Method for efficiently reducing bubbles on surface of aluminum bar and using device thereof

A technology of surface bubbles and rods, which is applied in mechanical cleaning, manufacturing tools, metal processing equipment, etc., can solve the problems of reducing the practicality and working effect of the device, reducing the functionality of the device, filtering and cleaning, etc., to improve the practicality and performance of the device. Work effect, increase pass rate, reduce quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the accompanying drawings:

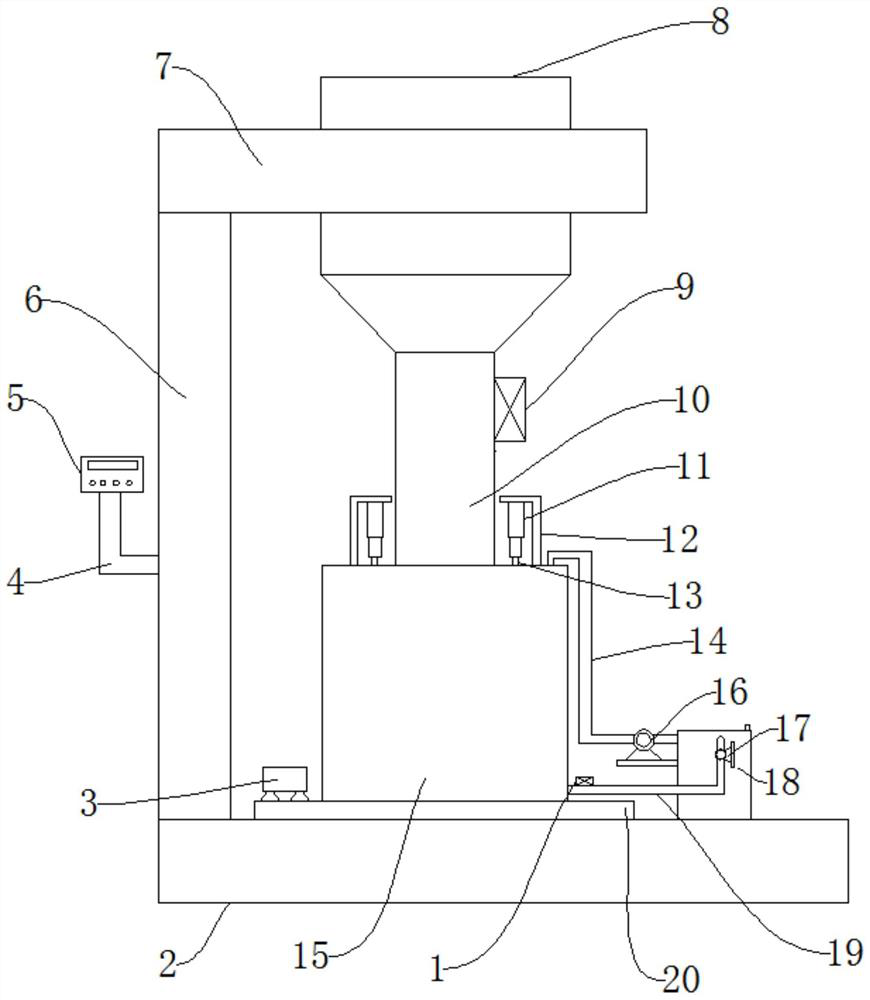

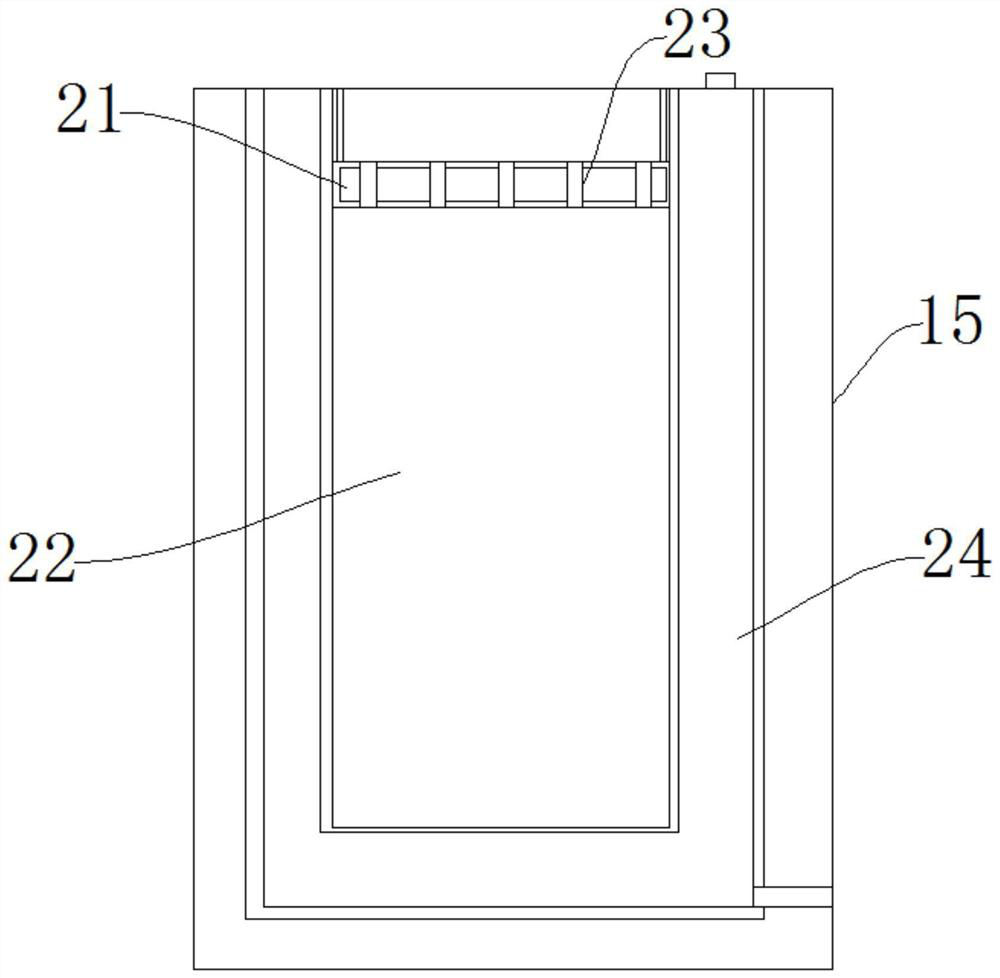

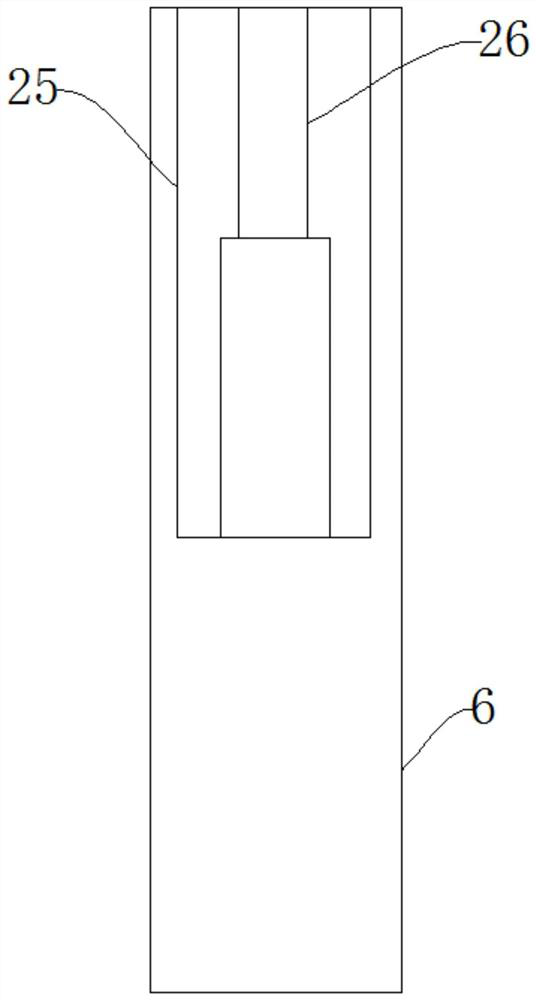

[0034] like Figure 1 - Figure 4 Shown, an efficient reduction of the aluminum rod bubble surface, comprising a base 2, a support column 6, the recess 25 and the hydraulic rod 26, the upper side of the base 2 is fixed to the support column 6, the supporting column 6 is provided with an upper end of the inner cavity 25, the cavity 25 is fixed to the hydraulic rod 26, the rod 26 of the hydraulic mount 7 is mounted to the top of the guide bracket 7 is provided with a hopper 8, the 8 the bottom end of said hopper guide tube 10 is provided with a guide, the guide hopper 8 is attached to the magnetic plate 27, provided with a filter opening 28 on the magnetic plate 27, the guide tube 10 is attached to the side wall of the flow regulating valve 9, 10 is mounted below the guide pipe 15 has a cylindrical mold, the mold drum 15 is provided with a cavity 21, the upper end of the mold ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com