Take-up device

A wire take-up device and wire part technology, which is applied in the direction of transportation and packaging, thin material processing, and delivery of filamentous materials, can solve the problems of uncommon heat treatment of polyester fabrics, increase production costs, and reduce production efficiency. Effects of heat treatment efficiency, efficiency improvement, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

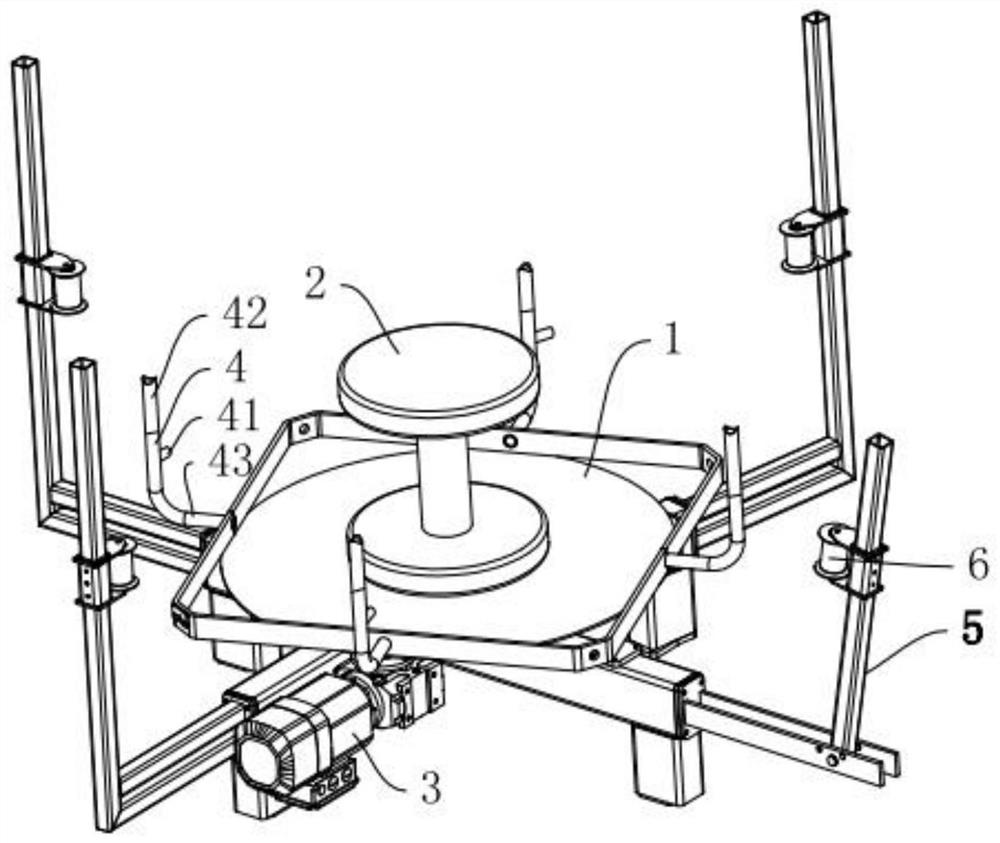

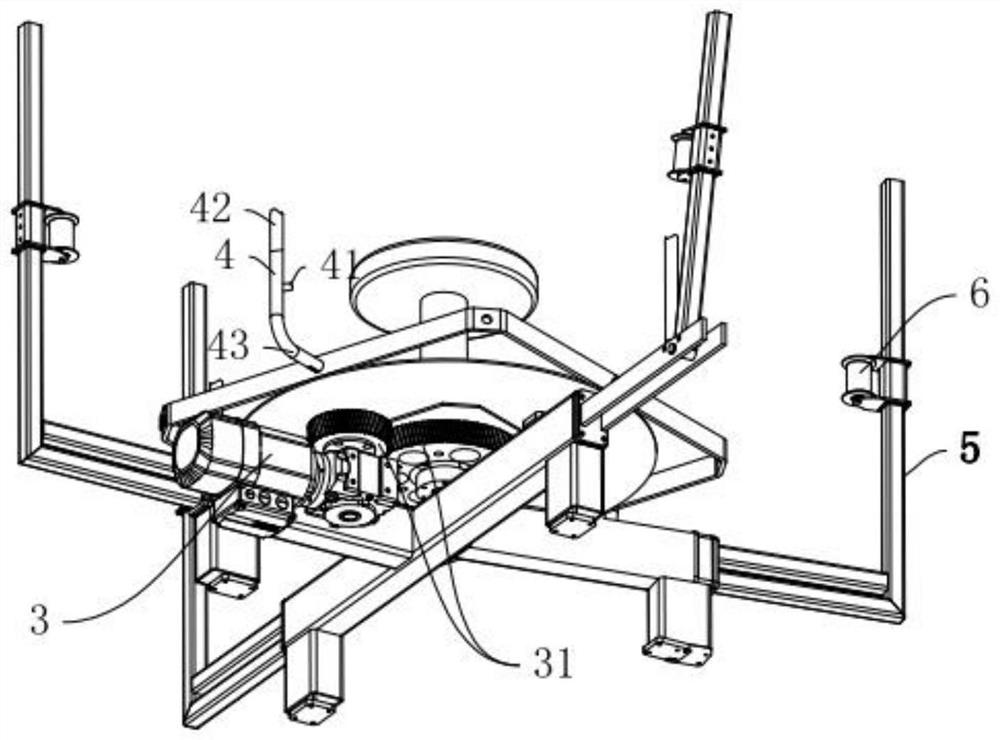

[0018] A kind of take-up device, see attached Figure 1-3 , including a take-up part, a pay-off part and a heat treatment mechanism, wherein the take-up part includes a fixed platform 1, a take-up wheel 2 is arranged on the central upper part of the platform 1, and a servo motor 3 is fixed on the lower part, and the servo motor 3 is decelerated The gear set 31 drives the take-up reel 2 .

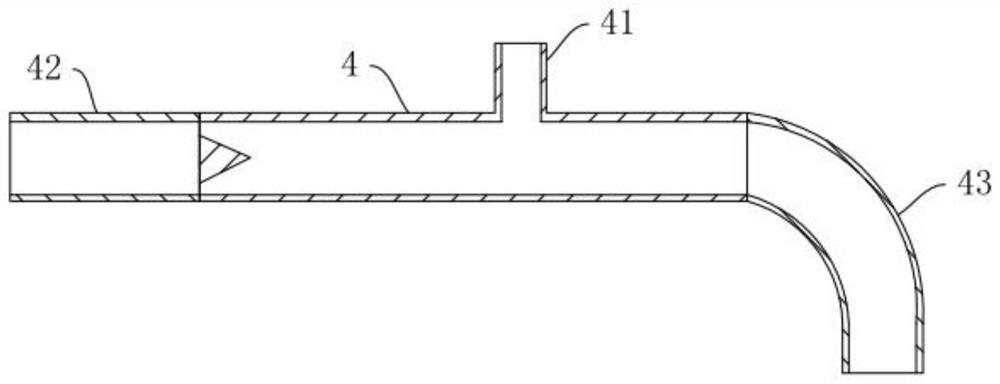

[0019] Here, in order to improve the wire take-up efficiency, the pay-off section is provided with four groups, and each group includes a bracket 5 and a pay-off wheel 6 fixed on the bracket 5 . And each pay-off reel 6 is equipped with a heat treatment mechanism, wherein the heat treatment mechanism includes a vortex tube 4, the hot air outlet end of the vortex tube 4 is connected with a heating pipe section 42, and the cold air outlet end is connected with a quenching pipe section 43. The coiled wire passes through the heating pipe section 42, the vortex tube 4 and the quenching pipe secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com