Graphite negative electrode material and preparation method thereof

A graphite anode, graphite technology, applied in the direction of graphite, battery electrodes, structural parts, etc., can solve the problems of limiting the specific energy of lithium-ion batteries, unable to meet high-energy power sources, etc., to reduce the specific surface area, ensure stability, and ensure stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

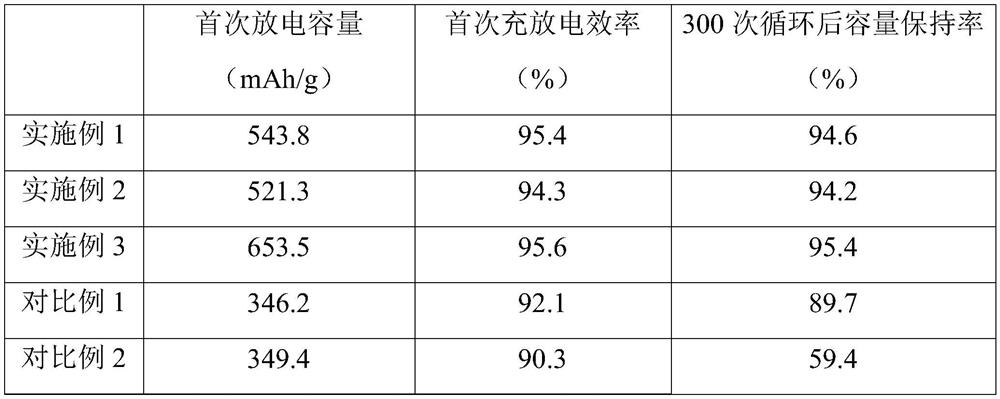

Examples

preparation example Construction

[0024] A preparation method of graphite negative electrode material, is characterized in that, comprises the steps:

[0025] S1. Prepare graphite material, resin, and nano-silicon powder. First, weigh a certain amount of nano-silicon powder and put it into an alcohol solvent, and ultrasonically disperse it. Then add resin and graphite material, and add crosslinking agent and curing agent at the same time, and keep stirring. , mixed into a homogeneous slurry;

[0026] S2. Spray-drying the homogeneously mixed slurry to obtain a graphite powder whose surface is coated with a mixture of nano-silicon and resin;

[0027] S3, then mix the obtained graphite powder and asphalt powder evenly;

[0028] S4. Under the protection of an inert gas, heat up to 1250-1400°C at a rate of 20-35°C / min, keep warm for 1-9h, cool down naturally, and sieve after cooling to obtain a high-capacity graphite negative electrode material.

[0029] Further, the resin is one of phenol-formaldehyde resin, phe...

Embodiment 1

[0039] A preparation method for a graphite negative electrode material, comprising the steps of: preparing graphite material, resin, and nano-silica powder in a ratio of 100:20:10, first weighing 100g of nano-silica powder and putting it into an alcohol solvent, and ultrasonically dispersing it, and then separately Add 200g of resin and 1000g of graphite material, add crosslinking agent and curing agent at the same time, stir continuously, and mix into a uniform slurry; spray dry the uniformly mixed slurry to obtain graphite powder coated with a mixture of nano-silicon and resin on the surface; Then mix the obtained graphite powder and asphalt powder evenly according to the ratio of 100:4; then under the protection of inert gas, heat up to 1250°C at a speed of 20°C / min, keep warm for 3h, cool down naturally, after cooling After sieving, a high-capacity graphite negative electrode material can be obtained.

Embodiment 2

[0041] A preparation method for a graphite negative electrode material, comprising the steps of: preparing graphite material, resin, and nano-silica powder in a ratio of 100:10:15, first weighing 150g of nano-silica powder and putting it into an alcohol solvent, and ultrasonically dispersing, and then separately Add 100g of resin and 1000g of graphite material, add crosslinking agent and curing agent at the same time, stir continuously, and mix into a uniform slurry; spray dry the uniformly mixed slurry to obtain graphite powder coated with a mixture of nano-silicon and resin on the surface; Then mix the obtained graphite powder and asphalt powder evenly according to the ratio of 100:10; then under the protection of inert gas, heat up to 1300°C at a speed of 25°C / min, keep the temperature for 9 hours, and cool down naturally. After sieving, a high-capacity graphite negative electrode material can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com