Steel sleeve prefabricated assembly type pier with shear nails

A technology of prefabricated assembly and steel sleeves, which is applied in the direction of erecting/assembling bridges, bridges, bridge parts, etc., can solve problems such as damage and peeling, and achieve the effects of reducing workload, small environmental impact, and saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

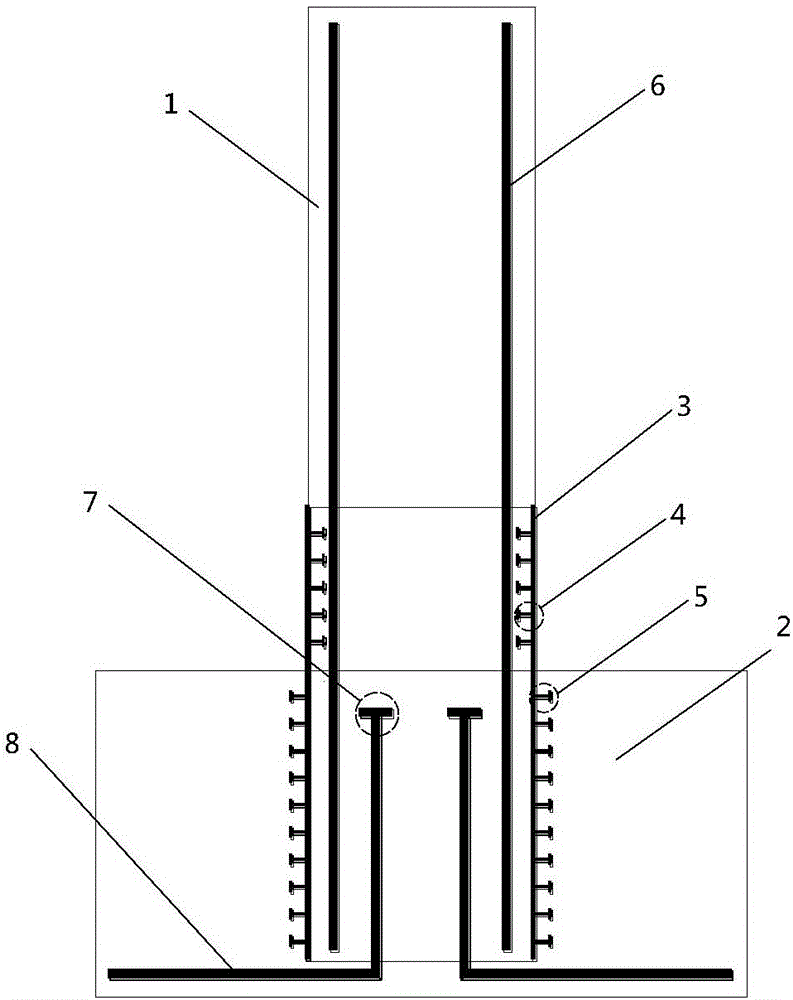

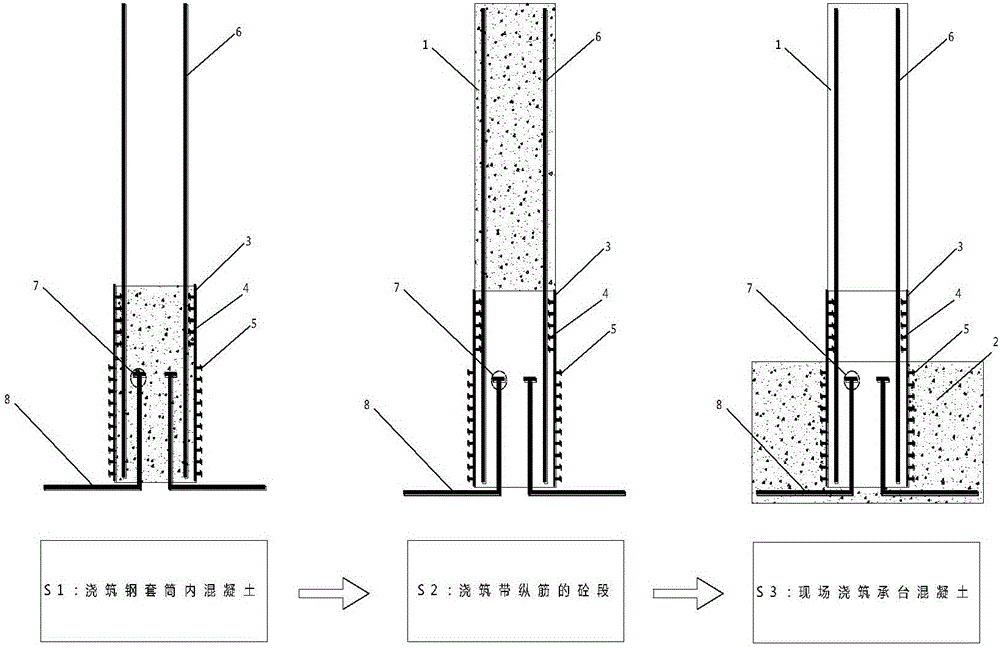

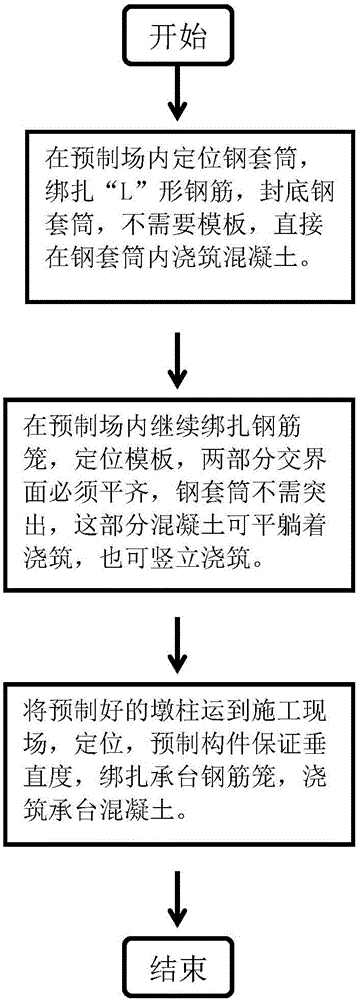

[0035] See figure 1 , the prefabricated assembled bridge pier with steel sleeves with shear nails provided in this embodiment includes caps 2 and pier columns 1, and steel sleeves 3 with shear nails connect the caps 2 and the pier columns 1, A part of the steel sleeve 3 is located in the cap 2, and the other part is connected to the pier 1, and the shear stud 5 of the steel sleeve part in the cap 2 is set on the steel sleeve 3 outside, the shear stud 4 of the steel sleeve part connected to the pier column 1 is arranged inside the steel sleeve 3 . The pier column 1 is also pre-embedded with pier body pre-embedded longitudinal reinforcement 6, and the pier body pre-embedded longitudinal reinforcement 6 is inserted into the steel sleeve part of the cap 2, and the cap 2 is provided with " L"-shaped steel bar 8, a section of the "L"-shaped steel bar 8 with pier thickness 7 is arranged inside the pre-embedded longitudinal reinforcement 6 of the pier body and poured together with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com