Method and device for refining copper heavy metal in pickling copper wastewater

A technology for heavy metals and waste water, applied in the fields of metallurgical waste water treatment, chemical instruments and methods, water pollutants, etc., can solve problems such as the inability to achieve a wide range of copper ions, and achieve the effect of solving difficult sewage treatment, good removal effect, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

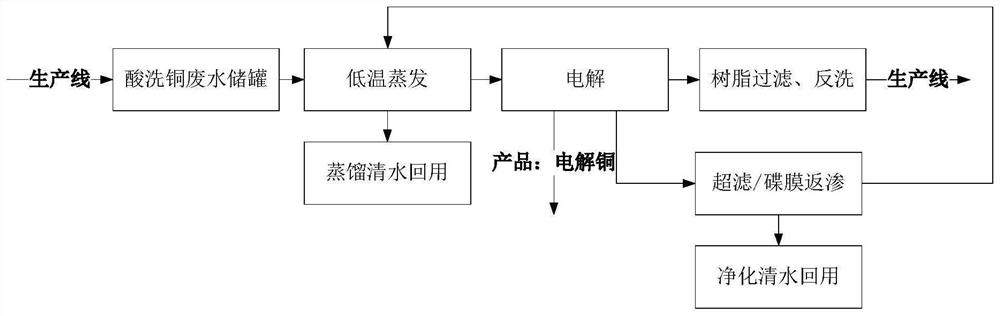

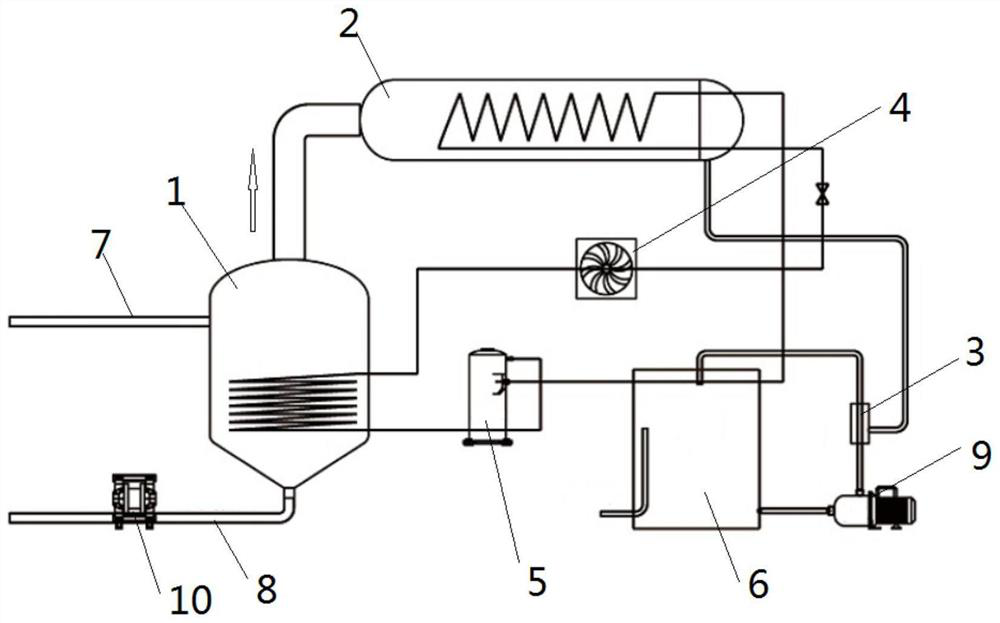

[0067] This embodiment is the use of this process in the pickling copper workshop of Luofan Environmental Protection Technology Co., Ltd., and this embodiment adopts such as figure 1 The process flow chart, that is, the low-concentration pickling copper wastewater in the production line enters the pickling copper wastewater storage tank, and then enters the low-temperature evaporator assembly 2 for low-temperature evaporation, and the pickling copper wastewater concentrated by low-temperature evaporation enters electrolysis, After the electrolytic extraction of copper is completed, if the copper content does not meet the discharge standard, the copper is collected by resin filtration, and the resin that collects copper ions is backwashed to obtain copper-containing waste liquid, which then enters the next round of low-temperature evaporation and electrolysis. If it meets the standard, it is directly discharged or Purified water is reused after back osmosis through the ultrafilt...

Embodiment 2

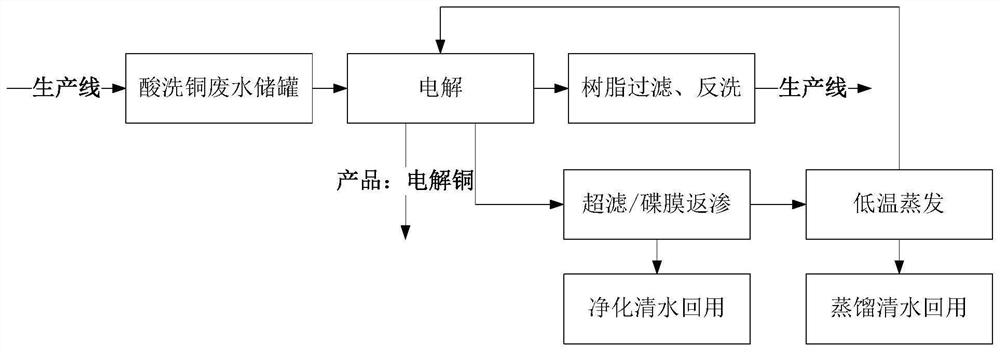

[0075] This embodiment is the use of this process on the pickling copper recovery line of Zhejiang Shaoxing Jiutian Umbrella Industry Co., Ltd.

[0076] Its online pickling copper wastewater was originally replaced by sponge copper, which produced low value, hydrochloric acid and nitric acid could not be reused, and the sewage treatment resulted in a large amount of solid waste; 220 tons of pickling waste liquid per month formed 6 tons of solid waste, Outsourcing costs remain high. Introducing the electrolysis process of this technology, 220 tons of copper with a copper ratio of 0.8% are directly refined to recover 1.7 tons of copper per month; the acid is recovered and recycled, and an economic benefit of 150,000 yuan per month is realized.

Embodiment 3

[0078] This embodiment is the use of this process in Xinfeng Xunjiexing Circuit Technology Co., Ltd.

[0079] The copper waste liquid of its online pickling circuit board was directly outsourced, and the added value was not high. The electrolysis process was introduced, and the copper content of 40 tons / day was 10.8%. 4.3 tons / month of copper was directly refined and recycled; acid recovery and recycling Using it, the economic benefit is 300,000 yuan / day, and the annual energy recovery of the project saves more than 100 million yuan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com