Polymer foaming microspheres as well as preparation method and application thereof

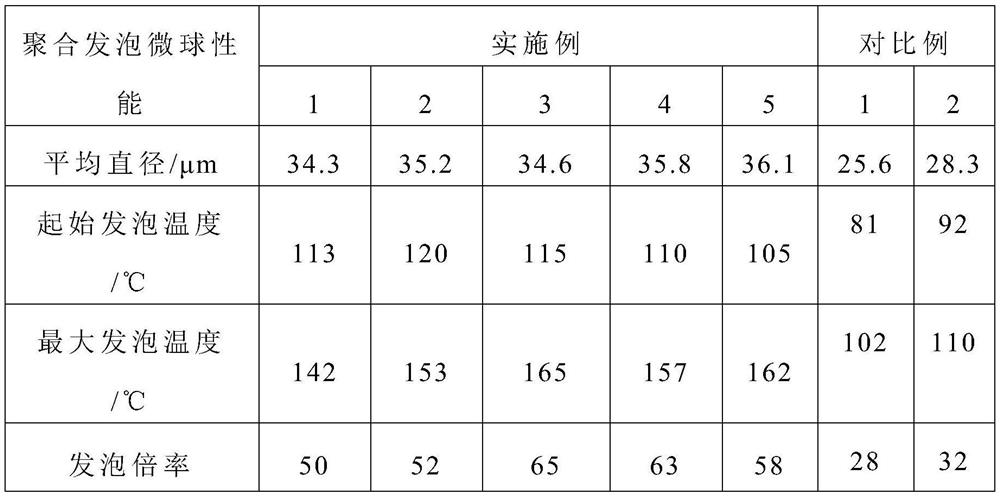

A technology of foaming microspheres and polymers, applied in the field of foaming materials, to achieve the effects of improving temperature resistance, improving dispersion, and increasing foaming ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

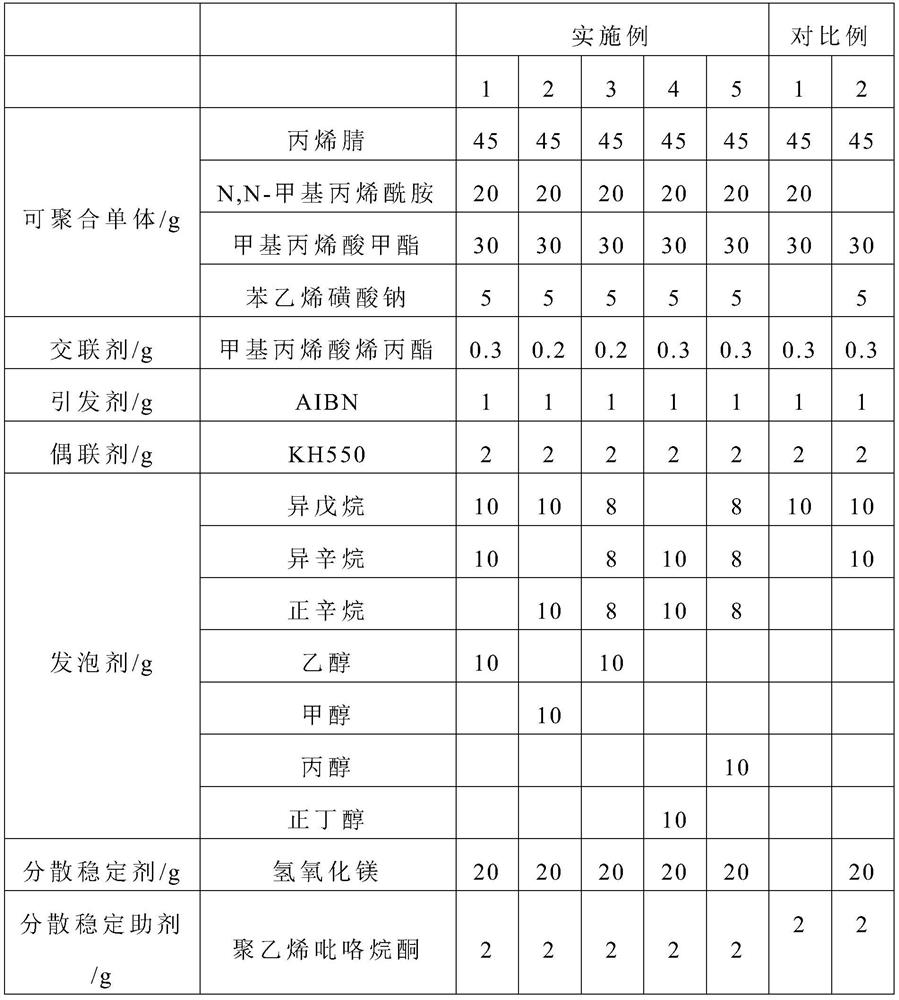

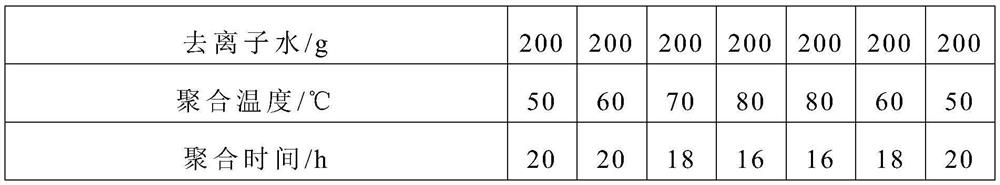

Examples

preparation example Construction

[0025] According to the present invention, a method for preparing polymer foamed microspheres is provided, the method comprising: preparing an oil phase mixture; preparing an aqueous dispersion medium, dispersing the oil phase mixture in the aqueous dispersion medium for suspension polymerization, and preparing the polymerized foamed microspheres.

[0026] According to the invention, the oil phase mixture comprises polymerizable monomers and a crosslinking agent.

[0027] According to the present invention, polymerizable monomers include nitrile-based monomers, carboxyl-containing monomers, vinyl halide-based monomers, (meth)acrylate-based monomers, acrylamide-based monomers, maleamide-based monomers, non- One or more of saturated monoolefin monomers, vinyl ketone monomers, N-vinyl monomers, vinyl naphthalene salts, etc.

[0028] According to the present invention, nitrile monomers such as acrylonitrile, methacrylonitrile, 2-methyl-2-propenyl, 2-chloroacrylonitrile, 2-ethoxya...

Embodiment approach

[0036] According to a preferred embodiment of the present invention, the polymerizable monomer comprises the following raw material components in weight ratio:

[0037] Nitrile monomer 40-90 parts by weight, preferably 45-85 parts by weight

[0038] Acrylamide monomer 1-30 parts by weight, preferably 5-25 parts by weight

[0039] The (meth)acrylate monomer is 5 to 40 parts by weight, preferably 10 to 30 parts by weight.

[0040] The present inventors found that the polymerizable monomer adopts nitrile monomer, (meth)acrylate monomer and acrylamide monomer to obtain higher foaming initiation temperature, and the obtained polymer foamed microsphere has High heat resistance and gas barrier properties.

[0041] According to a preferred embodiment of the present invention, the polymerizable monomers include acrylonitrile, methyl methacrylate, N,N-dimethylacrylamide.

[0042] According to the present invention, polymerizable monomers also include carboxyl-containing monomers, and...

Embodiment 1

[0123] 45g of acrylonitrile, 25g of N,N-methacrylamide, 30g of methyl methacrylate, 5g of sodium styrene sulfonate, 0.3g of allyl methacrylate, 10g of isopentane, 10g of isooctane, 10g of ethanol, 2g KH550 and 1g AIBN are mixed to obtain an oil phase mixture;

[0124] 200g of deionized water, 20g of magnesium hydroxide and 2g of polyvinylpyrrolidone were mixed, and then the pH was adjusted to 3.0 as an aqueous dispersion medium;

[0125] Mix the oil phase mixture and the aqueous dispersion medium, and disperse for 3 minutes at a speed of 10,000 rpm with a homomixer to obtain a suspension, then place the suspension in a polymerization reactor, replace it with nitrogen, and set the pressure of the polymerization reactor The temperature is 0.8MPa, the polymerization reaction temperature is 60°C, and the polymerization reaction time is 20h. Polymer foamed microspheres are obtained after polymerization.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com