Metal corrosion inhibitor and preparation method thereof

A technology of metal corrosion inhibitors and solvents, applied in the field of metal corrosion inhibitors and their preparation, can solve the problems of high difficulty, high cost of metal corrosion inhibitors, and non-environmental protection, and achieve simple operation, short synthesis steps, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

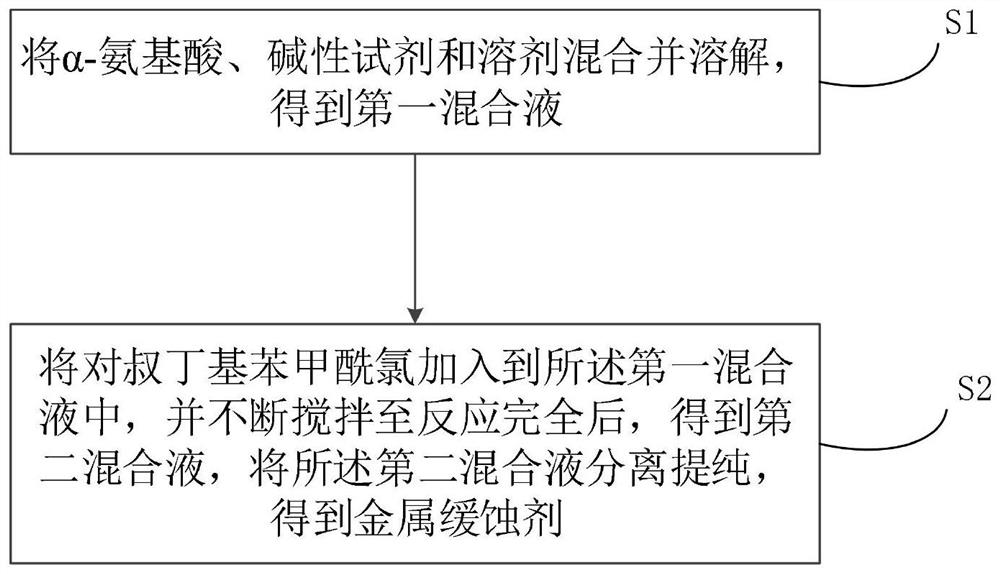

[0032] combine figure 1 As shown, the embodiment of the present invention provides a kind of preparation method of metal corrosion inhibitor, comprises the following steps:

[0033] Step S1: Mix and dissolve the α-amino acid, basic reagent and solvent to obtain the first mixed solution; the basic reagent includes hydroxides of alkali metal elements such as sodium hydroxide and potassium hydroxide, and other substances that can participate in the reaction Alkaline reagent.

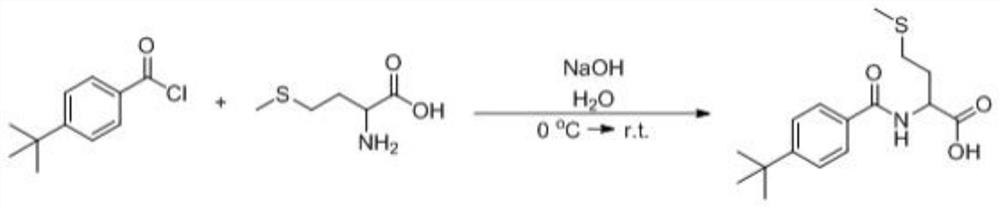

[0034] Step S2: Slowly add p-tert-butylbenzoyl chloride into the first mixed solution, and keep stirring until the reaction is complete, and the reaction temperature is naturally returned to room temperature from -10°C to 5°C to obtain the second mixed solution. The second mixed liquid is separated and purified to obtain a metal corrosion inhibitor. Wherein p-tert-butylbenzoyl chloride slowly joins in the first mixed solution that contains α-amino acid, helps to control reaction temperature, can release h...

Embodiment 1

[0057] The preparation method of the present embodiment metal corrosion inhibitor is carried out according to the following steps:

[0058] S1: Take 1.49g methionine (Meth) with a balance and add it to a 50mL round-bottomed flask, take 0.8g sodium hydroxide with a balance, add it to the round-bottomed flask, and add 5mL deionized water to dissolve it. The round bottom flask was placed in an ice water bath.

[0059] S2: Take 1.81 mL of p-tert-butylbenzoyl chloride with a syringe, slowly inject it into the round bottom flask, keep stirring during the injection process, keep stirring for 6 hours after the injection is completed, and the temperature naturally returns from -10 ° C to room temperature during the reaction process , after the reaction is over, add excess hydrochloric acid to quench the reaction, then use ethyl acetate to extract, after the extraction is completed, the metal corrosion inhibitor is separated by column chromatography.

[0060] The present embodiment ado...

Embodiment 2

[0068] The difference between this example and Example 1 is that the preparation method of the metal corrosion inhibitor in this example uses cysteine (Cys) instead of methionine (Meth) as the reaction raw material.

[0069] The preparation method of the present embodiment metal corrosion inhibitor is carried out according to the following steps:

[0070] S1: Weigh 0.61g cysteine (Cys) with a balance and add it to a 50mL round bottom flask, take 0.4g sodium hydroxide with a balance, add it to the round bottom flask, and add 5mL deionized water to dissolve it. The round bottom flask was placed in an ice water bath.

[0071] S2: Use a syringe to draw 0.98 mL of p-tert-butylbenzoyl chloride, slowly inject it into the round bottom flask, keep stirring during the injection process, keep stirring for 24 hours after the injection is completed, and the temperature naturally returns from 5 ° C to room temperature during the reaction process. After the reaction is finished, excess ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com