Spiral reinforced hose

A hose and spiral technology, which is applied in the field of spiral reinforced hoses, can solve the problems of difficulty in purchasing extended monofilaments with thick diameters, lack of manufacturers, and reduced productivity, and achieves low expansion, low price, and improved pressure resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

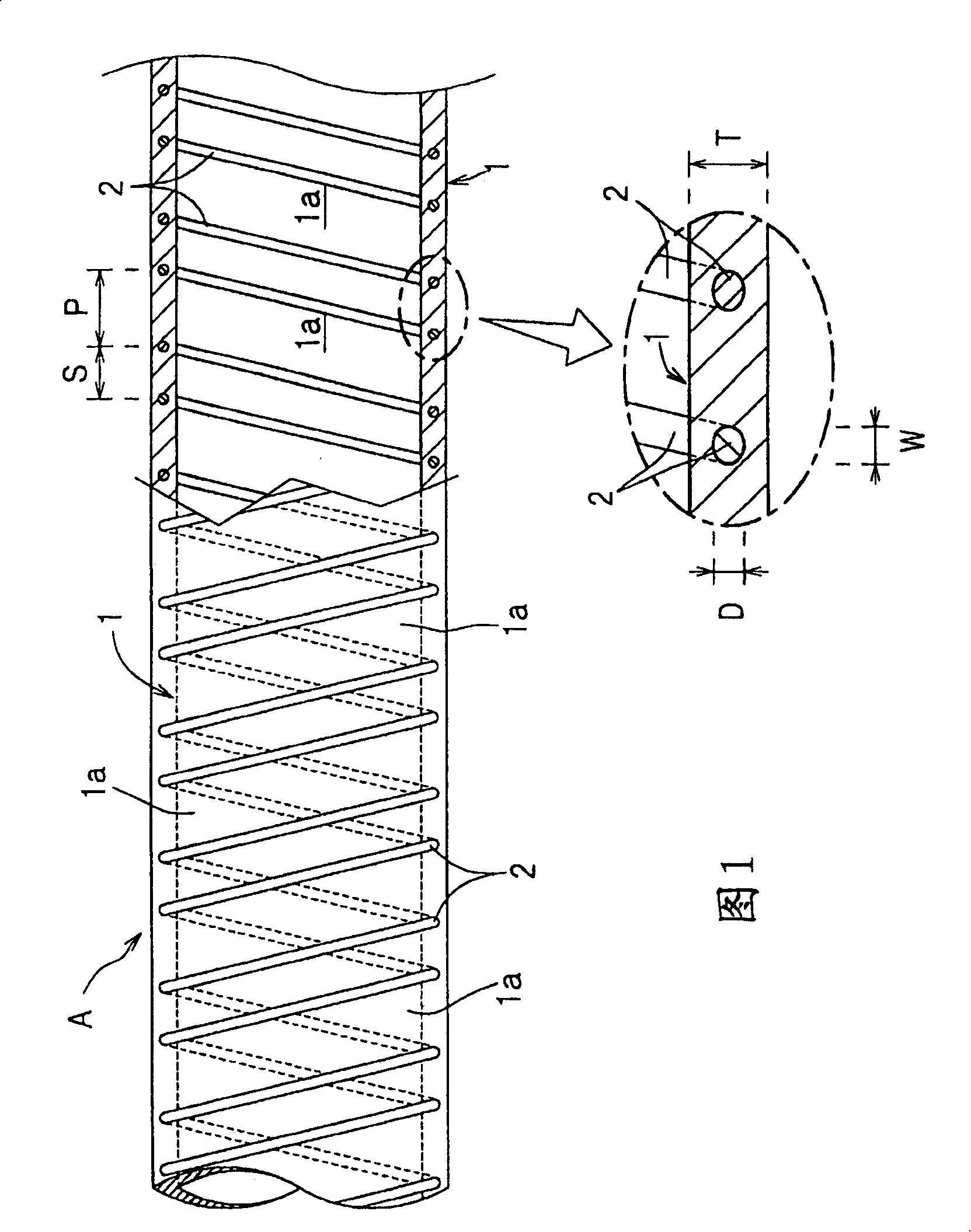

Embodiment 1

[0034] In this embodiment 1, as shown in Figure 1, the hose body 1 is formed from a transparent or translucent material that can see through the inside. The filaments 2, 2 are wound in a helical shape in the axial direction of the hose at equal intervals, and at the same time, the cross-sectional shape of these extended monofilaments 2, 2 is formed into an ellipse or the like, and the core width dimension W is larger than the core thickness dimension D. flat shape.

[0035] The above-mentioned hose body 1, as shown in Publication No. 63-46783, is composed of an inner layer and an outer layer, and can be formed by inserting and winding two extended monofilaments 2, 2 between these inner layers and outer layers. As the spiral reinforced hose A, or as shown in JP-A-50-31198, by a well-known hose manufacturing method, a strip-shaped body having two extended monofilaments 2, 2 is wound into a helical shape, and the The adjoining surfaces are bonded to each other to form a spiral r...

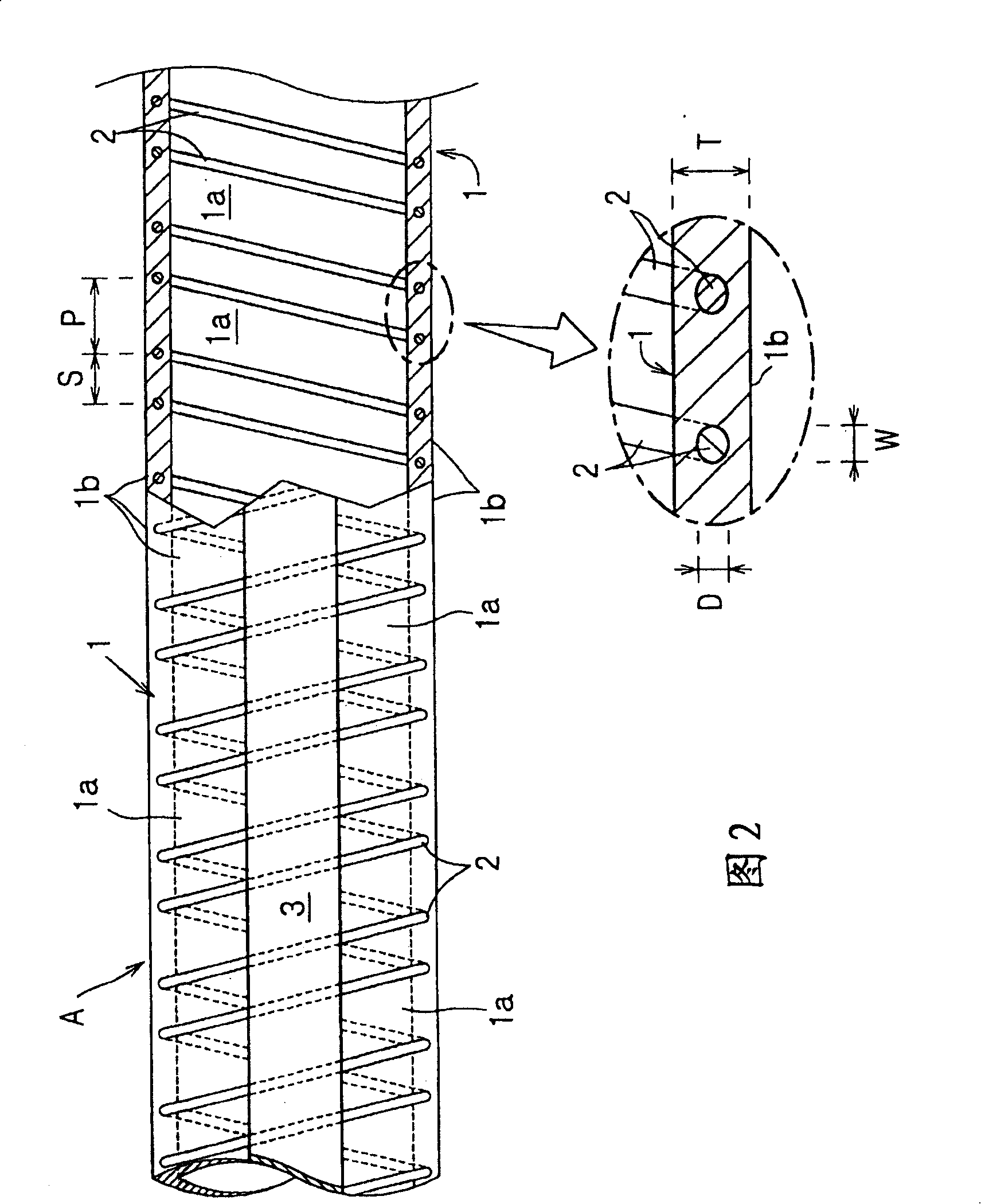

Embodiment 2

[0047] In the second embodiment, as shown in FIG. 2, on the outer surface 1b of the hose body 1, an identification line 3 extending in the axial direction is provided, and the color of the identification line 3 is different from the color of the hose body 1. This is different from Embodiment 1 shown in FIG. 1 above, and other structures are the same as Embodiment 1 shown in FIG. 1 .

[0048] The above-mentioned identification line 3, for example, extrudes thermoplastic resins such as vinyl chloride resin or polyethylene, which is of the same quality and different color as the hose body 1, on the outer surface 1b of the hose, so that the two are integrated, or will be integrated with the hose body 1b. The body 1 is made of thermoplastic resin with the same quality and different colors, and is thermocompression-bonded on the outer surface 1b of the hose, so that the two are integrated.

[0049] In the example figure, although there is only one identification line 3 extending str...

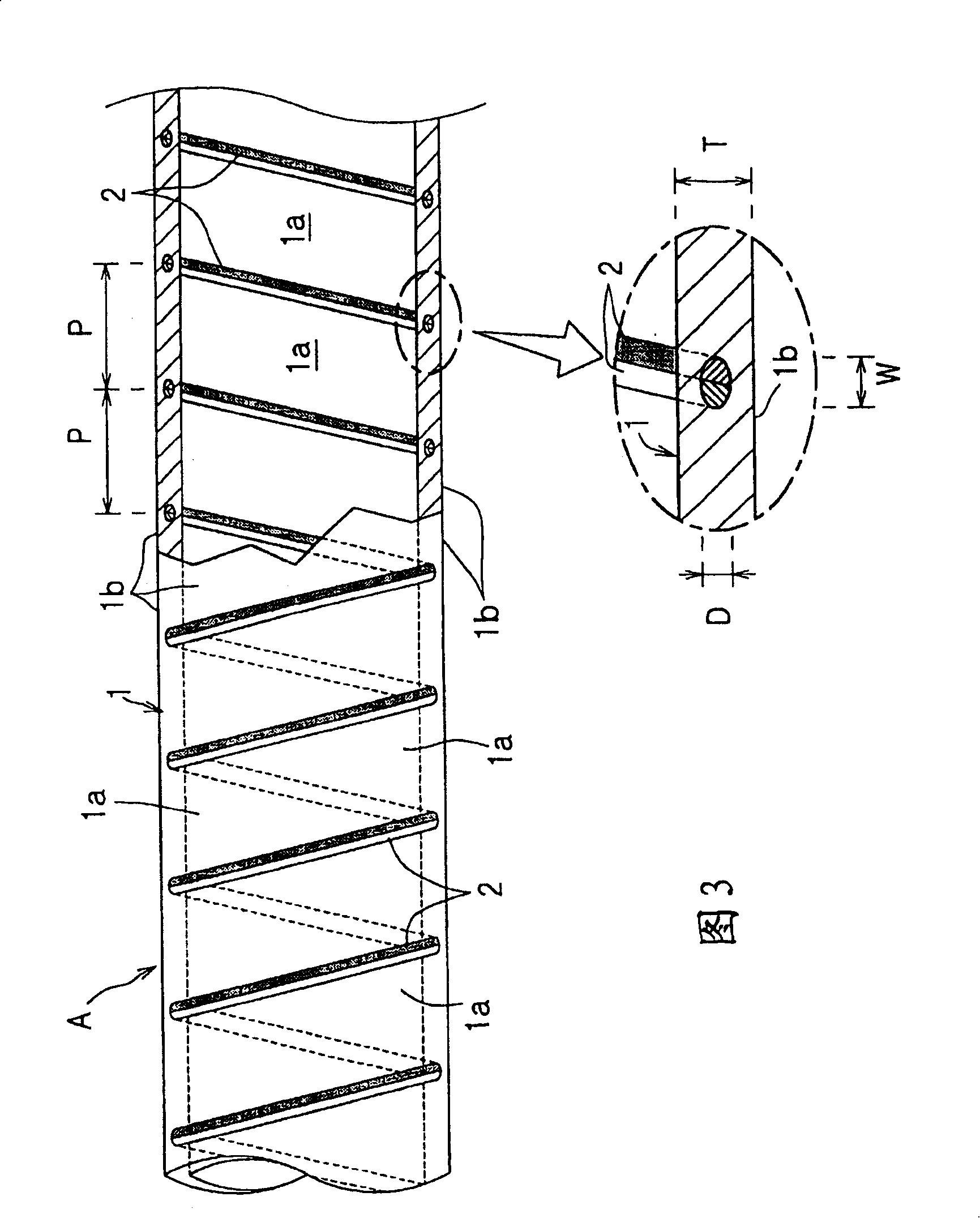

Embodiment 3

[0053] In this embodiment 3, as shown in FIG. 3, in addition to changing the colors of the two extended monofilaments 2, 2 arranged axially toward the above-mentioned hose, the colors of these extended monofilaments 2, 2 can be seen from the outside of the hose body 1. The structure of the color is different from that of Example 1 shown in FIG. 1 above, but the other structures are the same as those of Example 1 shown in FIG. 1 .

[0054] For example, when at least the outer surface of one drawn monofilament 2 is formed in white, it is preferable to form at least the outer surface of the other drawn monofilament 2 in a clearly distinguishable combination such as green, red, or blue other than white.

[0055] In addition, in the illustrated example, the pitch S between the two stretched monofilaments 2, 2 aligned in the axial direction is set to 0 and abutted, and the cross-sectional shape of the two abutted states is formed into an ellipse or the like, And make it a flat shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com