Resin molded body production method

A resin molded body, a technology for manufacturing method, applied in the direction of coating, etc., can solve the problems such as insufficient reinforcement effect of cellulose nanofibers, deterioration of cellulose nanofibers, etc., and achieve good mechanical strength, anisotropy of physical properties and warpage. The effect of less curvature and coloring suppression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

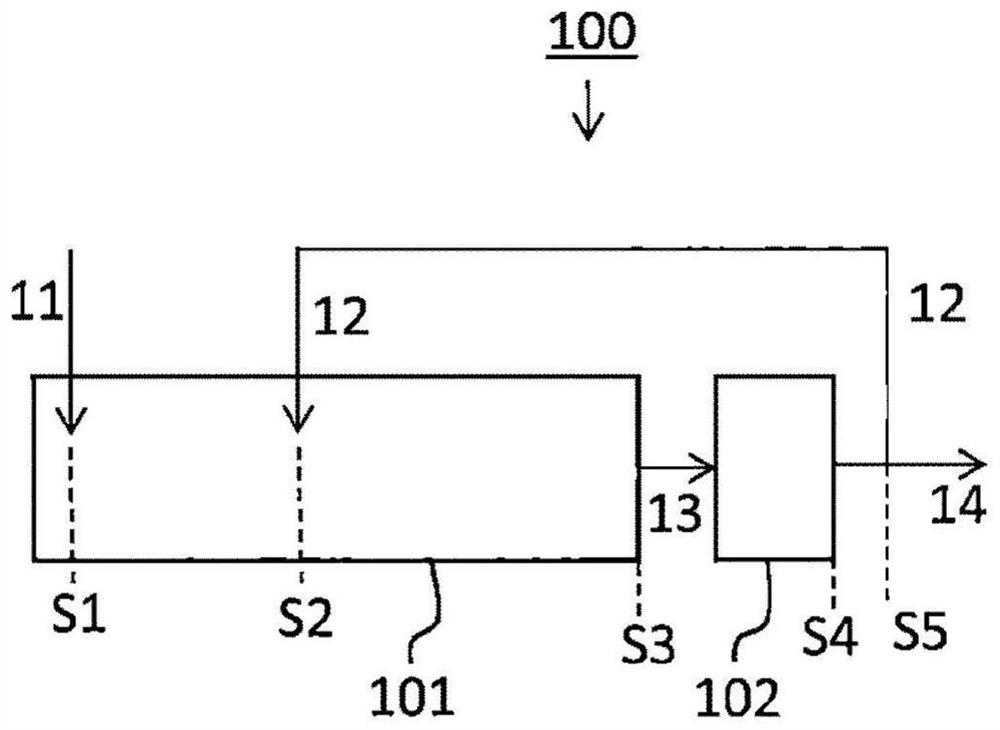

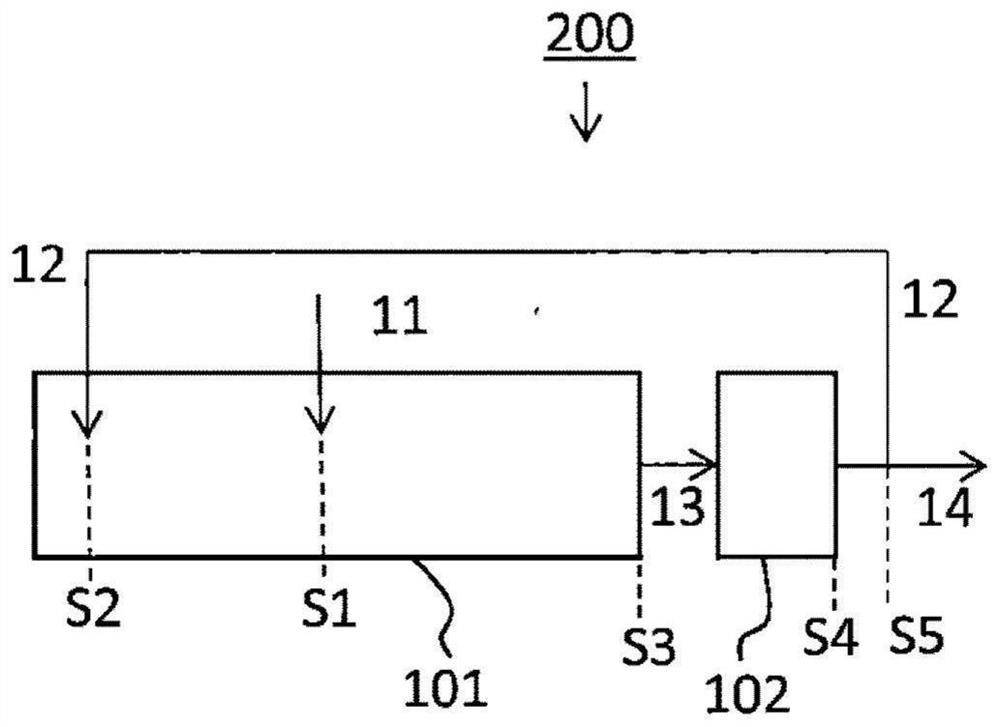

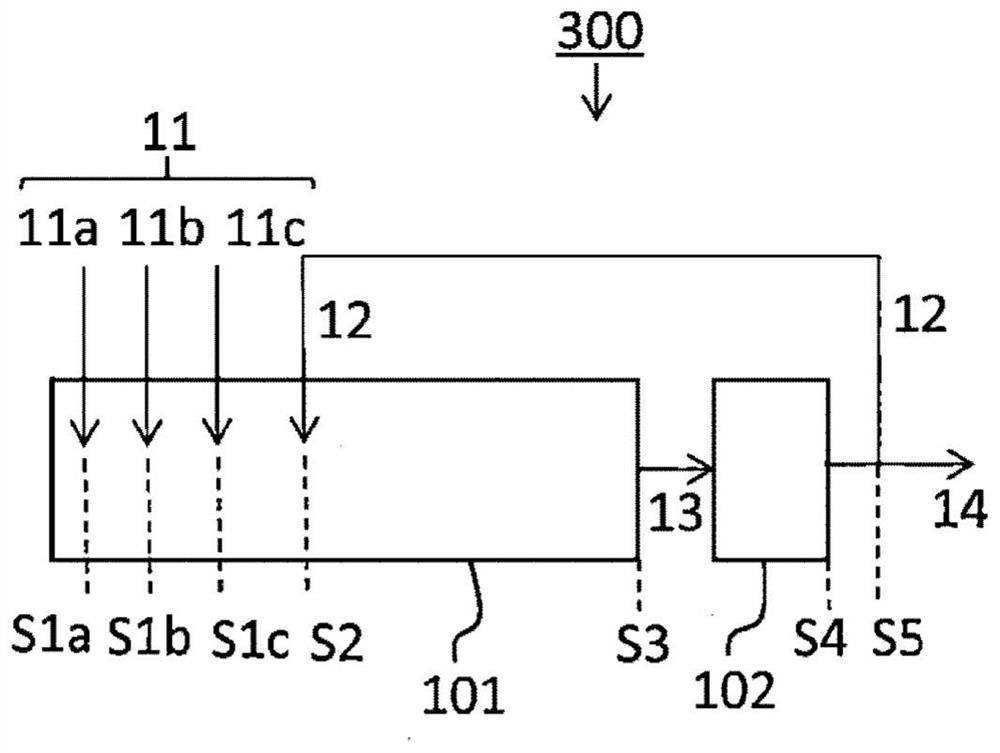

[0151] Figure 1 ~ 3 100, 200 is an explanatory process diagram of an example of a manufacturing method of a first embodiment of the resin molded body. Refer Figure 1 ~ 3 , 100,200,300 in the process, the feed material 11 101, or the main constituent component melt mixing unit (i.e. (A) the thermoplastic resin 11a, (B), and optionally the cellulose nanofiber additional component 11b 11c) and the auxiliary feed material 12 melted and mixed, the molten mixture generates 13 resin composition, molding the resin composition 13 in the forming unit 102, generates the resin molded body 14. Resin molded body 14 may have a pellet shape.

[0152]

[0153] 11 may be a main feed material comprising (A) a thermoplastic resin 11a, forms (B) and the cellulose nanofiber 11b 11c optional additional component of the mixture ( figure 1 and 2 11a, (B) cellulose nanofibers 11b, and 11c form an optional additional component in the main feed material 11), or as a main constituent component of the feed m...

no. 2 Embodiment approach

[0166] Figure 4 An example of a process 400 illustrating an example of a method of manufacturing a resin molded body according to a second embodiment. Refer Figure 4 In the process 400, the main supply material 41 and the auxiliary supply material 42 are melt mixed in the molten mixing portion 401, and the resin composition 43 as the molten mixture is formed, and the formation of the resin composition 43 is formed in the molding portion 402, and the resin molded body 44 is formed. . The resin molded body 44 can be a shape (pellets, etc.) for supplying to a further processing, or various product shapes described later.

[0167]

[0168] The main supply material 41 can comprise the first material 41a and the second material 41b. In one way, the first material 41a is a molten mixture. In one way, the first material 41a is a resin molded body 14 obtained by the first embodiment. In one way, the first material 41a is a molded body comprising 100 parts by mass (a) thermoplastic resin ...

Embodiment

[0191] The examples of the present invention will be further illustrated below, but the present invention is not limited by the examples. It should be noted that the primary measurement value of the material is determined by the following method.

[0192]

[0193] The resulting pellet-shaped molded body is formed into a multi-purpose test piece according to ISO294-1. For the resulting multi-purpose test piece, the tensile yield strength was determined according to ISO 527-1. For the forming sheet fractured before the yield, the maximum intensity is used.

[0194]

[0195] The resulting pellet-shaped molded body was used as a plate specified in JIS K7152-3 using an injection molding machine. For Examples 1 to 21, Comparative Examples 1 to 5, a plate of 60 mm × 60 mm × 2 mm was used, and a flat plate of 60 mm × 80 mm × 2 mm was used for Example 22, Comparative Examples 6, 7. For flat plate forming sheets, the shrinkage ratio is calculated based on the size of the resin flow direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com