Production process and system for preparing vaterite gelling building raw material by utilizing carbon capture technology

A production process and production system technology, which is applied in the field of building materials and flue gas treatment, to achieve the effect of reducing the amount of use, simple and not harsh reaction conditions, and high dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. Obviously, the described embodiments are only some of the embodiments of the present invention, rather than all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

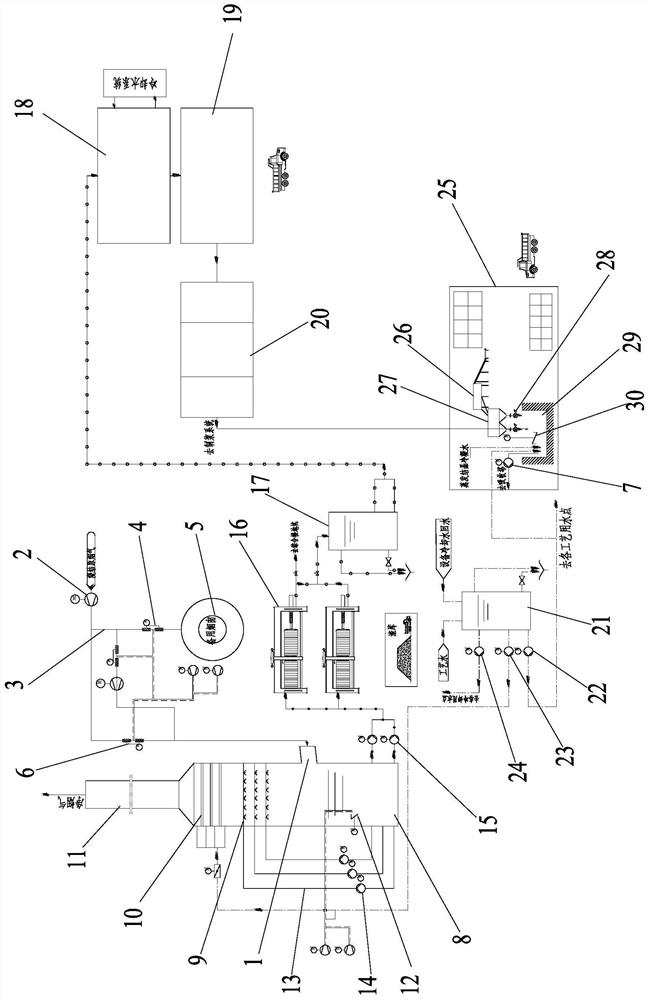

[0034] The invention provides a production process and production system for preparing vaterite cemented building materials using carbon capture technology, referring to figure 1 Shown structural representation, production technique of the present invention comprises the steps:

[0035] (1) Use the pulping system to prepare carbon dioxide absorbent for carbon capture: mix ethylenediamine and 1,3-butanediol in the pulping system at a mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com