Polyamide composite nanofiltration membrane based on modification of PDA/SiO2 supporting layer as well as preparation method and application of polyamide composite nanofiltration membrane

A composite nanofiltration membrane and supporting layer technology, applied in chemical instruments and methods, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. Enhanced hydrophilicity and stable retention of salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

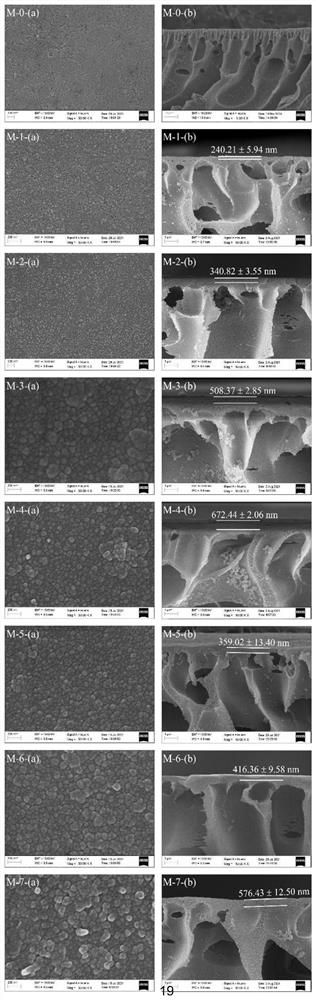

[0039] This embodiment is to prepare unmodified original PMIA substrate by non-solvent-induced phase inversion (NIPS) method, and specific process is as follows:

[0040] First, 4.5 g LiCl and 1.0 g PVP were added to 83.5 g DMAc solvent, and stirred at 25 °C until a homogeneous solution was obtained; then, 11.0 g PMIA fibers were added to the above homogeneous solution, and stirred at 85 °C Keep it in a constant temperature oil bath for about 6 hours, while stirring at 500rpm to obtain a homogeneous polymer coating solution (casting solution), cool the casting solution to 25°C for defoaming, and finally prepare the PMIA substrate by phase inversion method , recorded as M-0.

[0041] Among them, the specific preparation process of the phase inversion method is: apply the casting solution on the non-woven fabric at 25 ° C, with a thickness of 150 μm, and after staying in the air for 30 seconds, immediately transfer the new film to a temperature of 30 ° C. Phase inversion was pe...

Embodiment 2

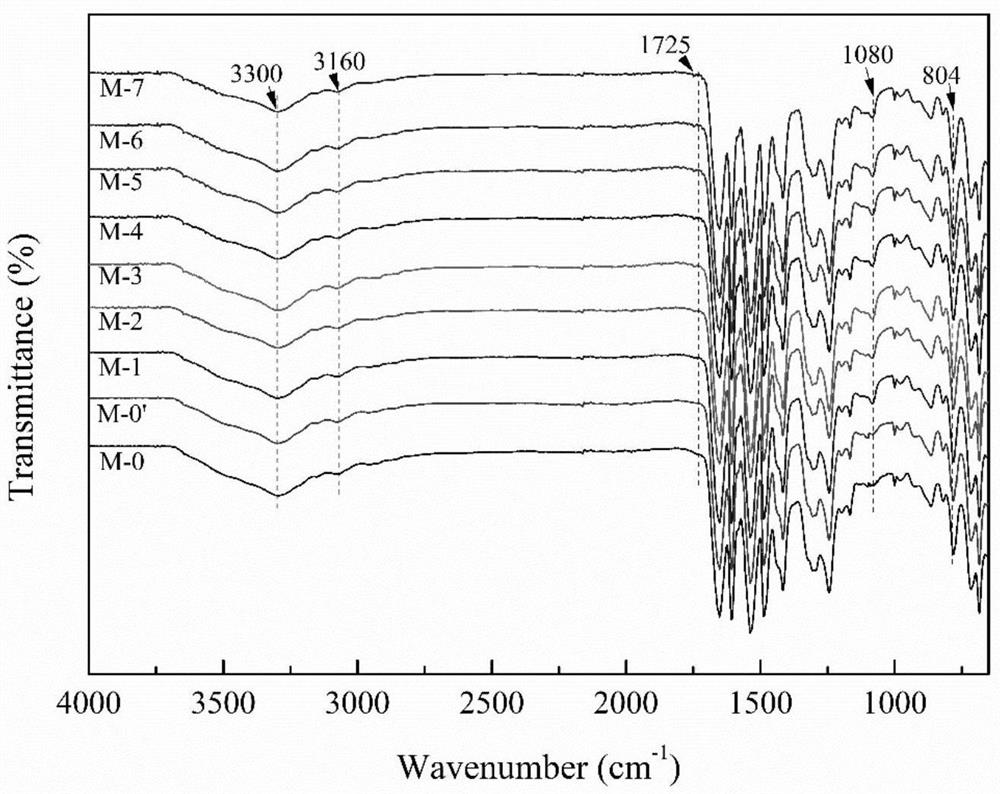

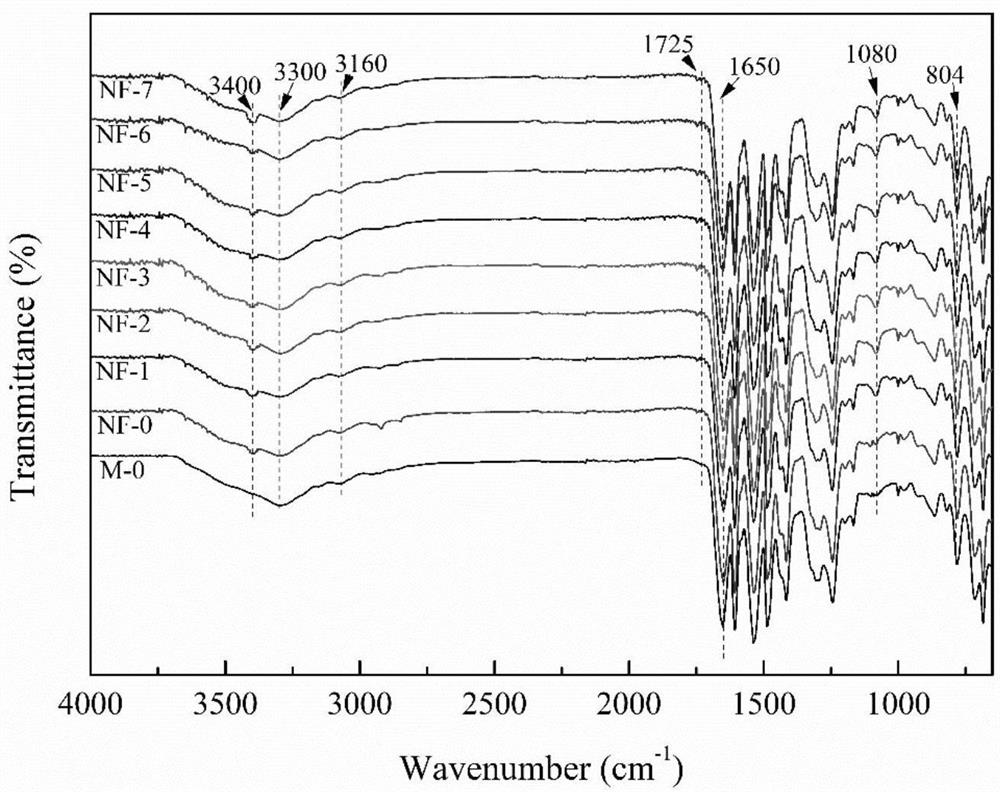

[0043] This embodiment is to prepare the PDA / SiO with the PMIA substrate M-0 that embodiment 1 makes 2 The PMIA base film of the support layer, the specific process is as follows:

[0044] First, 20mg SiO 2 (average particle size 20nm) was dissolved in 200mL Tris-HCl buffer solution (10mM, pH=8.5), stirred at 25°C for 5 minutes, then ultrasonically stirred for 30 minutes, and then stirred again for 1 hour. Next, 400mgPDA was added to the homogeneously dispersed SiO 2 solution, and then stirred at 25 °C in the dark for 5 min to obtain the PDA / SiO 2 Mixture. The PMIA substrate was fixed in a self-made airtight container, and then the PDA / SiO 2 The mixture was poured into a closed container and coated on the surface of the PMIA substrate, and the container was shaken at a speed of 130r / min on the oscillator for 20min. Finally, the film was soaked in deionized water for further use, and the obtained film product was marked for M-1.

Embodiment 3

[0046] This embodiment is also prepared with PDA / SiO with the PMIA substrate M-0 that embodiment 1 makes 2 The PMIA base film of support layer, preparation method is basically the same as embodiment 2, specifically as follows:

[0047] First, 20mg SiO 2 (average particle size 30nm) was dissolved in 200mL Tris-HCl buffer solution (10mM, pH=8.5), stirred at 800rpm at 25°C for 8 minutes, then ultrasonically stirred for 40 minutes, and then stirred again for 1 hour. Next, 400 mg PDA was added to the homogeneously dispersed SiO 2 solution, and then stirred at 30 °C in the dark for 5 min to obtain PDA / SiO 2 Mixture. The PMIA substrate was fixed in a self-made airtight container, and then the PDA / SiO 2 The mixture was poured into a closed container and coated on the surface of the PMIA substrate, and the container was shaken at a speed of 100r / min on the oscillator for 40min. Finally, the film was soaked in deionized water for further use, and the obtained film product was marked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com