Stator and servo motor comprising same

A technology of servo motor and stator, applied in the field of servo drive system, can solve the problem of high material cost, achieve the effect of small effective air gap, less amount of magnetic steel, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

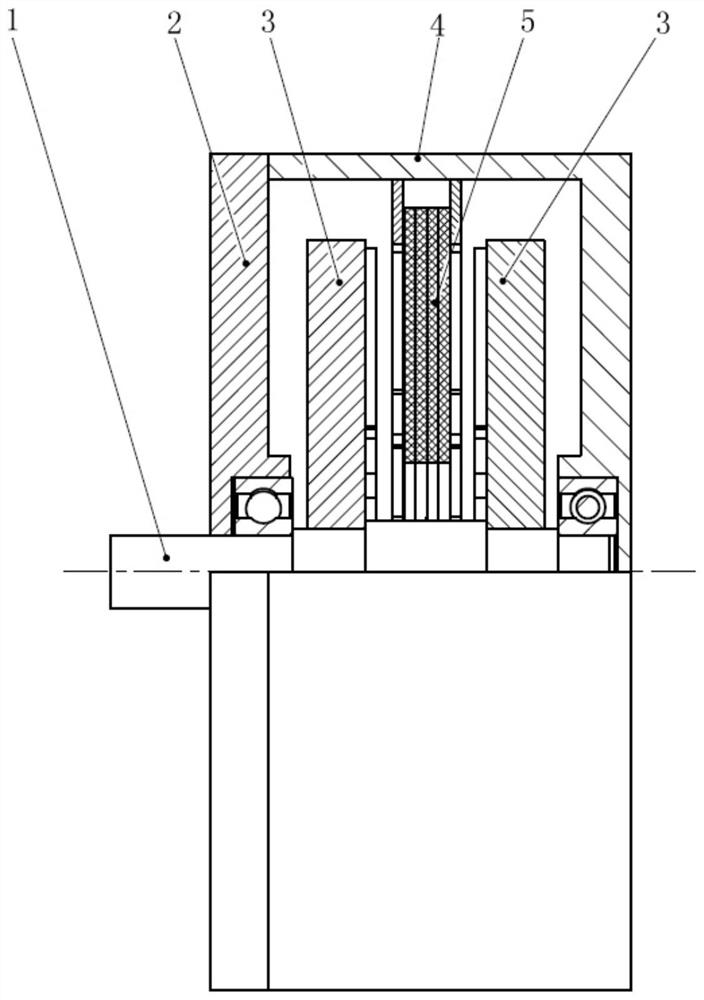

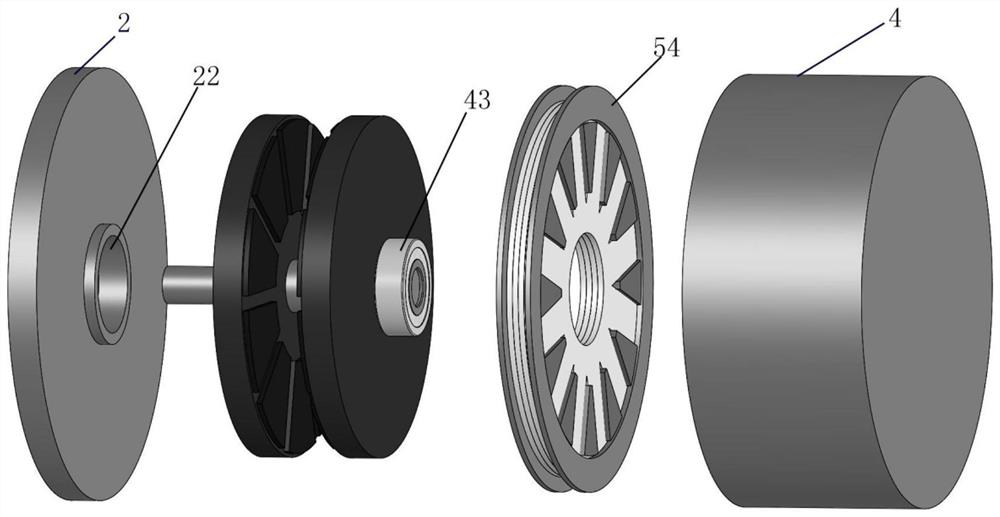

[0042] figure 1 It is a schematic diagram of a single-stator dual-rotor servo motor according to an exemplary embodiment of the present invention; Figure 2A with Figure 2B for figure 1 An exploded view of the single-stator dual-rotor servo motor shown in ; image 3 A cross-sectional view is presented for a single-stator dual-rotor servo motor cut along a radial direction according to an exemplary embodiment of the present invention.

[0043] like figure 1 , 3 As shown in , the single-stator double-rotor servo motor according to the exemplary embodiment of the present invention includes a motor shaft 1 , a motor end cover 2 , two rotors 3 , a casing 4 , and a stator 5 .

[0044] The motor shaft 1 has a stepped cylindrical shape as a whole, that is, the motor shaft 1 is integrally formed by a plurality of cylinders with different diameters. Specifically, the motor shaft 1 has a first section 11 with the largest diameter in the middle of the axial direction. Both sides of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com