High-temperature-resistant and high-voltage-resistant lithium ion battery electrolyte, and preparation method and application thereof

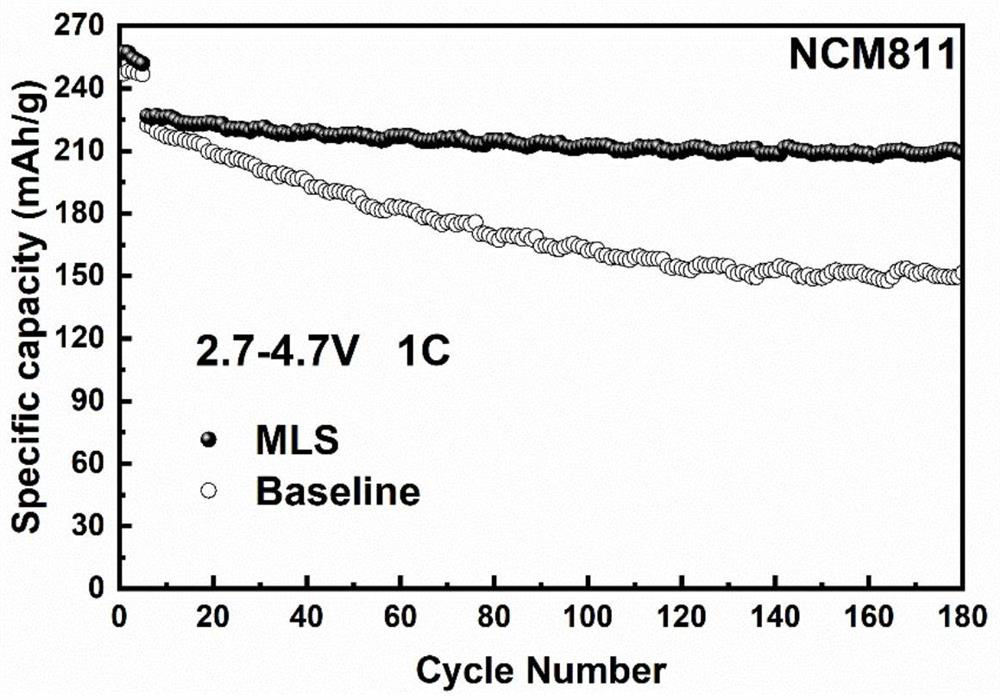

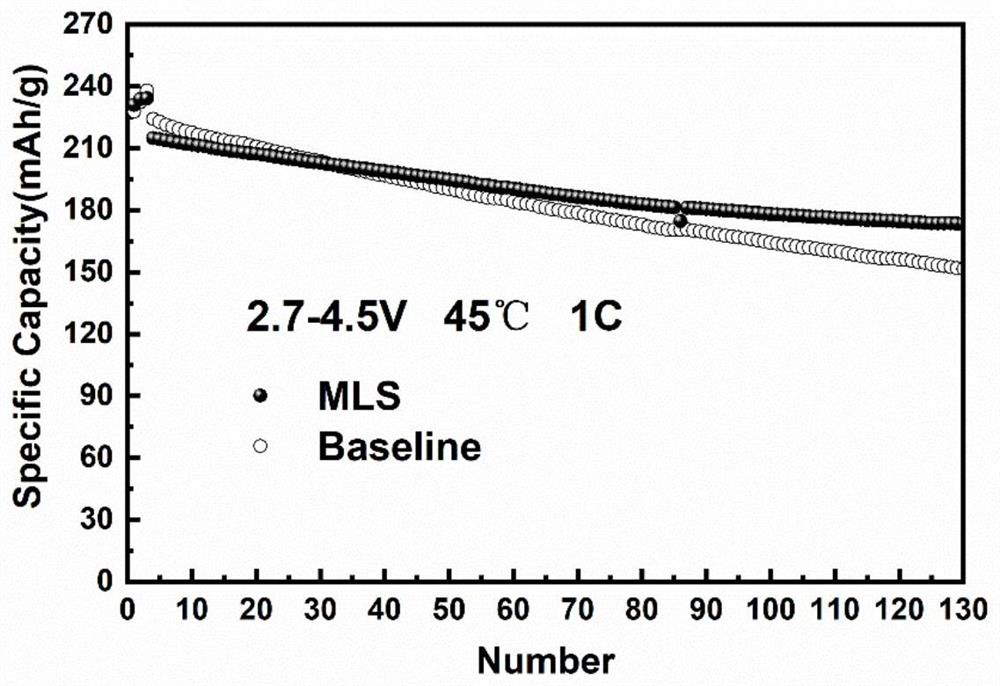

A lithium-ion battery and electrolyte technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of serious side reactions at the interface of the positive electrode electrolyte, serious electrolyte decomposition, etc., to optimize the composition and properties, and suppress irreversibility. The effect of transforming and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

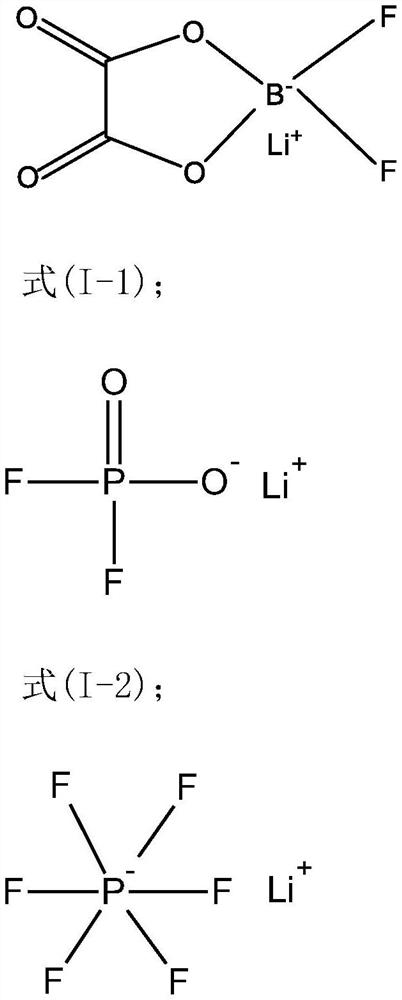

[0043] Mix the linear carbonate solvent and the cyclic carbonate solvent at a volume ratio of 1:1 in an inert gas-protected glove box, and then add Molecular sieve dewatering agent, let it stand for 2 days, then add lithium difluorooxalate borate (I-1), control the concentration of lithium difluorooxalate borate to 0.5mol / L, stir until it is clear and transparent, then add lithium difluorophosphate (I-1) 2), the concentration is 0.1mol / L, finally add 0.1mol / L lithium hexafluorophosphate (I-3) and stir until clear and transparent, and the finished product can be obtained after mixing evenly. The water content in the glove box is less than 0.1ppm, and the oxygen content is less than 0.1ppm. The model of molecular sieve water remover is Alfa L05335-250g.

[0044] The difference between the preparation methods of Inventive Examples 2-15 and Comparative Example and Example 1 lies in the type and concentration of the electrolyte salt used. To simplify the description, see Table 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com