In-situ deposited plate concrete roof with prefabricated combined hollow steel bar structure

A concrete slab and reinforced concrete technology, which is applied to floors, building components, buildings, etc., can solve the problems of large leakage of cast-in-place concrete, poor earthquake resistance, and self-heaviness, and achieve the advantages of small formwork loss, fast construction progress, and increased height Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

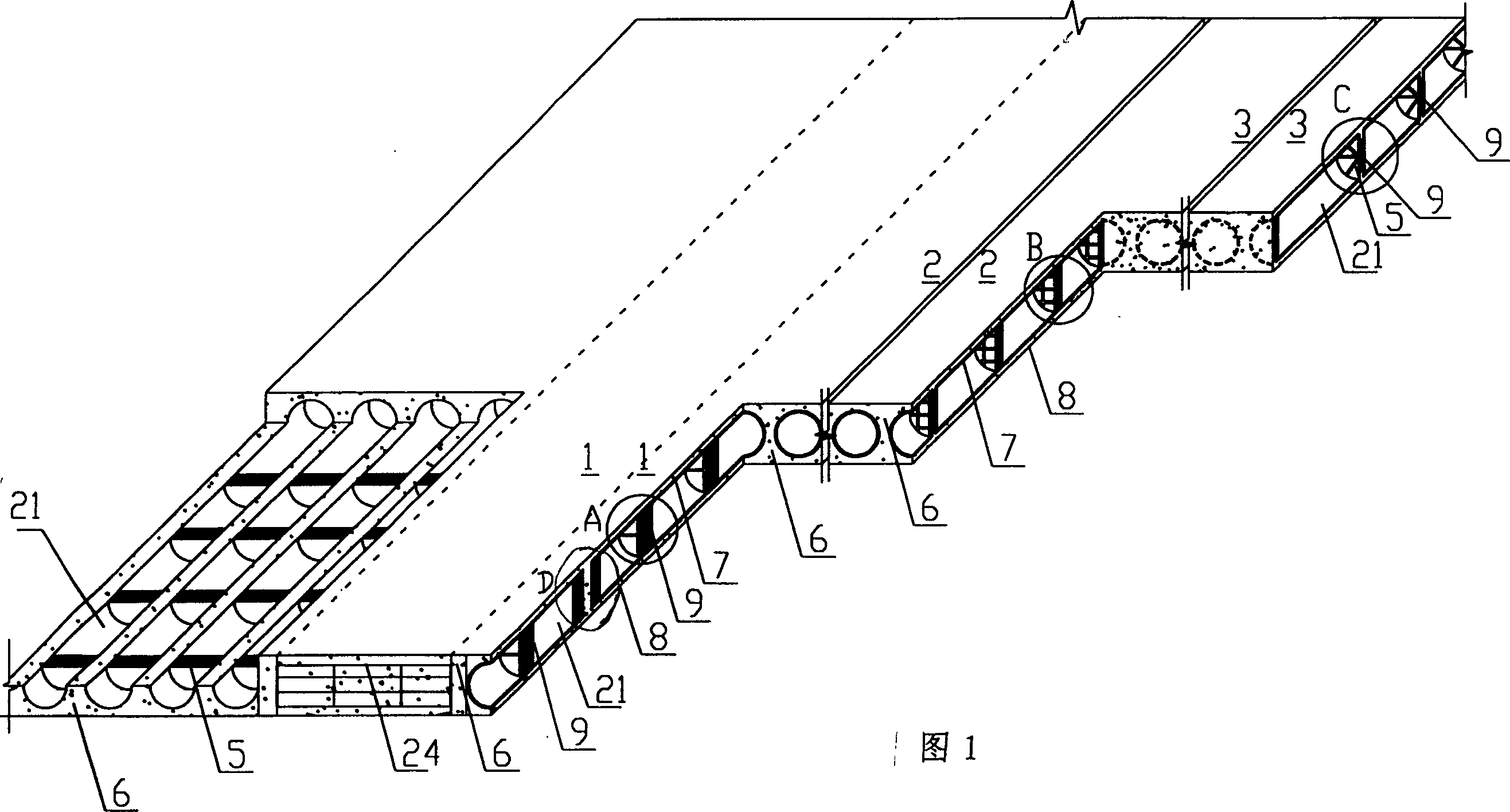

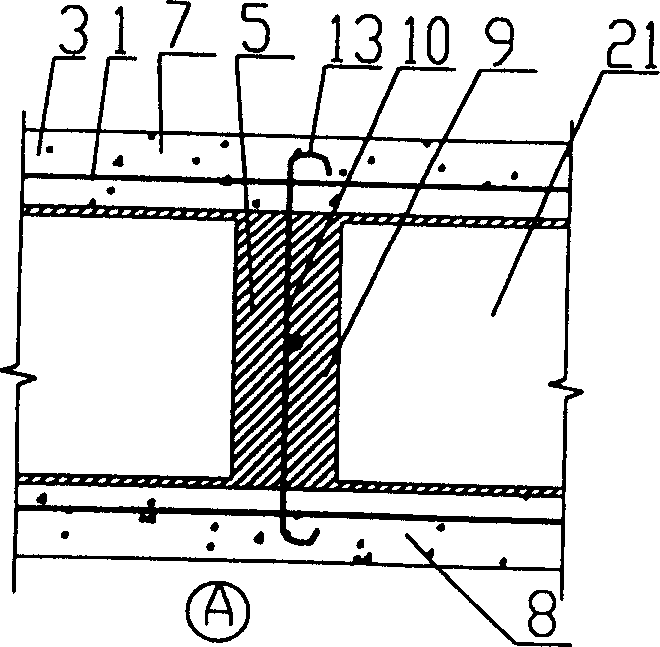

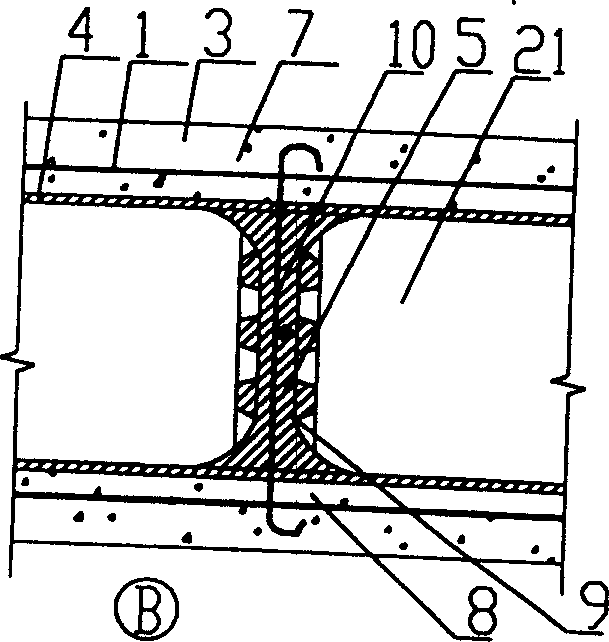

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The present invention is shown in accompanying drawing 1-8, and it is made up of concealed beam 24 between wall columns, main stress reinforcement bar 1 in the plate, structural reinforcement bar 2, concrete 3, the hollow tube member 4 preset in the reinforcement bar, the hollow tube The cross-sectional shape of the component 4 can be circular, square or other irregular shapes, and the hidden beam 24 between the wall columns is equal to the thickness of the hollow plate. It is characterized in that the hollow tube component 4 is a prefabricated bidirectional hollow tube component 4 with transverse stiffeners 5, The transverse stiffeners 5 in the two-way hollow tubular member 4 are combined with the cast-in-place reinforced concrete longitudinal ribs 6 to form a two-way concealed rib network where the prefabricated transverse stiffeners 5 and the cast-in-pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com