Long-connection seamless bridge and building integrated elevated station structure

A seamless bridge and station technology, applied in the field of concrete hinges, can solve problems such as inconvenience in construction and operation, damage to the integrity of the station structure, and increase in pier height, so as to facilitate construction and later operation and maintenance, improve the internal force of the station structure, and avoid easy aging aging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

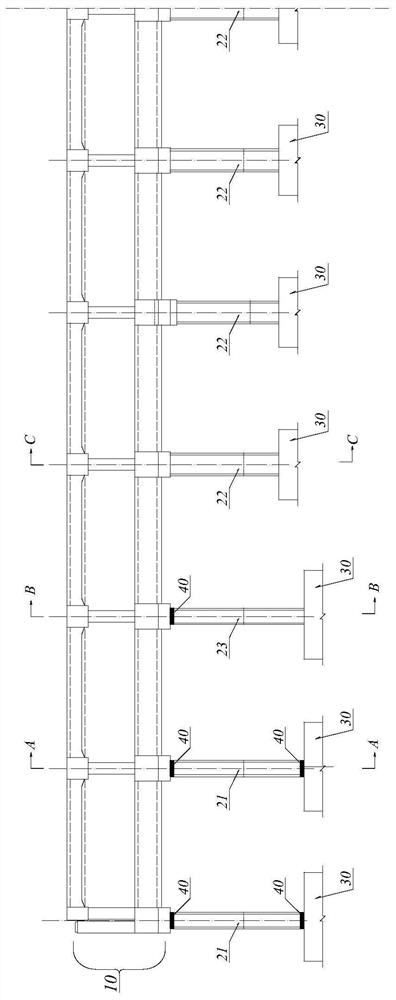

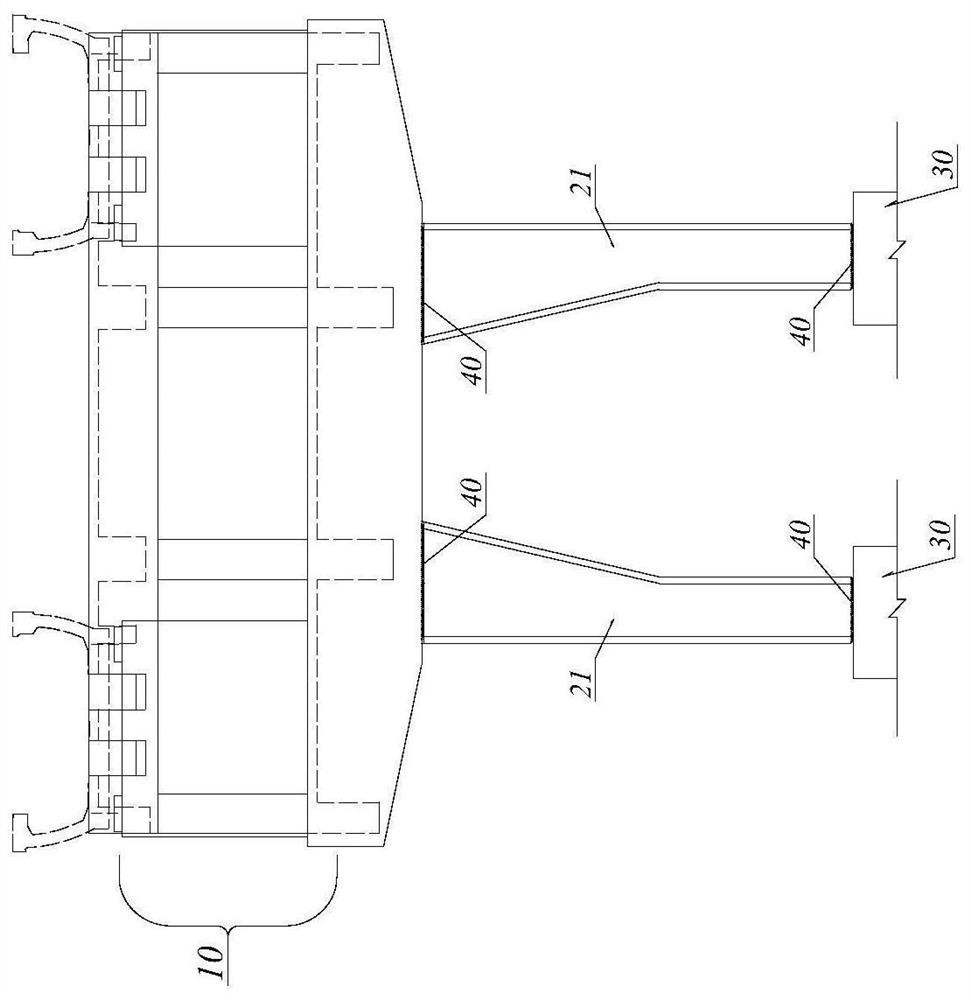

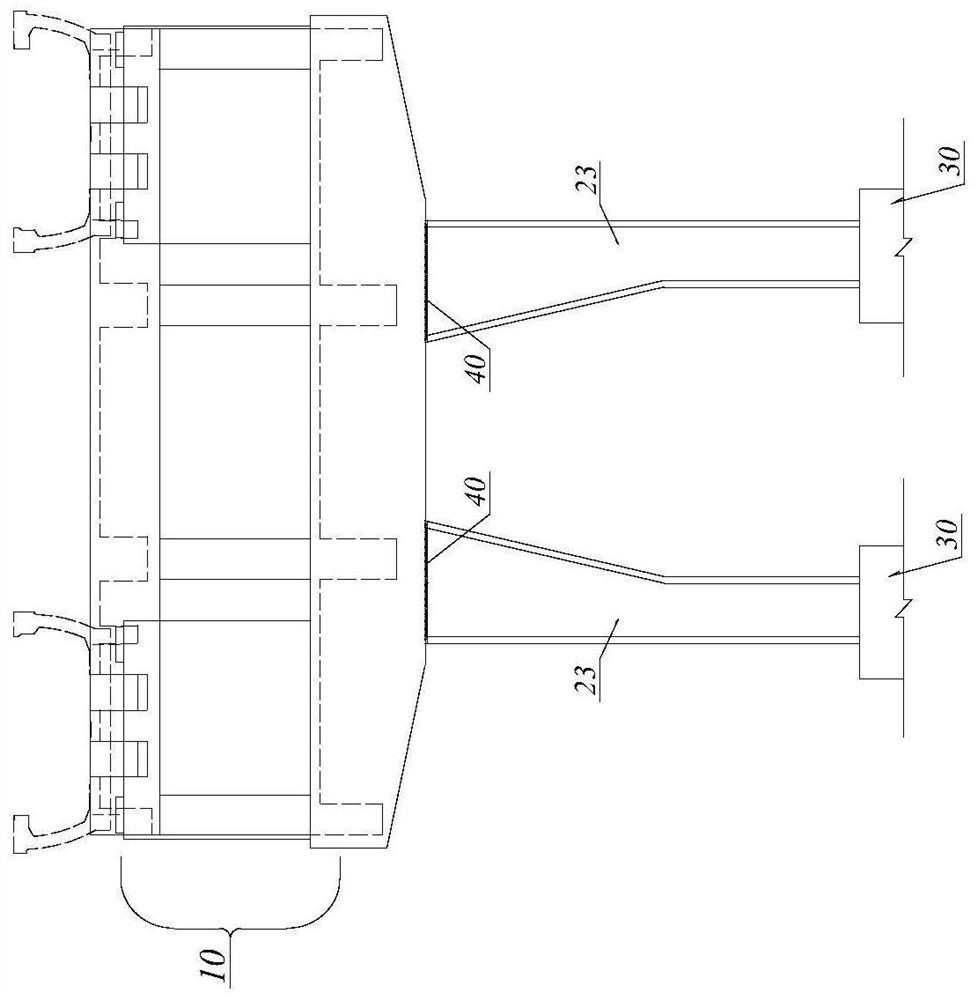

[0026] refer to figure 1 A long-connected seamless bridge of the present invention is built into an elevated station structure, comprising a station superstructure 10 and pier columns and caps 30 arranged at intervals along the line direction, and the upper and lower ends of each pier column are connected to the station superstructure 10 respectively. , and the corresponding caps 30 are connected, and the piers include flexible connection piers 21 , rigid connection piers 22 , and semi-rigid transition piers 23 . refer to figure 2 , the flexible connecting pier column 21 is arranged on the two longitudinal ends of the station superstructure 10, and its upper and lower ends respectively form a flexible connection with the station superstructure 10 and the corresponding bearing platform 30 through the concrete hinge 40, the station superstructure 10 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com