A Casting Process of Lost Foam Dual Liquid Heat Composite Impeller

A technology of composite impeller and casting process, which is applied in the direction of manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of non-wear resistance, low casting quality, good integrity of high manganese impeller, etc., and achieve the effect of good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

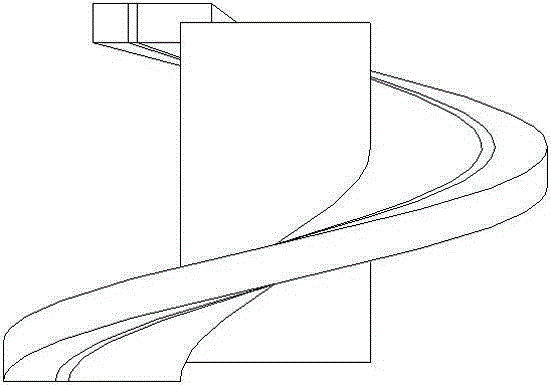

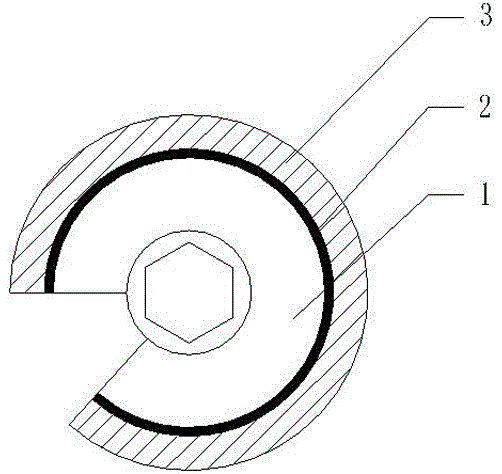

[0022] Such as figure 1 , 2, a kind of lost foam two-liquid thermal composite impeller casting process, comprising the following steps:

[0023] 1) Cut the special foam for lost foam according to the size of the impeller drawing, and glue it into the impeller foam model;

[0024] 2) Cut off the same foam on the blade of the impeller foam model according to the thickness of 1mm to cut off the vacancy of the fusion layer and the size of the high chromium alloy layer to obtain the main foam model of the impeller center;

[0025] 3) The material is a low carbon steel plate with a thickness of 1mm and a height of 38mm ( figure 2 The partition fusion layer in middle 2) is glued to the foam model of the main body in the center of the impeller;

[0026] 4) After the low-carbon steel plate is bonded to cut off the fusion layer, the thickness is 38mm and the height is 34mm ( figure 2 The high-chromium alloy layer in middle 3) is bonded to the partition fusion layer and is 2mm highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com