Preparation method of anti-mosquito polyester yarn, anti-mosquito fabric and clothes

A polyester yarn and anti-mosquito technology, applied in yarn, rayon manufacturing, textile, etc., can solve the problems of poor washability, low fiber bonding, and poor anti-mosquito durability, and achieve more durable anti-mosquito and high bonding , Anti-mosquito lasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

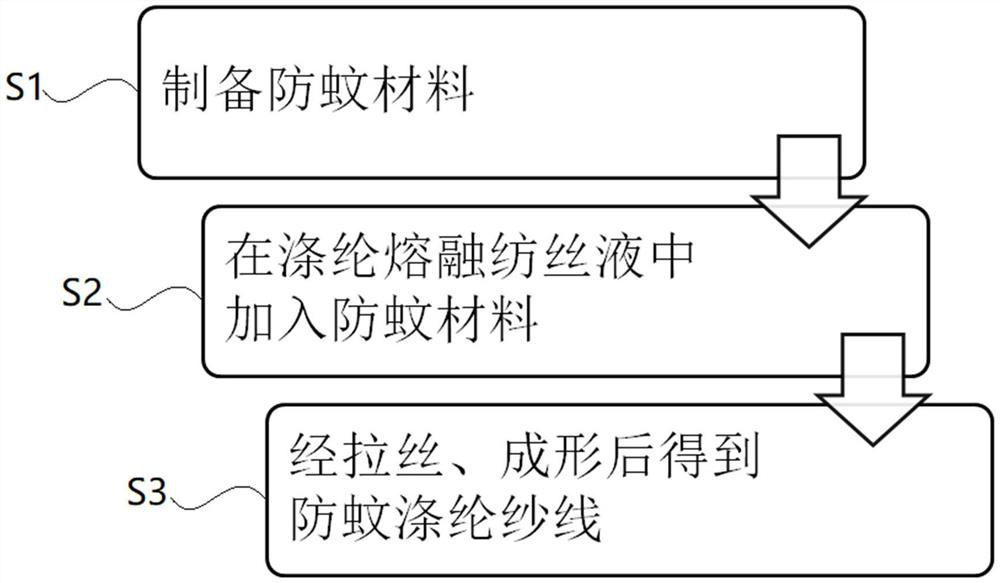

[0024] Such as figure 1 As shown, the present embodiment provides a preparation method of anti-mosquito polyester yarn, comprising the following steps:

[0025] Step S1. Prepare mosquito-proof material;

[0026] Step S2. Adding anti-mosquito material to polyester melt spinning solution;

[0027] Step S3. After drawing and forming, the anti-mosquito polyester yarn is obtained.

[0028] Wherein, the preparation process of the anti-mosquito material described in step S1 includes:

[0029] Step S11 wrapping 3.6 parts by weight of the anti-mosquito material in microcapsules with a maximum heat-resistant temperature of 280°C;

[0030] In step S12, the treated microcapsules are put into a granulator for blending, extruding, and dicing to prepare the mosquito repellent material.

[0031] In step S12, the temperature during blending in the granulator does not exceed 280°C.

[0032] In this embodiment, the anti-mosquito material is specifically made of ethyl butylacetamidopropionat...

Embodiment 2

[0036] This embodiment provides another method for preparing mosquito-resistant polyester yarn, which includes the following steps: Step S1. Prepare mosquito-proof material; Step S2. Add mosquito-proof material to polyester melt spinning solution; Step S3. After drawing, After forming, the anti-mosquito polyester yarn is obtained.

[0037] Wherein, the preparation process of the anti-mosquito material in the step S1 includes: step S11 wrapping 0.7 parts by weight of the anti-mosquito material in microcapsules with a maximum heat-resistant temperature of 280°C; step S12 putting the treated microcapsules into The anti-mosquito material is prepared by blending, extruding and pelletizing in the granulator.

[0038] In step S12, the temperature during blending in the granulator does not exceed 280°C.

[0039] The difference between this embodiment and the first embodiment is that 0.7 parts by weight of the anti-mosquito material is selected to wrap the microcapsules, and the cost ...

Embodiment 3

[0043] This embodiment provides another preparation method of mosquito-resistant polyester yarn, which is different from Embodiment 1 and Embodiment 2 in that permethrin is selected as the main mosquito-resistant material; it includes the following steps: Step S1. Preparation Anti-mosquito material; Step S2. Add anti-mosquito material to polyester melt spinning solution; Step S3. Obtain anti-mosquito polyester yarn after drawing and forming.

[0044] Wherein, the preparation process of the anti-mosquito material in the step S1 includes: step S11 wrapping 3.6 parts by weight of the anti-mosquito material in microcapsules with a maximum heat-resistant temperature of 280°C; step S12 putting the treated microcapsules into The anti-mosquito material is prepared by blending, extruding and pelletizing in the granulator.

[0045]In step S12, the temperature during blending in the granulator does not exceed 280°C.

[0046] In this embodiment, the anti-mosquito material is specifically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com