Flame-retardant magnesium alloy and method for producing same

A manufacturing method and magnesium alloy technology, applied in the field of flame-retardant magnesium alloy and its manufacture, can solve problems such as molten metal combustion, and achieve the effects of inhibiting combustion, inhibiting ablation, and improving ablation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

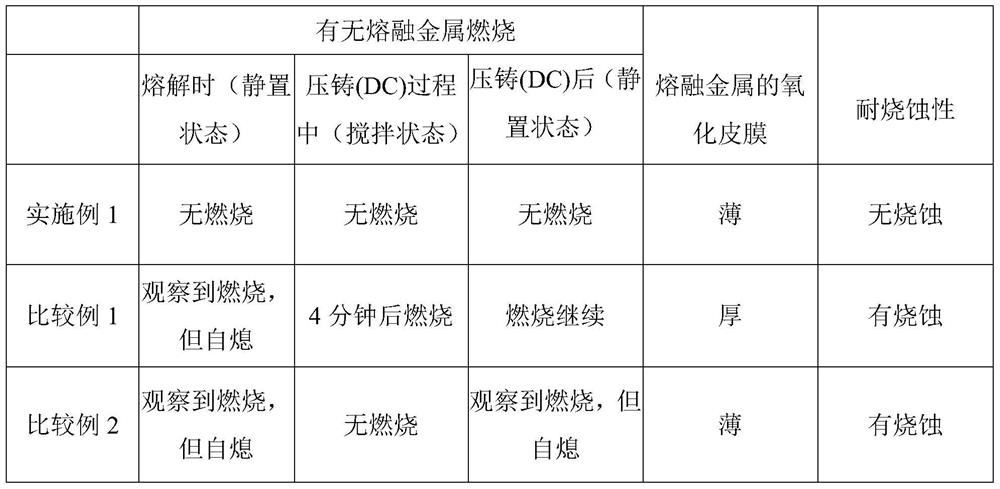

[0080] Next, the present invention will be described in more detail based on examples, but the present invention is not limited thereto. In addition, unless otherwise specified, "ppm" described in Examples and Comparative Examples means "ppm by mass".

[0081]

[0082] [Making of molten metal]

[0083] A metal material in which 4.5% by mass of Al, 4.0% by mass of Ca, 0.3% by mass of Si, 0.3% by mass of Mn, and 0.6% by mass of mischmetal (Mm) were added to Mg was inserted into the crucible, and placed in the Ar High-frequency induction melting is carried out in the atmosphere, and the molten alloy (molten metal) is obtained by melting at a temperature of 750 to 850°C.

[0084] [Making of castings]

[0085] Next, the obtained molten alloy (molten metal) is poured into a mold and cast, and an engine block is produced by die casting (DC) casting.

[0086] Next, the obtained engine block was heat-treated at 300° C. for 4 hours to obtain a heat-treated engine block.

[0087] The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com