A method for improving the carbonization yield of viscose-based carbon felt

A viscose-based, high-temperature carbonization technology, which is applied in the fields of fiber chemical characteristics, rayon chemical post-treatment, textiles and papermaking, etc., can solve problems such as organoboron compounds that have not been reported, shorten pre-oxidation time, and increase carbonization yield , The effect of carbonization yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

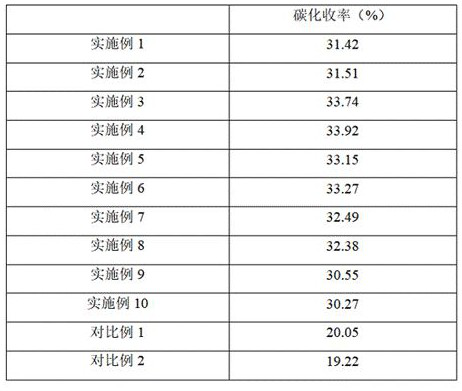

Examples

Embodiment 1

[0025] A method for improving the carbonization yield of viscose-based carbon felt, comprising the following steps:

[0026] Step (1) Soak the viscose fiber in the organoboron catalyst for 10 minutes, dehydrate it, and wash it with 40°C pure water for 15 minutes. The preparation method of the organoboron catalyst is as follows: 3 parts of boric acid tris Dissolve isopropyl ester in 30 parts of absolute ethanol, stir evenly, add 1 part of cyanuric chloride, after fully stirring, add 1 part of melamine borate, fully stir and mix evenly, and finally dissolve in 100 parts of absolute ethanol to obtain organoboron Catalysts;

[0027] Step (2) Dry in an oven at 105°C for 120 minutes;

[0028] Step (3) Pre-oxidation: pre-oxidize the dried fibers in a pre-oxidation furnace, pre-oxidize into two temperature zones, the first temperature zone temperature is 200 ° C, the second temperature zone temperature is 220 ° C, pre-oxidation Time: 20 minutes in the first temperature zone, 20 minu...

Embodiment 2

[0031] A method for improving the carbonization yield of viscose-based carbon felt, comprising the following steps:

[0032] Step (1) Soak viscose fiber in organoboron catalyst, use ultrasonic prepreg process, ultrasonic power 80W, dehydrate after ultrasonic 3min at room temperature, wash with 40℃ pure water for 15min, among them, the preparation of organoboron catalyst The method is: in a nitrogen atmosphere protected stirring tank, dissolve 3 parts of triisopropyl borate in 30 parts of absolute ethanol, stir evenly and add 1 part of cyanuric chloride, after fully stirring, add 1 part of boric acid melamine, fully stir and mix homogeneous, then dissolved in 100 parts of absolute ethanol to obtain organoboron catalysts;

[0033] Step (2) Dry in an oven at 105°C for 120 minutes;

[0034] Step (3) Pre-oxidation: pre-oxidize the dried fibers in a pre-oxidation furnace, pre-oxidize into two temperature zones, the first temperature zone temperature is 200 ° C, the second temperatu...

Embodiment 3

[0037] A method for improving the carbonization yield of viscose-based carbon felt, comprising the following steps:

[0038] Step (1) Soak the viscose fiber in an organoboron catalyst for 20 minutes, dehydrate it, and wash it with 50°C pure water for 15 minutes. The preparation method of the organoboron catalyst is as follows: 5 parts of boric acid tris Dissolve isopropyl ester in 30 parts of absolute ethanol, stir evenly, add 2 parts of cyanuric chloride, after fully stirring, add 2 parts of melamine borate, fully stir and mix evenly, and finally dissolve in 100 parts of absolute ethanol to obtain organoboron Catalysts;

[0039] Step (2) drying in an air circulation furnace for 120 minutes;

[0040] Step (3) Pre-oxidation: pre-oxidize the dried fibers in a pre-oxidation furnace, pre-oxidize into two temperature zones, the first temperature zone temperature is 210°C, the second temperature zone temperature is 230°C, pre-oxidation Time: 25 minutes in the first temperature zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com