Preparation method of perfluoropolyether siloxane product and application of product in super-hydrophobic anti-fingerprint coating

A perfluoropolyether siloxane and product technology, applied in polyether coatings, coatings, etc., can solve problems such as high cost and harsh environment, and achieve the effects of reducing production costs, good adhesion, and excellent antifouling performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

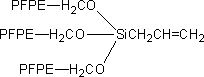

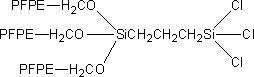

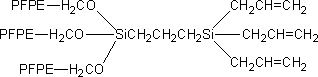

[0070] The embodiment of the present invention provides a preparation method of perfluoropolyether siloxane compound, comprising the following steps:

[0071] (1) in N 2 Under protected conditions, add 20g allyl bromide, 16.3-20.7g cuprous chloride and 20-31g organic base to the reactor, add 29g trichlorosilane dropwise at room temperature, and reflux the reaction for 6 hours until the system has no reflux state; After the completion, the insoluble matter was removed by filtration, and the unreacted trichlorosilane and organic base were extracted with the extractant tetrahydrofuran, the non-extractant layer was collected, and the residual tetrahydrofuran was distilled off under reduced pressure to obtain the intermediate product I (allyltrichlorosilane).

[0072] (2) in N 2 Under the condition of protection, add 50g perfluoropolyether alcohol (molecular weight: 1000~2000), 1.3~2.9g intermediate product I, 3.6~6.7g potassium tert-butoxide, 110mL tert-butanol into the reactor, ...

Embodiment 5

[0094] The preparation method of a perfluoropolyether siloxane compound is basically the same as that in Example 1, the difference is that: the reaction temperature in the step (2) is 50°C; the reaction temperature in the step (3) is 90°C °C; the reaction temperature in step (5) is 90 °C; the reaction temperature in step (6) is 80 °C.

Embodiment 6

[0096] The preparation method of a perfluoropolyether siloxane compound is basically the same as in Example 1, except that the reaction temperature in step (2) is 60 °C; the reaction temperature in step (3) is 120 °C °C; the reaction temperature in step (5) is 120 °C; the reaction temperature in step (6) is 90 °C.

[0097] 2. Preparation of superhydrophobic anti-fingerprint coating

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com