Impurity detection method for pimobendan soft chewing dosage form

A technology of pimobendan and a detection method, applied in the field of impurity detection, can solve problems such as poor solubility, baseline fluctuation, poor compatibility, etc., and achieve the effects of prolonging service life, increasing durability, and increasing durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Adjusting the ratio of chromatographic column and mobile phase on the basis of EP method

[0063] Chromatographic conditions: Agilent C18 chromatographic column (4.6*250mm, 5μm); mobile phase A: 3g / L potassium dihydrogen phosphate solution (phosphoric acid to adjust the pH to 2.5), mobile phase B: acetonitrile; detection wavelength: 290nm, flow rate 1.0ml / min; Column temperature: 45°C;

[0064] time (min) mobile phase A mobile phase B 0.00 85 15 10.00 80 20 30.00 40 60 30.01 85 15 40.00 85 15

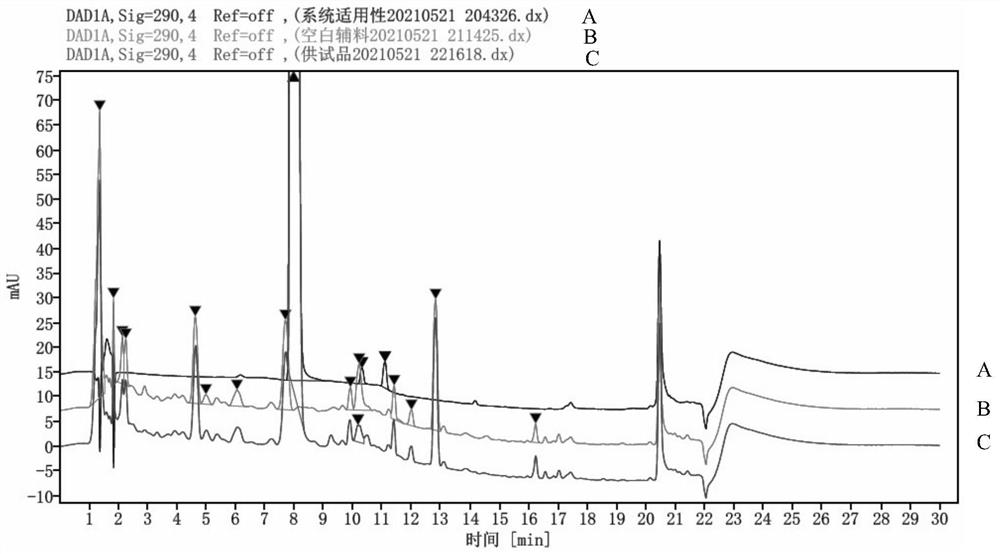

[0065] Test results such as image 3 As shown, under the conditions of Example 1, the auxiliary materials interfered with the main peak and the detection of impurities at 13min and 17min respectively.

Embodiment 2

[0067] Chromatographic conditions: on the basis of Example 1, the pH of the mobile phase A was adjusted to pH 3.0, and the chromatographic column was Agilent C18 (4.6*150mm, 4 μm).

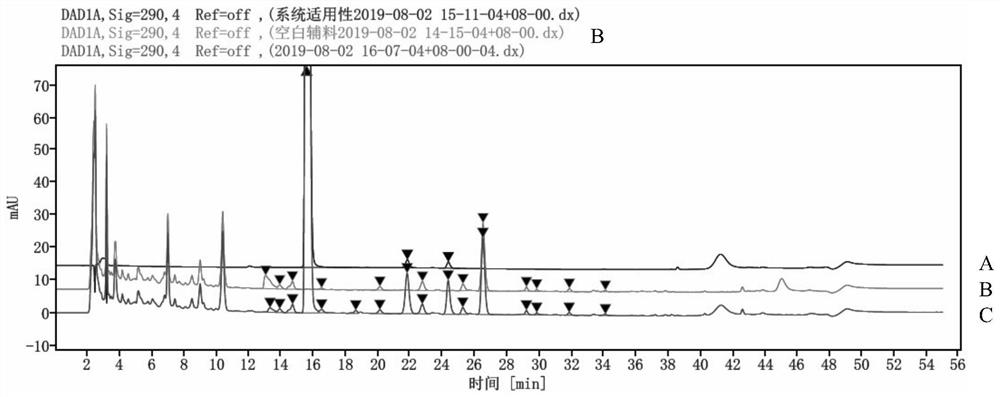

[0068] Its test results are as Figure 4 As shown, under the conditions of Example 2, the peak eruption time of the main peak is about 15 minutes, but the auxiliary materials still interfere with the detection of the main peak and impurities.

Embodiment 3

[0070] Observe the experimental results by adjusting the mobile phase ratio

[0071] Chromatographic conditions: Agilent C18 column (4.6*150mm, 4μm), mobile phase A: 3g / L potassium dihydrogen phosphate solution (phosphoric acid to adjust pH to 3.0), mobile phase B: acetonitrile; detection wavelength: 290nm, flow rate 1.0ml / min, column temperature: 45°C

[0072] time (min) mobile phase A mobile phase B 0.00 85 15 10.00 80 20 20.00 70 30 40.00 40 60 40.01 85 15 50.00 85 15

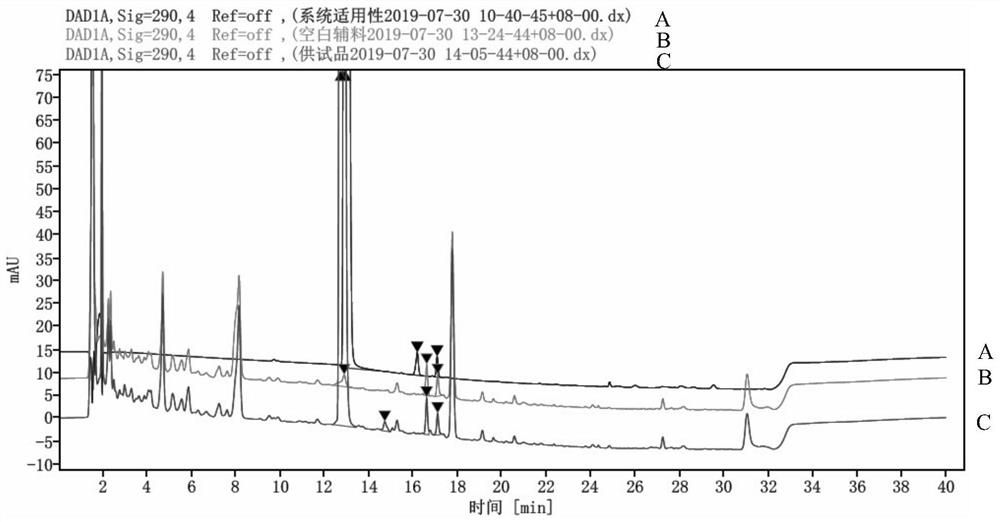

[0073] Its test results are as Figure 5 As shown, it can be seen that the gradient at 10-20min still needs to be improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com