Graphene-rare earth gadolinium co-doped Ti/SnO2-Sb composite electrode and preparation method thereof

A composite electrode and graphene technology, applied in the field of electrocatalysis, can solve problems such as low toughness, poor conductivity, and short service life, and achieve the effects of good stability, improved service life, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

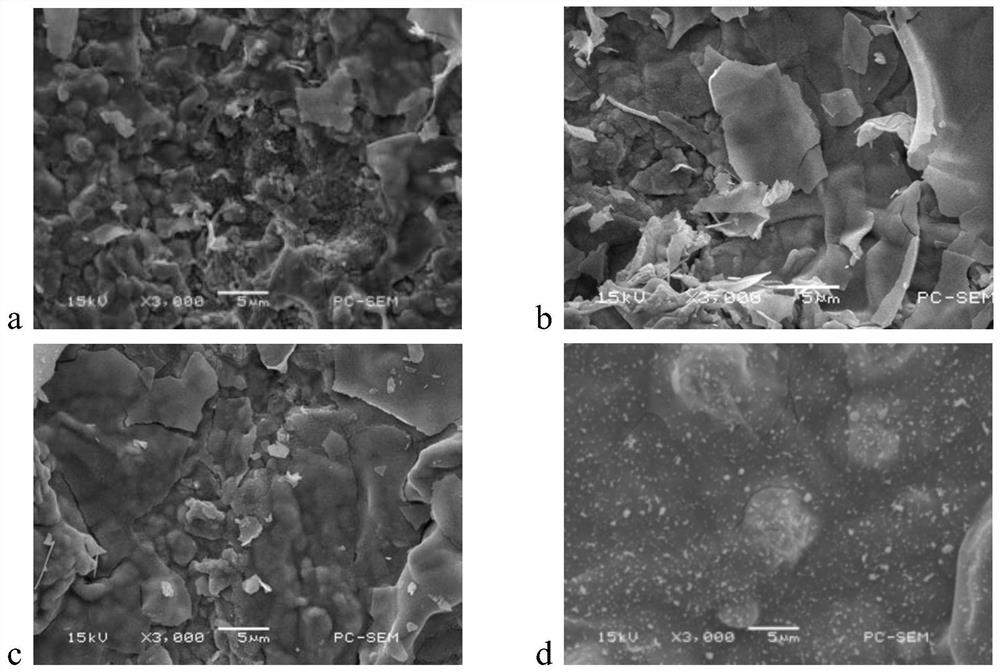

Embodiment 1

[0031] (1) First use a linear cutter to cut a titanium plate having a plurality of sizes of 50 mm × 20 mm (also known as the titanium substrate) in this application, first using 200 megadownloadtebiz. The sandpaper is polished to make it silver white metal gloss. Then, 50 mm × 20 mm titanium plate was carried out in a KQ-400 kDe type high power CNC ultrasonic cleaner, and the ultrasonic power was 450W, the cleaning time was 15-20 min, continued to wash the residual dirt and impurities with deionized water, and complete the titanium sheet Physical treatment. Then, the physical treatment was placed in a sodium hydroxide solution having a mass fraction of 40%, and the constant temperature was kept at a temperature of 80 ° C for 2 h, and after removal, washed with deionized water, and alkali washing. Then, the titanium sheet after washing is completely immersed in 15% oxic acid solution, and the water bath is 95 ° C, and the acid etched is heated. When the cooling is added, then the c...

Embodiment 2

[0035](1) First use the linear cutter to cut the titanium plate of 300 mm × 300 mm to a titanium plate having a plurality of sizes of 50 mm × 20 mm, first using 200 mesh crude sandpaper, and then use the 800 destination fine sandpaper to polish, so silver white metal. luster. Then, 50 mm × 20 mM titanium plate was carried out in a KQ-400 kDe high power CNC ultrasonic cleaner, and the ultrasonic power was 450W, the cleaning time was 15-20 min, and the residual dirt and impurities were continued with deionized water. Then, after the physical treatment, the titanium-based body was placed in a hydroxide solution having a mass fraction of 40%, and the constant temperature was kept at a temperature of 80 ° C for 2 h, and after removal, washed with deionized water. Then, the titanium sheet after washing is completely immersed in 15% oxic acid solution, and the water bath is 95 ° C, and the acid etched is heated. It is boil for 3 h. After the cooling is removed, clean it with distilled wa...

Embodiment 3

[0039] (1) First use the linear cutter to cut the titanium plate of 300 mm × 300 mm to a titanium plate having a plurality of sizes of 50 mm × 20 mm, first using 200 mesh crude sandpaper, and then use the 800 destination fine sandpaper to polish, so silver white metal. luster. Then, 50 mm × 20 mM titanium plate was carried out in a KQ-400 kDe high power CNC ultrasonic cleaner, and the ultrasonic power was 450W, the cleaning time was 15-20 min, and the residual dirt and impurities were continued with deionized water. Then, after the physical treatment, the titanium-based body was placed in a hydroxide solution having a mass fraction of 40%, and the constant temperature was kept at a temperature of 80 ° C for 2 h, and after removal, washed with deionized water. Then, the titanium sheet after washing is completely immersed in 15% oxic acid solution, and the water bath is 95 ° C, and the acid etched is heated. It is boil for 3 h. After the cooling is removed, clean it with distilled w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com