Robotic Force/Torque Sensor with Controlled Thermal Conduction

A technology of torque sensor and manpower, applied in force/torque/work measuring instrument, force/torque/work measuring instrument calibration/testing, instruments, etc. Ability to model signal components, the effect of increasing effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For purposes of simplicity and illustration, the invention has been described primarily by reference to exemplary embodiments thereof. In the following description, numerous specific details are set forth in order to provide a thorough understanding of the present invention. However, it will be readily apparent to one of ordinary skill in the art that the present invention may be practiced without limitation to these specific details. In this description, well-known methods and structures have not been described in detail so as not to unnecessarily obscure the present invention.

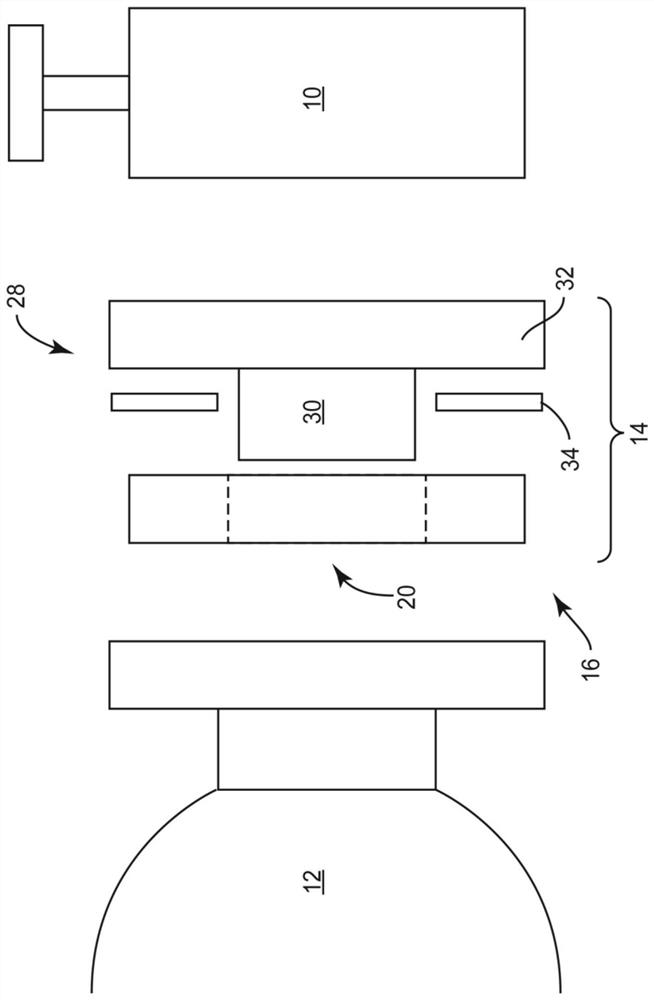

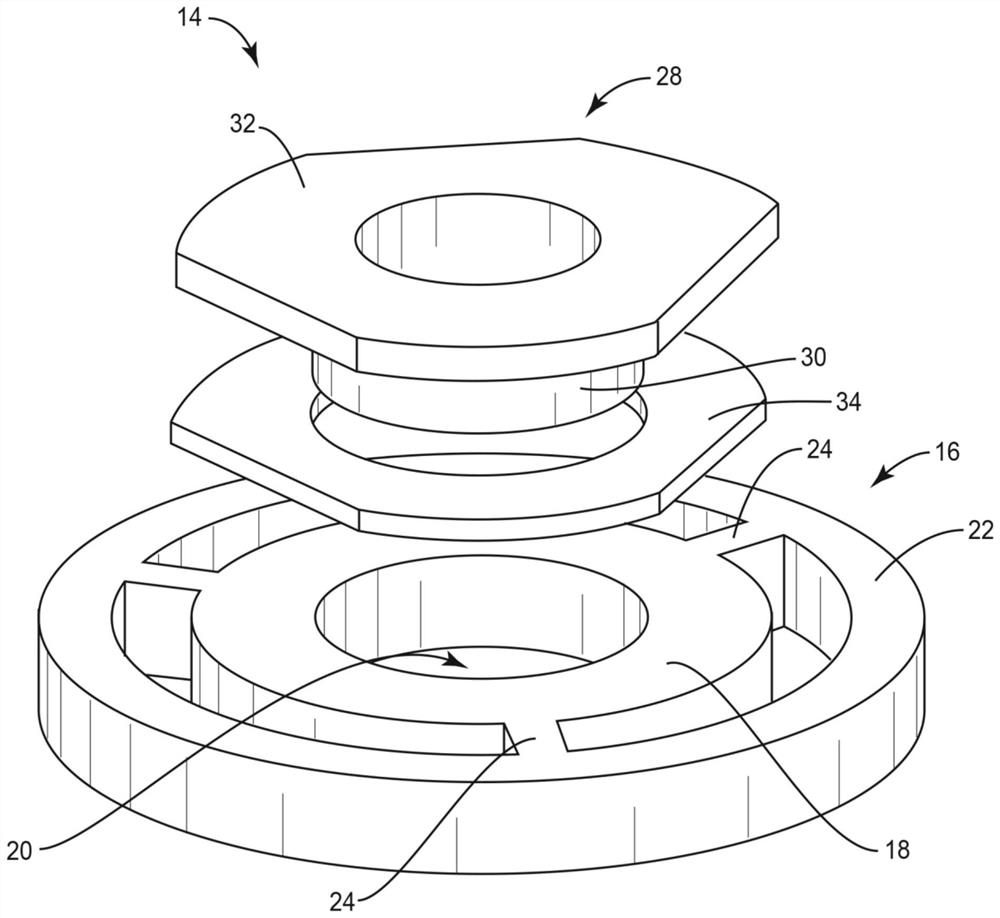

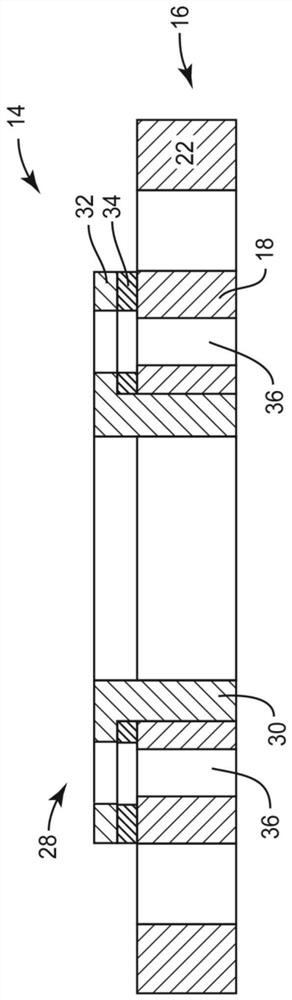

[0027] figure 1 is an exploded cross-sectional view of a typical tool 10 , such as a grinder, attached to a robotic arm 12 , such as may be deployed in a factory or other application. A robot force / torque (FT) sensor 14 is interposed between the tool 10 and the robot 12 . The FT sensor 14 measures the forces and torques between the robot 12 and the tool 10, ie when the robot 12 presses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com