Method for billow forming magnesium alloy thin plate

A technology of inflatable forming and magnesium alloy plates, which is applied in the field of magnesium alloy air inflatable manufacturing, can solve the problems of excessive burr waste, difficulty in achieving lightness and thinness, and high manufacturing costs, and achieves low forming pressure, low manufacturing cost, and smooth process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0010] Specific Embodiment 1: In this embodiment, the magnesium alloy thin plate is subjected to inflation forming as follows: a. Heating process: the magnesium alloy sheet is loaded into a mold, and then the sheet is heated to an inflation forming temperature of 200-400°C, The holding time is 10 to 60 minutes to ensure that the sheet is heated evenly; b. Pressurization process: apply a compressive load on the mold to press the die, ventilation plate and sheet; c. Expansion process: to the mold Fill the gas with a pressure of 0.1-0.8 MPa and keep the pressure for 10-30 minutes to make the sheet expand into the mold cavity; d. Forming process: continue to increase the air pressure into the mold to make it reach 1~1.5MPa, keep the pressure for 10~30 minutes, make the sheet material gradually adhere to the surface of the mold cavity, until the mold is completely filled, forming a part with the same surface as the mold, and finally cooled and demoulded to complete the finished prod...

specific Embodiment approach 2

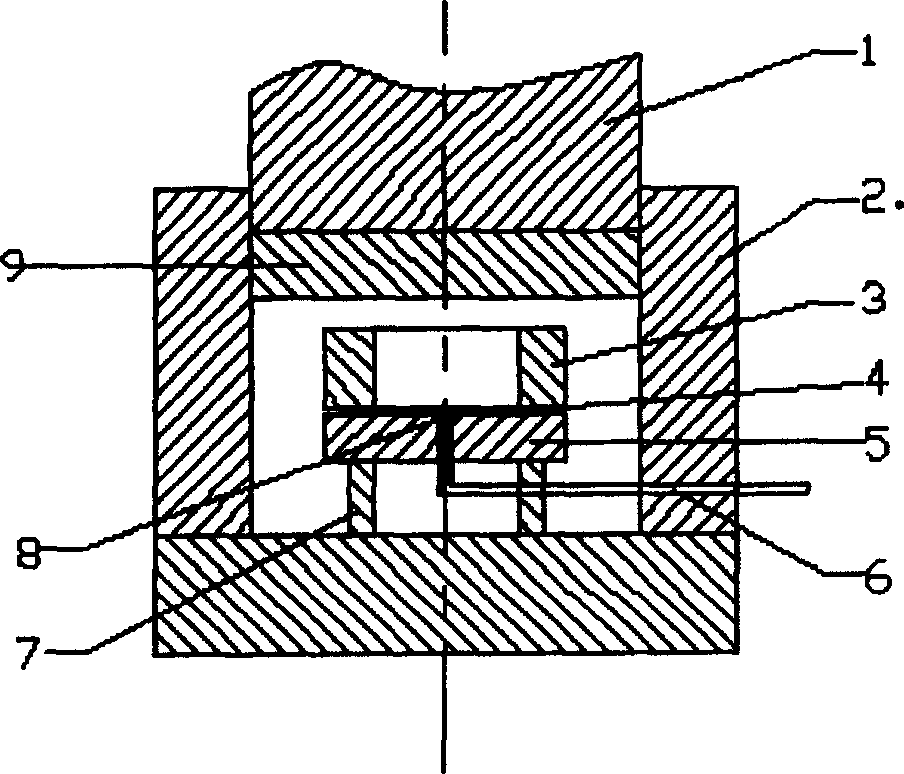

[0011] Embodiment 2: The plate material of this embodiment is a Mg—Zn—Zr thin plate 4 with a thickness of 1 mm and a grain size of 8 μm. The heating process is carried out in a superplastic molding machine (such as figure 1 As shown), the superplastic molding machine is composed of a furnace body 2, an indenter 1 above the furnace body 2, a cover plate 9 connected to the indenter 1, and a support frame 7 placed inside the furnace body 2. The forming mold structure consists of Die 3, ventilation plate 5, gas filling port 8 and vent tube 6 are formed, and die 3 and vent plate 5 are arranged up and down, and gas charging port 8 is opened on the ventilation plate 5, and vent tube 6 communicates with gas charging port 8. Ventilation plate 5 is placed on the support frame 7, sheet material 4 is placed on the ventilation plate 5, and die 3 is placed on the sheet material 4. Then heat the sheet material 4 to the forming temperature of 300°C, keep it warm for 30 minutes, move the pres...

specific Embodiment approach 3

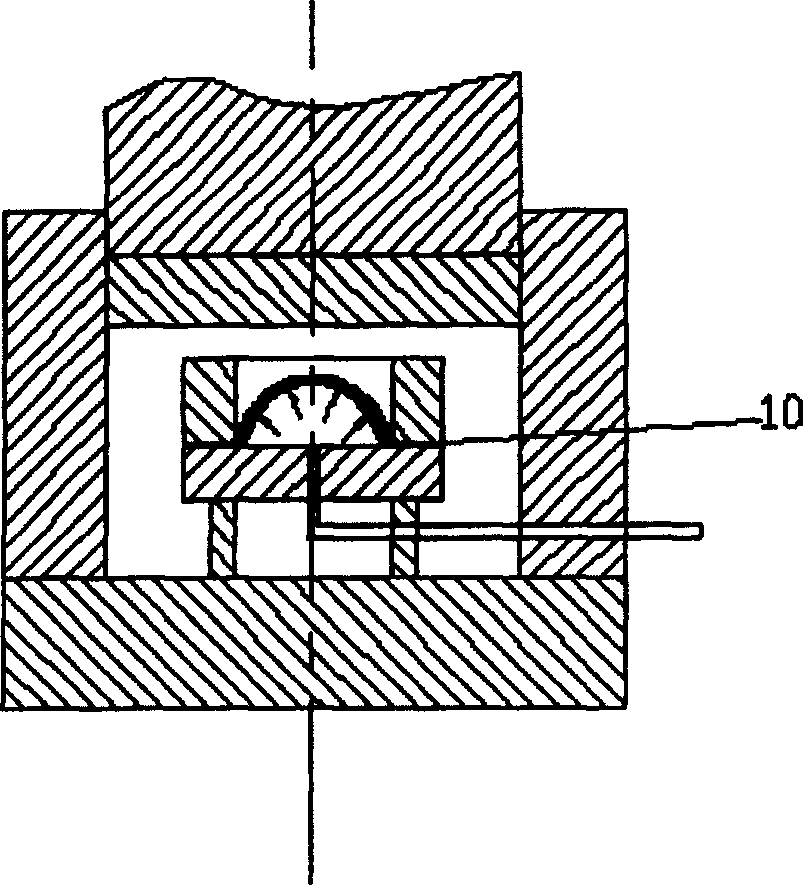

[0012] Embodiment 3: The sheet material of this embodiment is a 0.8 mm thick Mg—Zn—Zr sheet 4 with a grain size of 7 μm. The heating process is carried out in a superplastic molding machine (such as figure 1 shown), put the sheet 4 on the ventilation plate 5, and put the die 3 on the sheet 4, then heat the sheet 4 to the forming temperature of magnesium alloy at 300°C, keep it warm for 30 minutes, and place the indenter 1 and the cover plate 9 move down until the mold die 3, the vent plate 5 and the sheet material 4 are pressed tightly; the gas filled into the vent plate 5 during the expansion process is argon, and its pressure is 0.1MPa, keeping Press for 20 minutes to make the sheet material 4 produce suitable plastic deformation; in the molding process, continue to add air pressure to the ventilation plate 5 to 0.9MPa, and keep the pressure for 10 minutes to make the sheet material fully fill the mold (such as figure 2 Shown); finally release the argon in the molded part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com