Prefabricated assembling bridge pier connecting device and construction method thereof

A connecting device and prefabricated assembly technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as complex process, weak reliability, and large engineering volume, and achieve the effects of simple construction process, guaranteed construction quality, and improved construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in combination with specific embodiments.

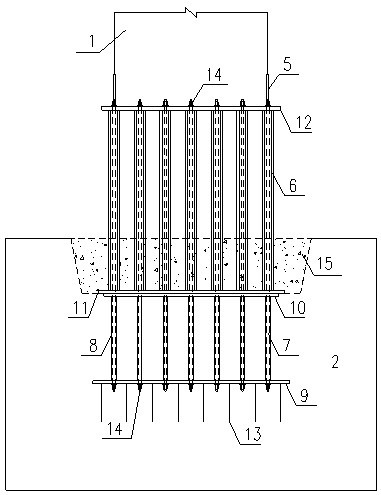

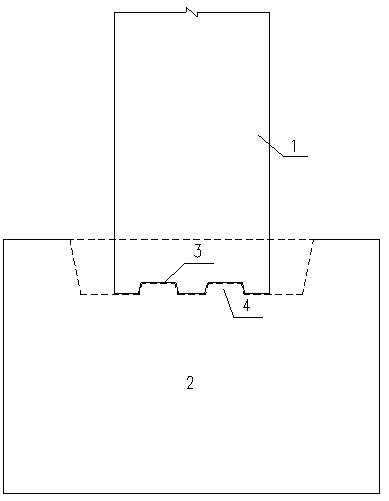

[0040] The prefabricated assembled bridge pier connection device involved in the present invention is a prefabricated assembled bridge pier construction process in the form of outsourcing steel plate + U rib + finished rolled screw steel connection, including the pier bottom connection device at the bottom of the prefabricated bridge pier 1 and the top of the cast-in-place cap 2 The prefabricated pier 1 and the cast-in-place cap 2 are connected and fixed through the upper and lower cooperation installation of the pier bottom connection device and the pre-embedded device for connecting the cap.

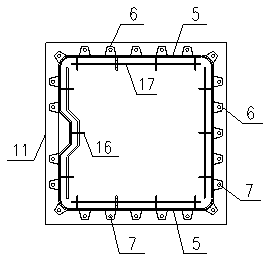

[0041] The connecting device at the bottom of the pier includes an outsourcing steel plate 5 , an upper bearing steel plate 12 , a U-shaped stiffener 6 and a steel plate 11 at the bottom of the pier. The outsourcing steel plate 5 is arranged on the outer periphery of the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com