A kind of automatic tracing method and system for sorting leaf non-smoke substances

An automatic technology for non-smoke substances, applied in manufacturing computing systems, chemical instruments and methods, tobacco, etc., can solve the problems of untraceable sorting of non-smoke substances and inability to accurately screen, so as to improve efficiency, correctness, and structure Simple, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

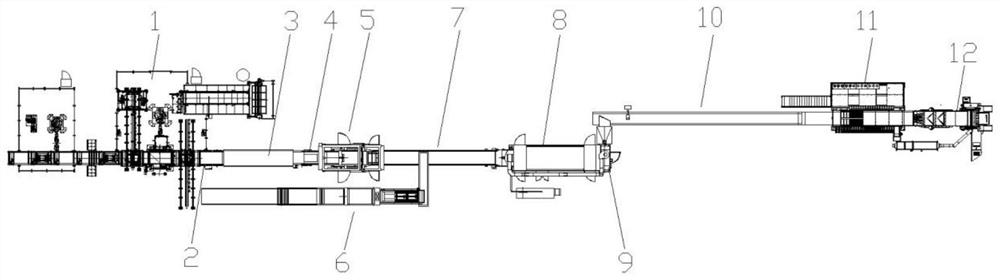

[0049] Example 1 provides an automatic traceability method for sorting non-smoke substances in leaves, see Figure 1 to Figure 6 , which mainly includes the following steps:

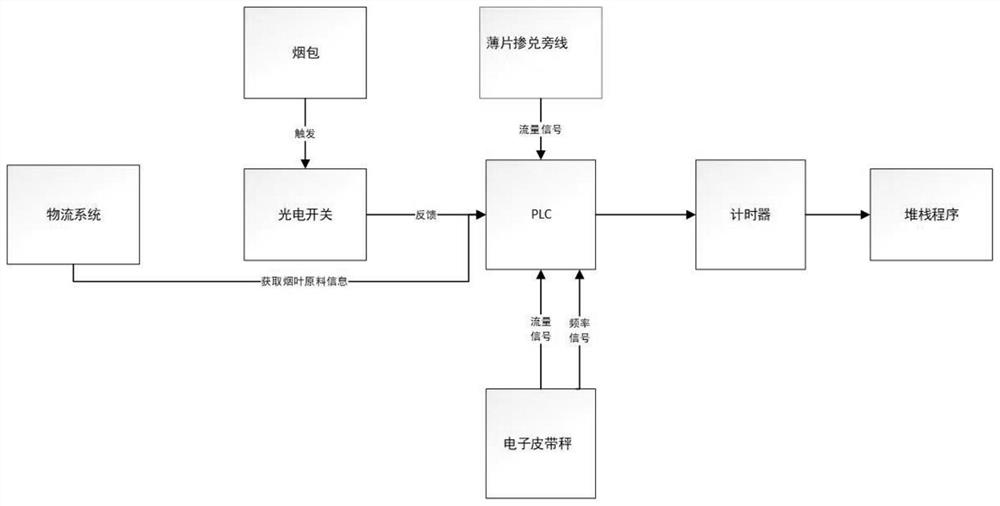

[0050] When the cigarette packs are transported from the logistics equipment 1 into the production line, the detection equipment installed at the entrance of the production line detects the in-position signal of the cigarette packs and sends them to the PLC system;

[0051] The PLC system starts timing after receiving the cigarette pack in-position signal, and sends trigger information to the tobacco leaf raw material information transmission system;

[0052] After receiving the trigger information, the tobacco leaf raw material information transmission system obtains the tobacco leaf raw material information from the logistics equipment;

[0053] Obtain the injection pressure signal of the optical sorter 13 when sorting non-smoke substances through the sorting signal output system, and transmit it to t...

Embodiment 2

[0077] Example 1 provides an automatic traceability system for sorting non-smoke substances in leaves, see Figure 1 to Figure 6 , including: PLC system, tobacco raw material information transmission system, sorting signal output system, image acquisition and processing system, information locking processing system, online automatic sampling device and sound and light alarm device 26 . The automatic tracing system for sorting leaf non-smoke substances provided in Example 2 is used to implement the steps in the automatic tracing method for sorting non-smoke substances in leaves as described in Embodiment 1.

[0078] Wherein, the sorting signal output system includes a pressure transmitter 18, and the pressure transmitter 18 is installed on the compressed air pipeline 19 of the ejector of the optical sorter; On the pressure reducing valve 20 of the compressed air line 19 of the optical sorting 13. The image acquisition and processing system includes a first camera 16 and a seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com