Lifting equipment and method of box girder integral steel reinforcement framework

A technology of steel skeleton and hoisting equipment, which is used in bridge construction, bridges, transportation and packaging to achieve the effect of improving the speed of bridge construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings.

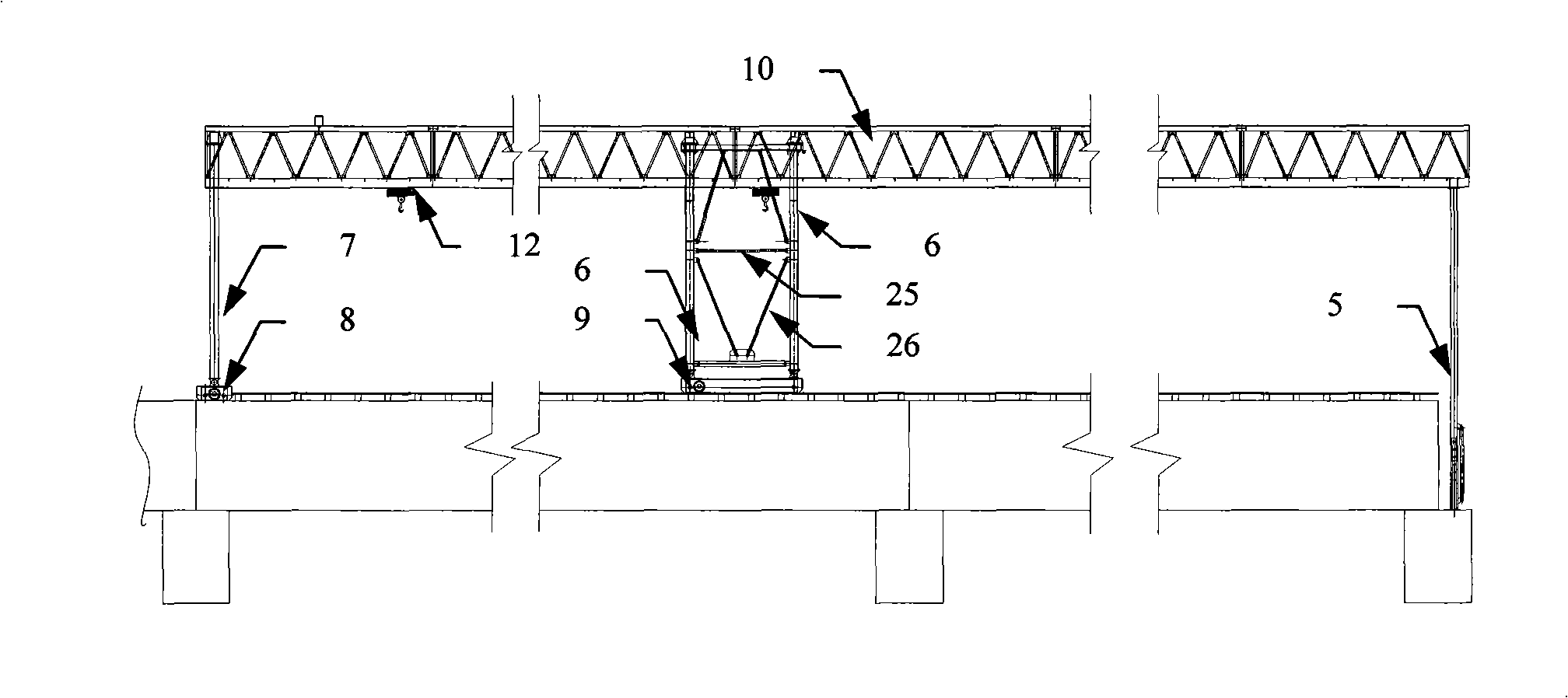

[0037] image 3 It is a structural schematic diagram of the hoisting equipment of the box girder integral steel skeleton described in the present invention, said hoisting equipment includes two parallel main beams a10 and main beam b11 of truss structure, and one end of main beam a10 and main beam b11 is connected A front outrigger 5 is connected, the other ends of the main beam a10 and the main beam b11 are connected with a rear outrigger 7, the middle part of the main beam a10 and the main beam b11 is connected with at least one middle outrigger 6, the main beam a10 and the main beam The b11 is provided with at least two electric hoists 12 that can move forward and backward along the main beam, the bottom of the rear leg 7 is provided with a rear leg wheel box 8 with a drive wheel 19, and the bottom of the middle leg 6 is provided with a drive wheel In the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com