Far-end passage catheter and manufacturing method thereof

A manufacturing method and catheter technology, applied in the direction of catheters, coatings, etc., can solve the problems of thin-walled tubing, such as easy deformation, poor vascular transport, and poor concentricity, and achieve reduced processing surface defects and internal voids, good vascular compliance and Passability, stable and controllable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

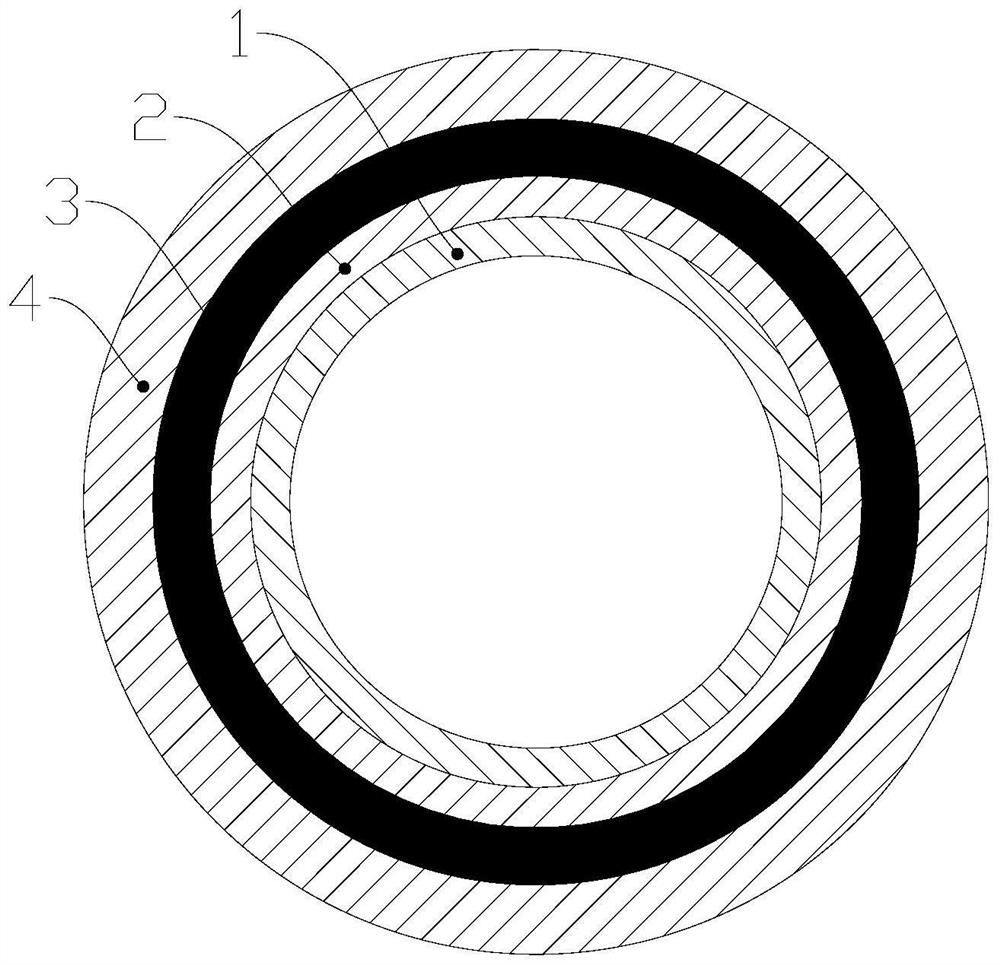

[0040] A method of making a distal access catheter, comprising the following steps:

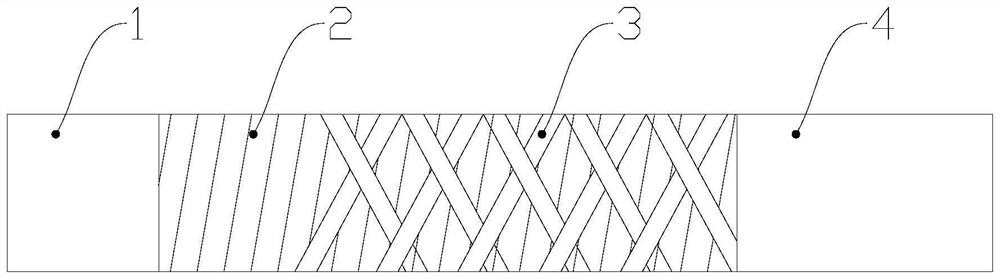

[0041] S1. Coating the inner layer: First, coat the PTFE coating on the upper surface of the metal tube mandrel, the coating thickness is 20 μm, and then process the spring layer on the surface of the PTFE coating, the thickness of the spring layer is 25 μm, and secondly, in the spring The surface of the layer is cross-woven with metal flat wires, and the thickness of the cross-braid is 50 μm to obtain the first semi-finished product;

[0042] S2. Coating the outer layer: Then use an online extruder with a mandrel to extrude the first plastic layer on the surface of the first semi-finished product, the first plastic layer is TPU; use the rollers to extrude the surface at the rear end of the extrusion die Extruding, the molten first plastic layer is wrapped on the surface of the braided layer during online extrusion, the thickness of the first plastic layer is 75 μm, and the second semi-finish...

Embodiment 2

[0046] A method of making a distal access catheter, comprising the following steps:

[0047] S1. Coating the inner layer: First, coat the PTFE coating on the upper surface of the metal tube mandrel, the coating thickness is 10 μm, and then process the spring layer on the surface of the PTFE coating, the thickness of the spring layer is 30 μm, and secondly, the The surface of the layer is cross-braided with metal flat wires, and the thickness of the cross-braid is 60 μm to obtain the first semi-finished product;

[0048] S2. Coating the outer layer: Then use an online extruder with a mandrel to extrude the first plastic layer on the surface of the first semi-finished product. The first plastic layer is made of nylon material; The surface is extruded, and the molten first plastic layer is wrapped on the surface of the braided layer during online extrusion. The thickness of the first plastic layer is 80 μm, and the second semi-finished product is obtained; The outer layer of pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Frequency | aaaaa | aaaaa |

| Spot size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com