Cobalt-free high-nickel positive electrode material and preparation method thereof

A cathode material, high nickel technology, applied in battery electrodes, structural parts, electrical components, etc., can solve the problems of cycle stability to be further improved, uneven coating oxide, etc., to avoid cycle performance loss, good high and low temperature Cycle performance, high capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

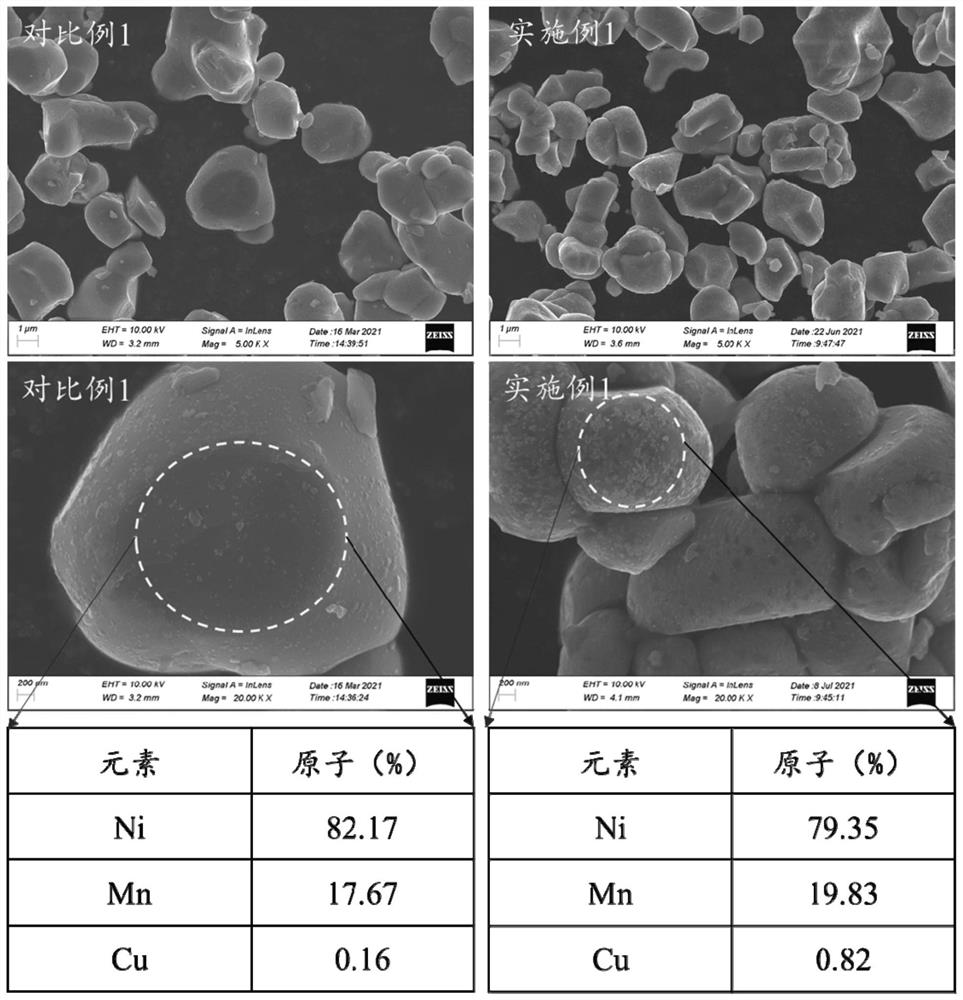

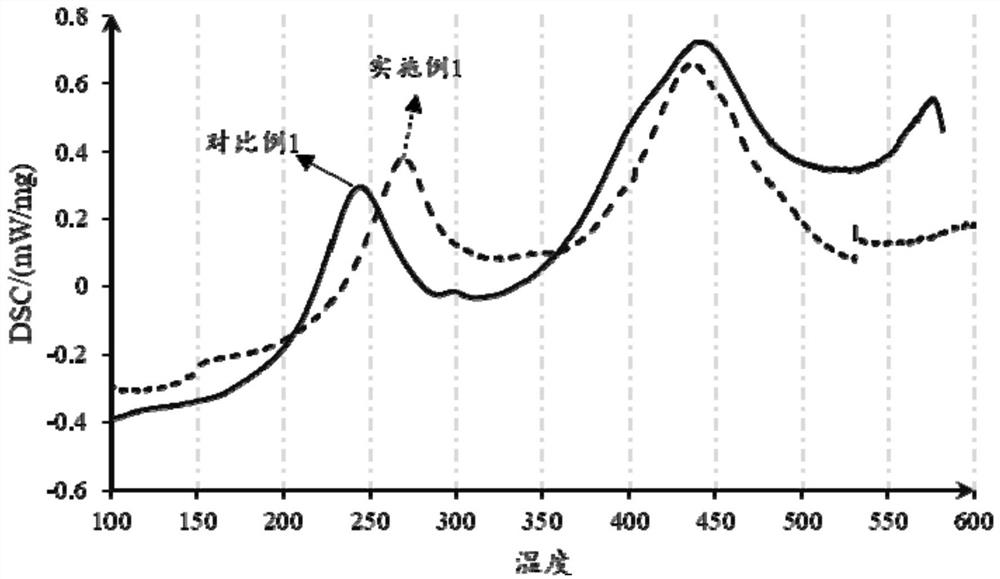

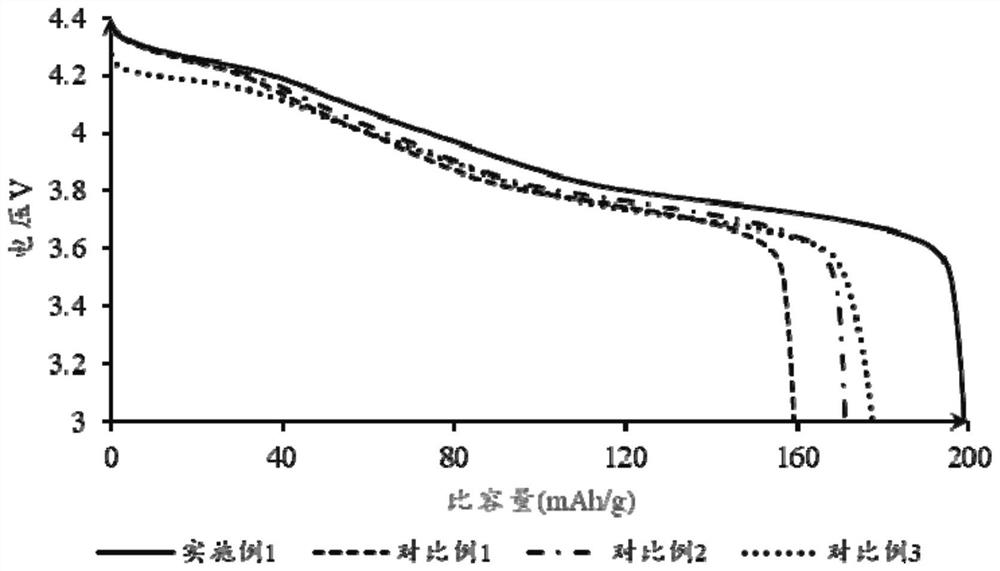

Embodiment 1

[0042] This embodiment provides a cobalt-free high-nickel positive electrode material, the specific preparation method is as follows:

[0043] The electroless plating solution of present embodiment configuration 1L, gets 78gCuSO 4 ·5H 2 O,93gCu(NO 3 ) 2 ·6H 2 Dissolve O in deionized water, add 20g sodium citrate and 25g ammonium sulfate, and prepare an electroless plating solution with copper ion concentration of 40g / L, sodium citrate concentration of 20g / L, and ammonium sulfate concentration of 25g / L, using ammonia water Adjust the pH to 10, adjust the temperature of the water bath to 30°C, slowly add 50g of cobalt-free high-nickel cathode material substrate into the reaction vessel at a rotation speed of 300rpm, control the feeding rate to 20g / min, and filter the obtained reaction product after 4 hours of reaction , washed by centrifugation for 3 times, and fully dried in a 120°C blast drying oven to obtain an electroless plating coating material.

[0044] Calcination: ...

Embodiment 2

[0048] This embodiment provides a cobalt-free high-nickel positive electrode material, the specific preparation method is as follows:

[0049] The electroless plating solution of present embodiment configuration 1L, gets 186gCu (NO 3 ) 2 ·6H 2 Dissolve O in deionized water, add 20g sodium citrate and 25g ammonium sulfate, and prepare an electroless plating solution with copper ion concentration of 40g / L, sodium citrate concentration of 20g / L, and ammonium sulfate concentration of 25g / L, using ammonia water Adjust the pH to 10, adjust the temperature of the water bath to 30°C, and slowly add 50 g of cobalt-free high-nickel cathode material substrate into the reaction vessel at a speed of 300 rpm, control the feeding rate to 20 g / min, and react for 4 hours. Filter, centrifuge and wash 3 times, and fully dry in a blast drying oven at 120°C to obtain an electroless plating coating material.

[0050] Calcination: calcining the obtained electroless plating cladding material; the ...

Embodiment 3

[0052] This embodiment provides a cobalt-free high-nickel positive electrode material, the specific preparation method is as follows:

[0053] The electroless plating solution of present embodiment configuration 1L, gets 107gCuCl 2 2H 2 Dissolve O in deionized water, add 20g sodium citrate and 25g ammonium sulfate, and prepare an electroless plating solution with copper ion concentration of 40g / L, sodium citrate concentration of 20g / L, and ammonium sulfate concentration of 25g / L, using ammonia water Adjust the pH to 10, adjust the temperature of the water bath to 30°C, and slowly add 50g of cobalt-free and high-nickel cathode material into the reaction vessel at a speed of 300rpm, and control the feeding rate to 20g / min. After 4 hours of reaction, filter the obtained reaction product , washed by centrifugation for 3 times, and fully dried in a 120°C blast drying oven to obtain an electroless plating coating material.

[0054] Calcination: calcining the obtained electroless p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com