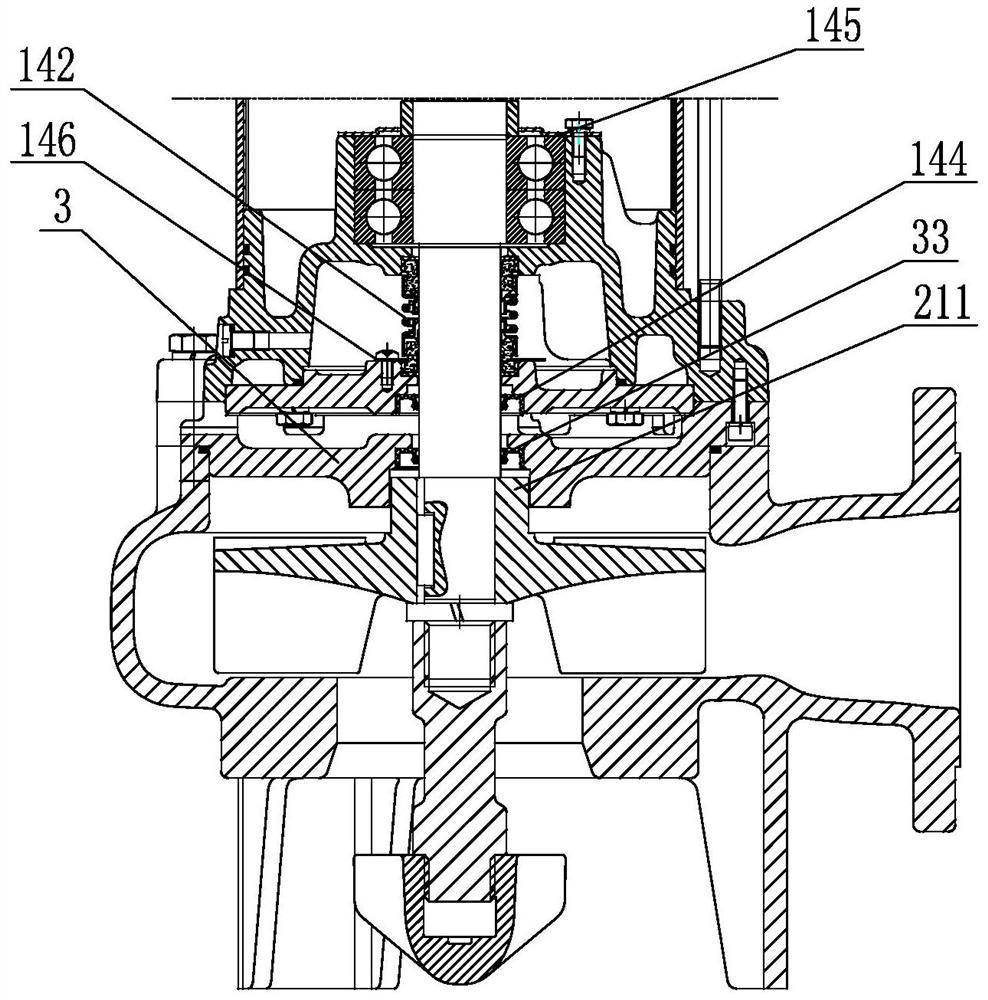

[0036] Depend on Figure 1-3 , shown in 19, the specific embodiment of the submersible sand pump of the present invention is: the submersible sand pump includes a motor 1 and a centrifugal pump body 2 connected together, wherein the motor 1 includes a stator 11, a rotor 12, an upper bearing seat 13, a lower bearing Seat 14, bearings 15 at both ends, motor housing 16, handle 17, and connecting screw 18 connecting upper bearing housing 13 and lower bearing housing 14 at the outside of motor housing 16, wherein lower bearing housing 14 has a mechanical seal cavity 141 and will The mechanical seal cavity 141 is hermetically connected to the cover 143, and the double-end mechanical seal 142 is installed in the mechanical seal cavity 141. The outer central axis of the cover 143 also has an anti-sand seal ring 144. The centrifugal pump body 2 It includes an impeller 21 and a pump volute 22 connected to the rotor 12, and a sand separation tray 3 is installed between the motor 1 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com