Optical fiber FBG sensor and system for measuring pressure of high-energy pipeline of nuclear power device

A high-energy pipeline and measurement system technology, applied in the field of pipeline pressure measurement, can solve the problems of large volume, unreliable performance, and inability to achieve distributed measurement, and achieve the effect of small size, strong anti-electromagnetic interference ability, and saving layout space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

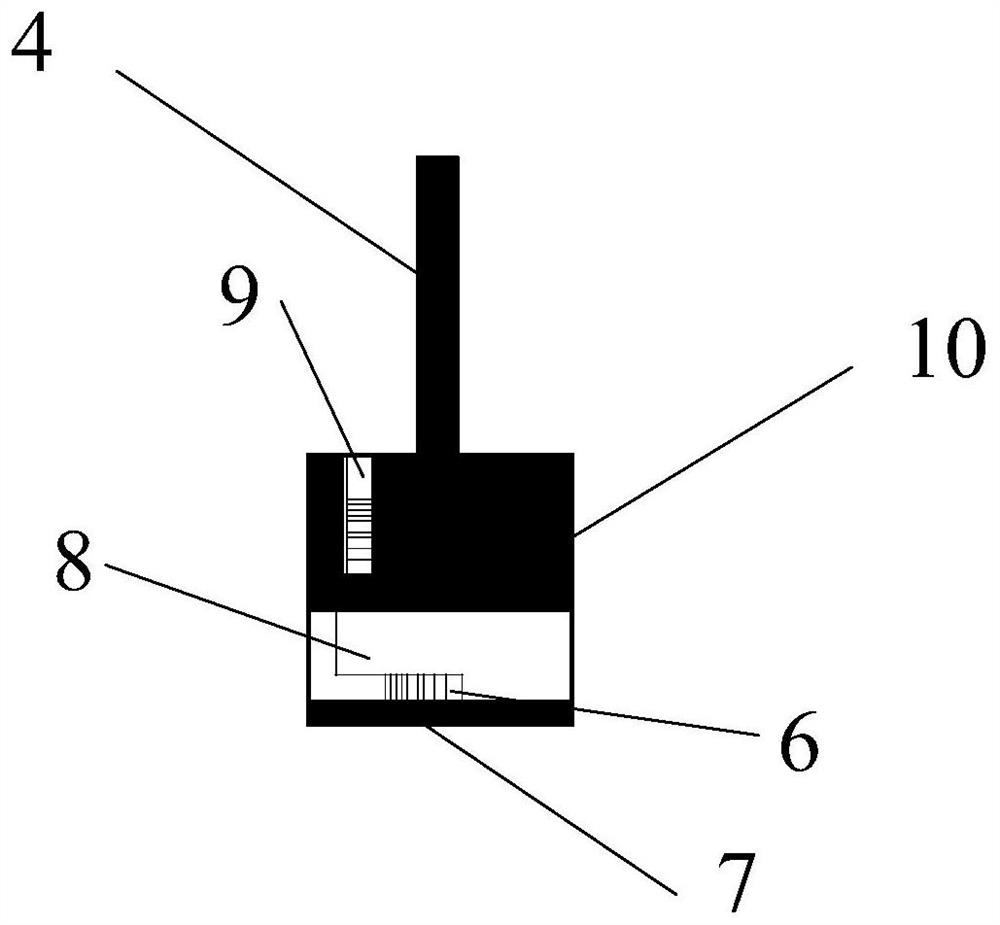

[0057] Such as Figure 1-Figure 2 As shown, the optical fiber FBG sensor used for pressure measurement of high-energy pipelines in nuclear power plants includes a diaphragm 7, a capsule 8, a sealing part 10 of the capsule, a pressure-sensitive FBG optical fiber 6 and a temperature-sensitive FBG optical fiber 9;

[0058] The diaphragm 7 and the bellows sealing portion 10 are respectively arranged at both ends of the bellows 8 for sealing the bellows 8;

[0059] The pressure-sensitive FBG optical fiber 6 is placed in the bellows 8 and arranged on the diaphragm 7, the temperature-sensitive FBG optical fiber 9 is embedded in the sealing part 10 of the bellows, the pressure-sensitive FBG optical fiber 6 and the temperature-sensitive FBG optical fiber 9 After passing through the sealing part 10 of the bellows, they merge to form the transmission optical cable 4 .

[0060] In the embodiment, the pressure-sensitive FBG optical fiber 6 and the temperature-sensitive FBG optical fiber 9...

Embodiment 2

[0066] Such as Figure 1-Figure 2 As shown, a nuclear power plant high-energy pipeline pressure measurement system includes a sensor 3, a mechanical seal structure 2, a transmission optical cable 4 and a demodulator 5;

[0067] Described sensor 3 is the optical fiber FBG sensor described in embodiment 1;

[0068] The sensor 3 is installed on the side wall of the high-energy pipeline 1 through the mechanical seal structure 2, and the diaphragm 7 of the sensor 3 extends into the high-energy pipeline 1 to contact with the coolant medium;

[0069] The sensor 3 is electrically connected to the demodulator 5 through the transmission optical cable 4 .

[0070] In this embodiment; the connection mode between the mechanical seal structure 2 and the high-energy pipeline 1 is sealing thread and sealing welding, which can effectively ensure that the high-pressure medium will not flow from the position of the sensor 3 of the high-energy pipeline 1 when the nuclear power plant is running. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com