A water-cooled quenching press

A press and water-cooling technology, applied in the field of presses, can solve problems such as unsatisfactory cooling and quenching effects, affect the quality of workpieces, and reduce structural strength, and achieve the effects of improving cooling effects, quenching efficiency, and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

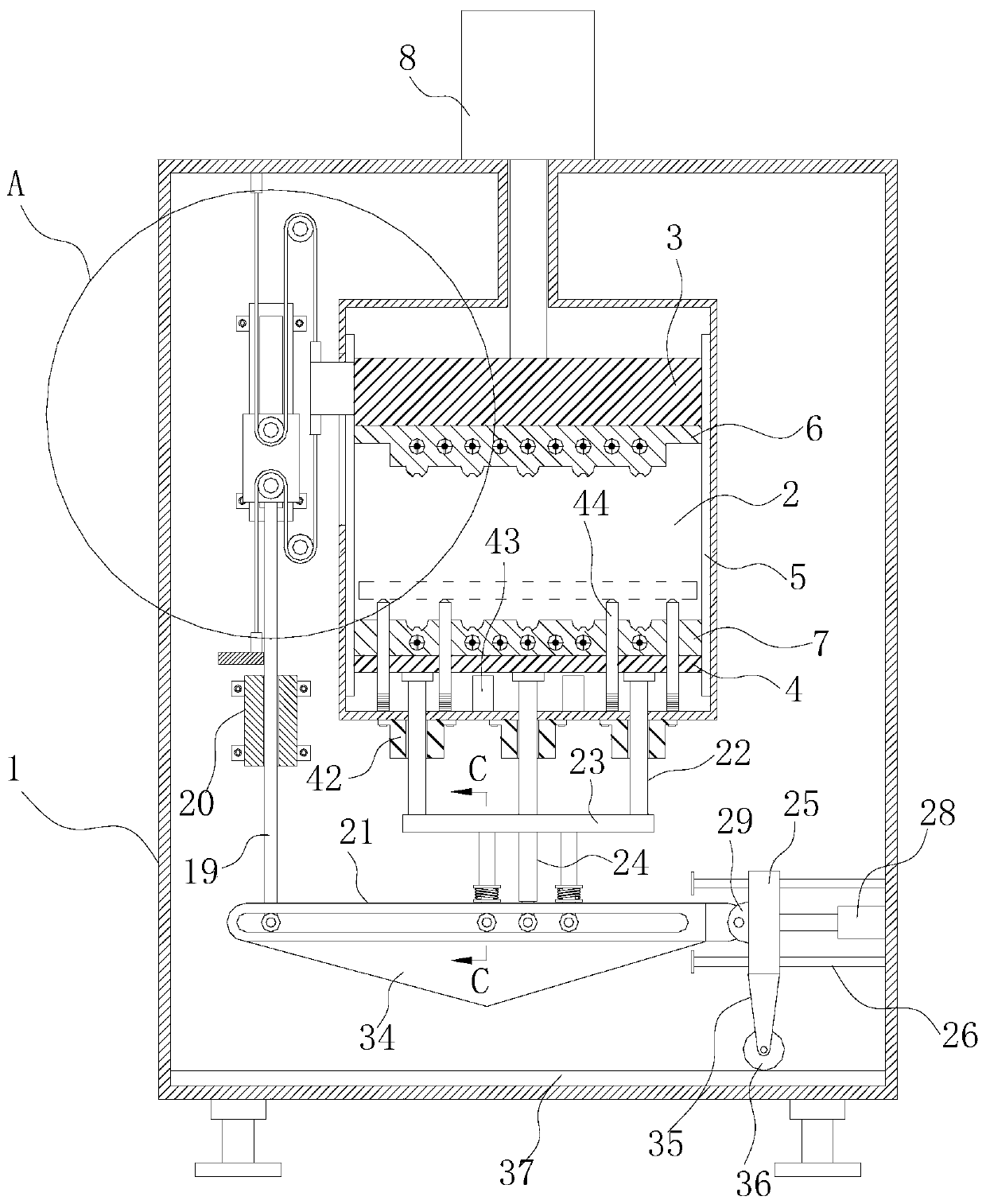

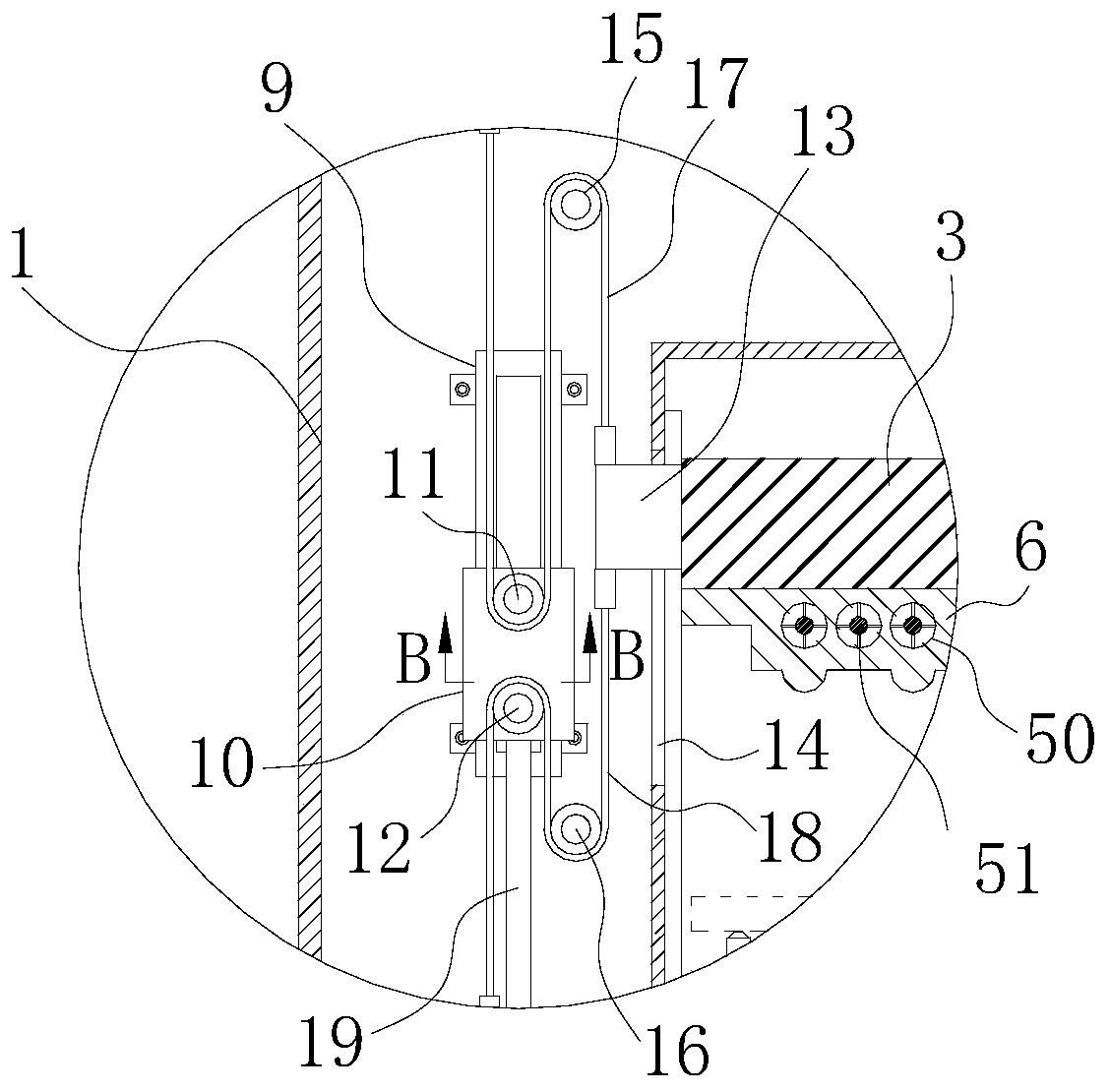

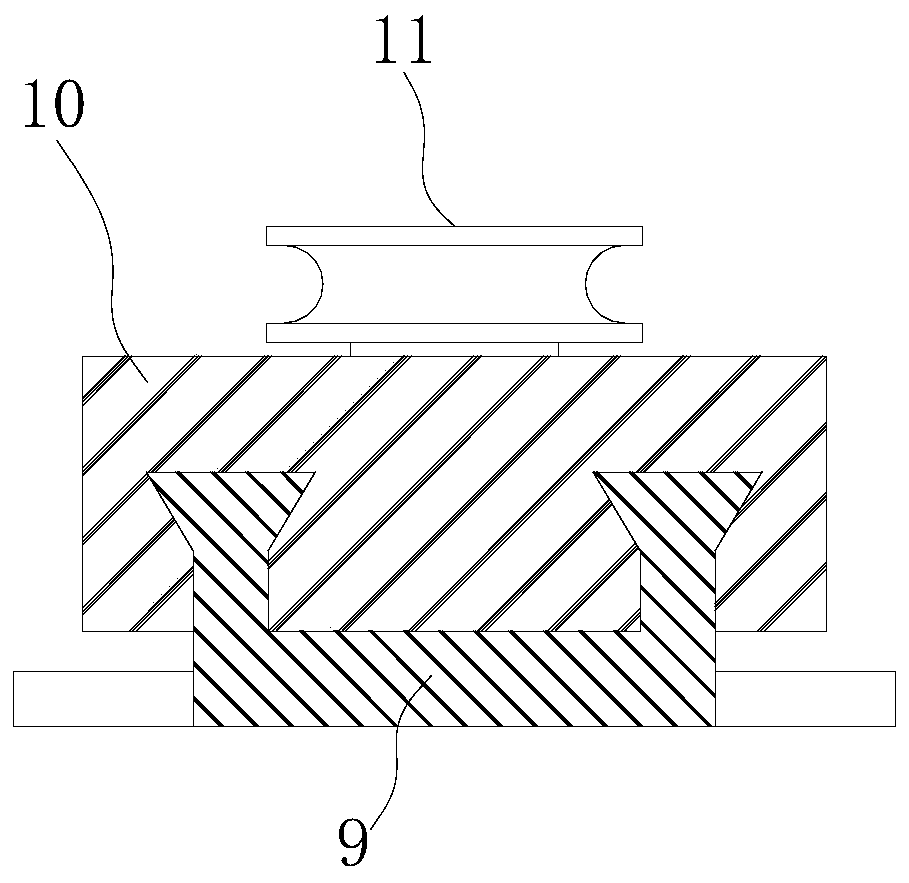

[0025] combine Figure 1-7 The press shown is improved from various aspects in order to improve the comprehensive performance of the press in view of several problems existing in the press at present. Specifically solve the problems that the existing press can only forge in one direction, the workpiece is easily damaged when ejecting the workpiece, and the cooling and quenching effect on the workpiece is poor. The improvement scheme for the three major directions can be applied to the existing pressure In the machine, it can also be applied to the existing press in any combination of two or three directions.

[0026] The press of the present invention includes a frame 1 in the shape of a square, the opening in the middle of the frame 1 constitutes a working area 2, and the working area 2 is the main area for processing workpieces in the present invention. The working area 2 is provided with an upper slider 3 and a lower slider 4 , as the name suggests, the upper slider 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com