Preparation method of red soup type hotpot oil

A red soup type, hot pot technology, applied in the field of edible oil, can solve the problems of not meeting the needs of people's health, single function of edible oil, etc., and achieve the effects of killing nematodes with physiological activity, low cholesterol content, and relieving pain in confidants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

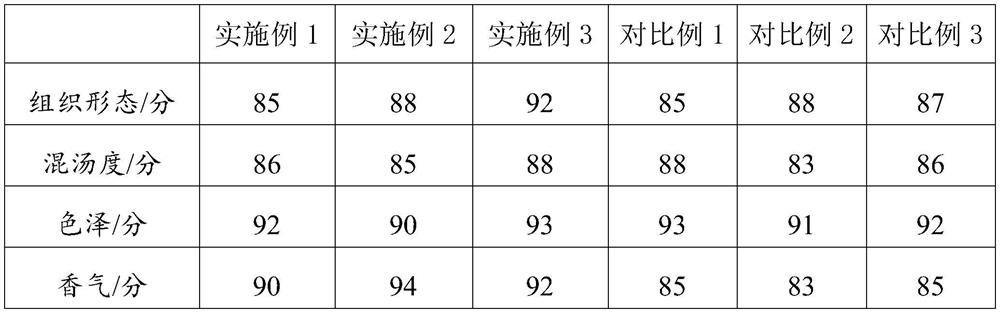

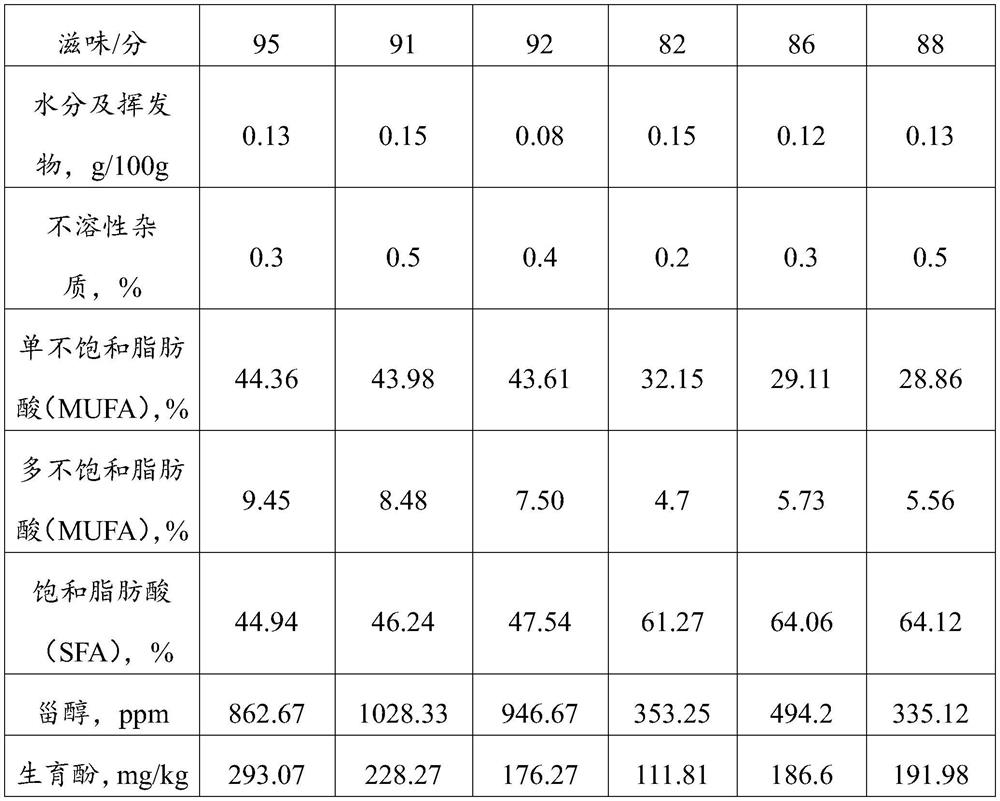

Examples

Embodiment 1

[0024] (1) Heat 10g tallow, 10g sheep oil, 10g peanut oil, and 10g palm oil respectively in a water bath at 60°C, then add 0.4g of citric acid with a concentration of 50wt% to butter, sheep oil, peanut oil, and palm oil respectively solution and 0.4g of water, first ultrasonic treatment at 200W power for 10min, stop for 30s, then ultrasonic treatment at 300W for 30s, stop for 30s, finally ultrasonic treatment at 200W for 10min, and finally centrifuge at 4500r / min for 10min to prepare the pre- Processed tallow, suet, peanut oil, palm oil;

[0025] (2) In parts by weight, 6 parts of star anise, 6 parts of licorice, 5 parts of sweet scorpion, 7 parts of kaempferia, 5 parts of lemongrass, 5 parts of clove, 8 parts of orange peel, 6 parts of nutmeg, 5 parts of fennel, 6 parts of dried ginger, 7 parts of yellow osmanthus, 6 parts of cinnamon bark, 5 parts of amomum, 6 parts of coriander seeds, 8 parts of gardenia, 5 parts of vanilla, 8 parts of hawthorn, 5 parts of fragrant fruit, 5...

Embodiment 2

[0030] (1) Heat 10g tallow, 10g sheep oil, 10g peanut oil, and 10g palm oil respectively in a water bath at 70°C, then add 0.4g of citric acid with a concentration of 50wt% to butter, sheep oil, peanut oil, and palm oil respectively solution and 0.4g of water, first ultrasonic treatment at 200W power for 10min, stop for 30s, then ultrasonic treatment at 300W for 30s, stop for 30s, finally ultrasonic treatment at 200W for 15min, and finally centrifuge at 5500r / min for 10min to prepare the pre- Processed tallow, suet, peanut oil, palm oil;

[0031] (2) In parts by weight, 6 parts of star anise, 6 parts of licorice, 7 parts of sweet scorpion, 8 parts of kaempferia, 8 parts of lemongrass, 7 parts of clove, 8 parts of orange peel, 10 parts of nutmeg, 9 parts of scorpion, 6 parts of dried ginger, 7 parts of yellow osmanthus, 8 parts of cinnamon bark, 6 parts of amomum, 5 parts of caraway seeds, 7 parts of gardenia, 6 parts of vanilla, 6 parts of hawthorn, 7 parts of fragrant fruit, ...

Embodiment 3

[0036] (1) 10g tallow, 10g sheep oil, 10g peanut oil, and 10g palm oil are heated in a water bath at 70°C respectively, and then 0.5g of citric acid is added to the butter, sheep oil, peanut oil, and palm oil with a concentration of 50wt%. solution and 0.5g of water, first ultrasonic treatment at 200W power for 10min, stop for 30s, then ultrasonic treatment at 300W for 30s, stop for 30s, finally ultrasonic treatment at 200W for 20min, and finally centrifuge at 4500r / min for 10min to prepare the pre- Processed tallow, suet, peanut oil, palm oil;

[0037] (2) In terms of parts by weight, 5 parts of star anise, 7 parts of licorice, 80 parts of Gan Si, 6 parts of kaempferia, 8 parts of lemongrass, 10 parts of cloves, 10 parts of orange peel, 7 parts of nutmeg, 8 parts of fennel, 7 parts of dried ginger, 8 parts of yellow osmanthus, 6 parts of cinnamon bark, 7 parts of Amomum amomum, 5 parts of coriander seeds, 5 parts of gardenia, 6 parts of vanilla, 8 parts of hawthorn, 6 parts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com