Medium-long rib prefabricated bottom plate hoisting structure and construction method thereof

A technology of medium-long ribs and base plates, which is applied to truss structures, floor slabs, building components, etc., can solve the problems of lack of complete sets of construction methods for prefabricated base plates with ribs, and achieve the effects of increasing height, improving bending resistance, and avoiding buckling deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

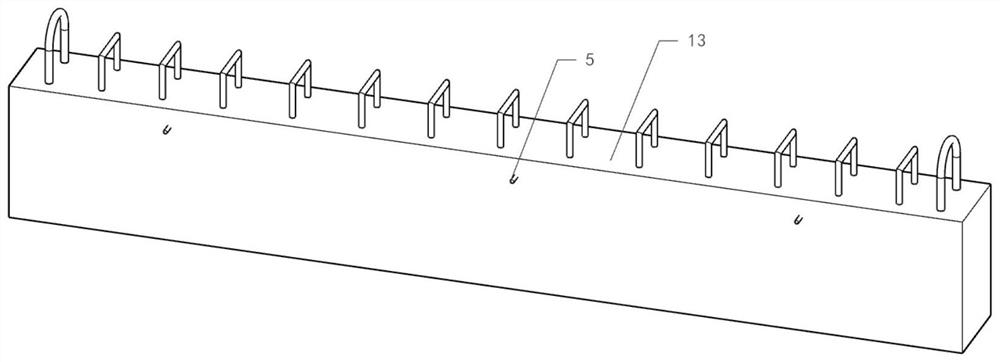

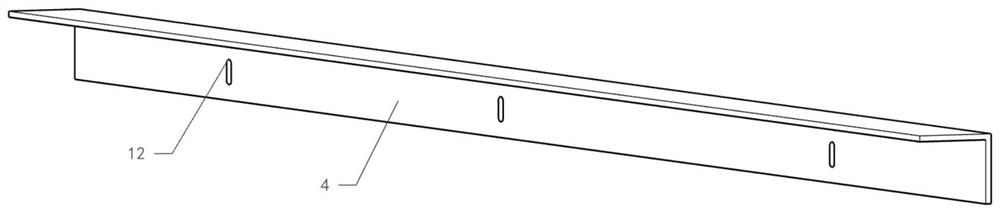

[0054] This embodiment provides a medium-long-rib prefabricated floor hoisting structure, which includes structural beams 13 arranged side by side. The edge of the detachable angle steel 4 is provided with a side end surface of the detachable angle steel 4 attached to the end surface of the structural beam 13, and the other side end surface of the detachable angle steel 4 is attached to the middle and long rib prefabricated floor 2 On the lower end surface, the detachable angle steel 4 is provided with a top-tightening structure for closely fitting the detachable angle steel 4 with the prefabricated bottom plate 2 with medium and long ribs, and the upper end surface of the prefabricated bottom plate with medium and long ribs 2 is provided with a hoisting structure.

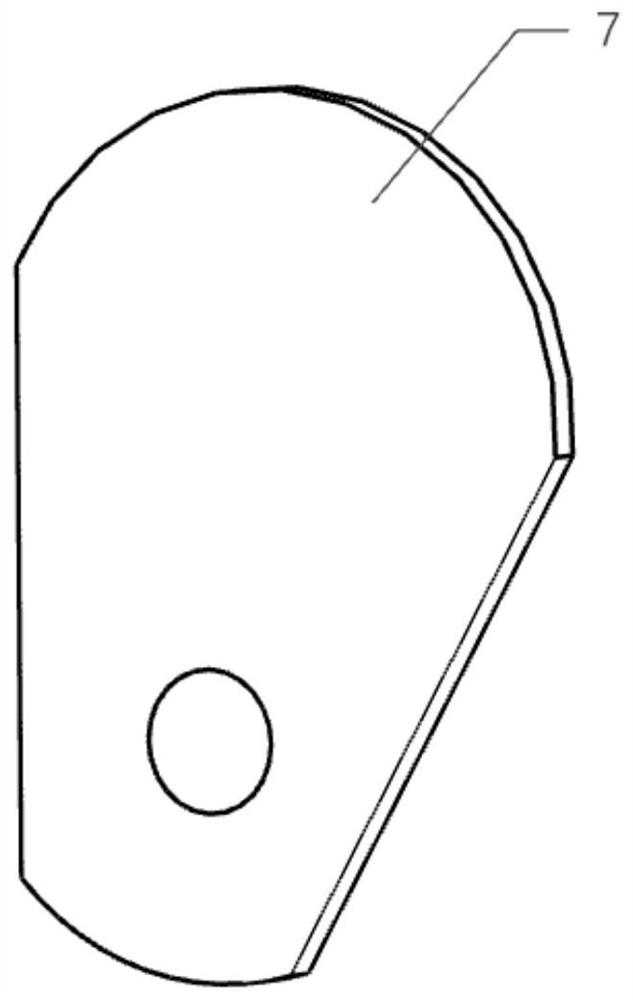

[0055] Specifically combined in this embodiment, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 As shown, the prefabricated fl...

Embodiment 2

[0068] This embodiment provides another medium and long rib prefabricated floor lifting structure. The medium and long rib prefabricated floor 2 in Embodiment 1 is replaced by a rib key combination prefabricated floor 14, and two ends of the medium and long rib 21 are respectively provided with The shear key 22, the suspension ring is arranged between the middle long rib 21 and the shear key 22, and the I-shaped piece 15 is arranged on the middle long rib 21 and the shear key 22, specifically ,Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, in the construction method corresponding to the structure:

[0069] In step 3 of the above-mentioned embodiment 1, the suspension ring 1 is placed at a predetermined position between the rib keys of the prefabricated bottom plate 14 rib keys before the concrete is poured;

[0070] In step 4 of the above-mentioned embodiment 1, concrete is pou...

Embodiment 3

[0076] This embodiment provides another medium-long-rib prefabricated floor hoisting structure. The medium-long-rib prefabricated floor 2 in Embodiment 1 is replaced by a ribbed steel truss prefabricated floor 16, and the lifting ring 1 is canceled. The medium-long-rib prefabricated floor 2 includes a plate structure, a plurality of steel bar trusses 23 are distributed in parallel at equal intervals on the upper end of the plate body structure, and middle and long ribs 21 are arranged between two adjacent steel bar trusses 23, so that the steel bar trusses 23 and the The middle and long ribs 21 are arranged alternately, and a tubular piece is pierced under the steel bar truss 23, and a suspension rope is sheathed on the tubular piece. Specifically, as figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Figure 7 , Figure 10 , Figure 14 , Figure 15 , Figure 16 Shown:

[0077]Step 3 of the above-mentioned embodiment 1 is cancelled, and step 4 is carried out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com