Width-adjustable automatic folding mechanism

A folding mechanism and automatic technology, applied in the field of clothing folding, can solve the problems of clothing folding that cannot meet different widths, inconvenient collection of clothing, and loose falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

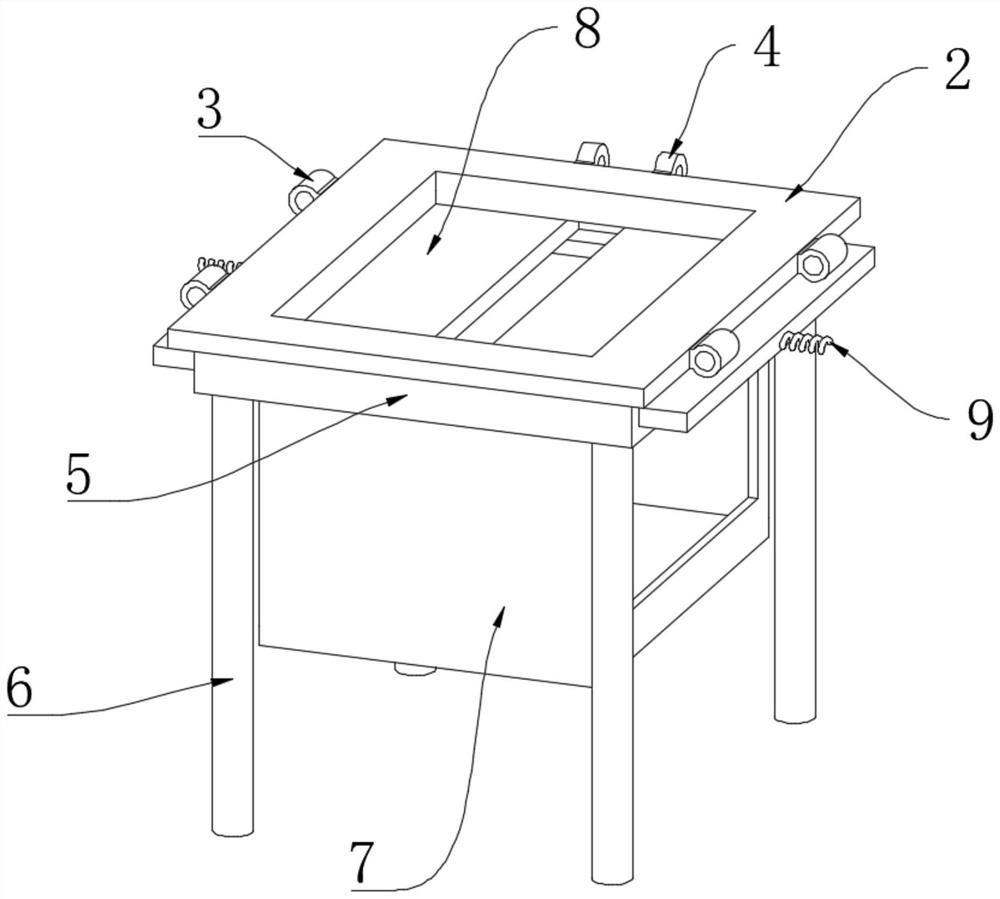

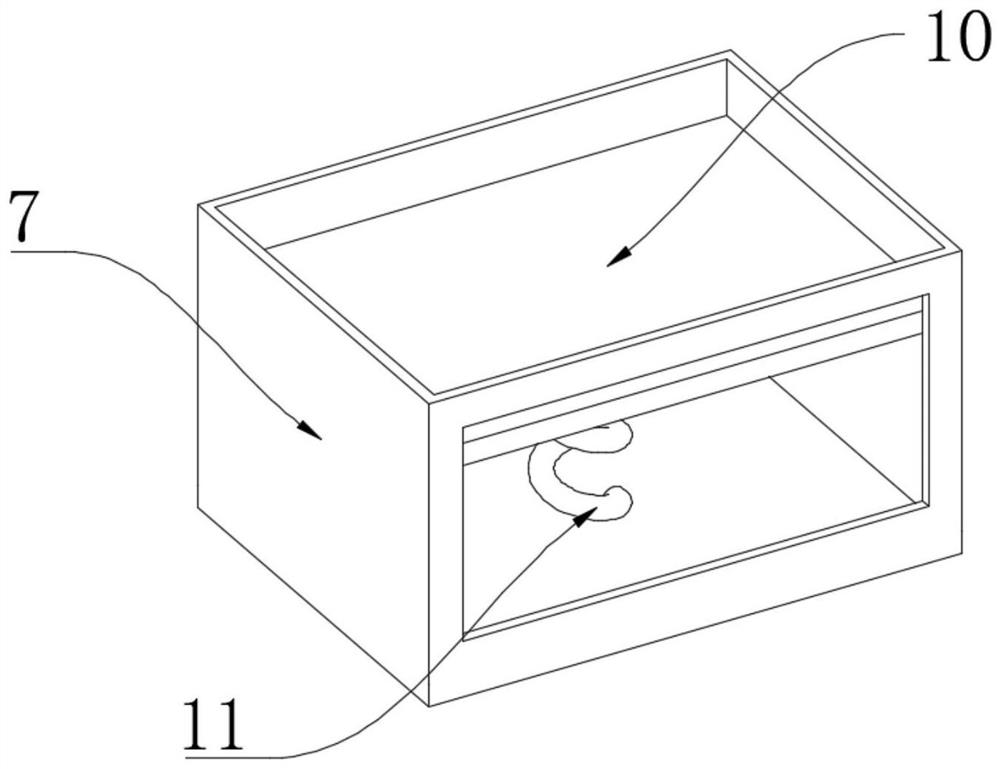

[0034] Such as Figure 1-Figure 3 As shown, a width-adjustable automatic folding mechanism includes an installation box 1, the upper surface and the front of the installation box 1 are without a cover structure, and the bottom of the inner wall of the installation box 1 is fixedly connected with a connecting column 6, which is connected to The top of the column 6 is fixedly connected with the receiving frame 5, the top of the receiving frame 5 is fixedly connected with the installation frame 2, the front and rear side walls of the installation frame 2 are fixedly connected with the sleeve one 3, and the right side wall of the installation frame 2 is fixedly connected with Sleeve 2 4 is arranged, and the outer wall of material receiving frame 5 is provided with empty groove, and the front and rear sides of the empty groove are all slidably connected with material receiving plate 8, and the side of material receiving plate 8 close to the inner wall of installation box 1 is connec...

Embodiment 2

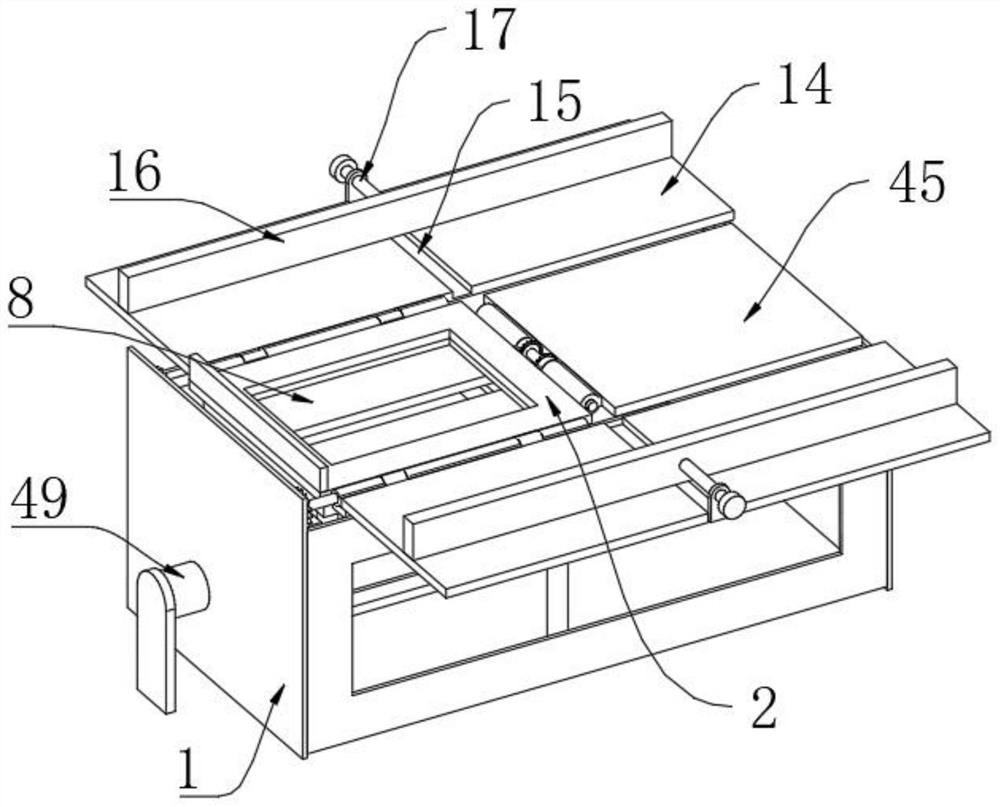

[0050] Such as Figure 11 As shown, it is basically the same as Embodiment 1, the difference is that the front and rear side walls of the installation frame 2 are movably connected with a folding plate 14, and the side of the folding plate 14 close to the installation frame 2 is fixedly connected with a sleeve 3 12, Sleeve three 12 is a segmented structure, sleeve three 12 and sleeve one 3 are on the same horizontal axis, and the inner wall of sleeve three 12 and sleeve one 3 is plugged with bolt shaft one 13, and bolt shaft one 13 is connected to the sleeve The inner wall of three 12 is fixedly connected, the latch shaft one 13 is rotatably connected to the inner wall of the sleeve one 3, the upper surface of the folding plate one 14 is provided with a chute 15, and the upper surface of the folding plate one 14 is slidingly connected with a stop relative to the position of the folding plate one 14 Plate 16, folding plate one 14 is fixedly connected with a positioning plate 18...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com