Preparation method of rubber floor containing colored rubber particles and rubber floor

A rubber floor and particle technology, which is applied in the rubber field, can solve the problems of easy scratching of soles, decreased soil resistance on the floor surface, cracks, etc., and achieves the effect of simplifying the crushing and screening process, improving the product qualification rate and saving production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Mixed rubber formula: (by weight)

[0071] SBR 1502 60 high styrene 10 Chlorinated polyethylene 35 Zinc oxide 5 stearic acid 4 Anti-1076 2 Microcrystalline Wax 1 polyethylene wax 1.5 Titanium dioxide 930 3 Aluminum hydroxide 40 Zinc borate 20 Shanxi clay 70 Silica 30 Silicon 69 2 polyethylene glycol 1.5 accelerator DM 2 Accelerator CZ 1.5 Accelerator EZ 1.2 S 4.5

[0072] Based on 100 parts by weight of the base rubber, the consumption of flower glue particles is 5 parts by weight;

[0073] Preparation methods include:

[0074] (1) adding flower gum granules during mixing to obtain a mixed rubber containing flower gum particles;

[0075] (2) The mixed rubber sheeting containing flower gum particles is cut into rubber floor semi-finished film;

[0076] The size of the film is 515*515mm; the thickness is 7mm;

[0077] (3) The rubber floor sem...

Embodiment 2

[0086] Mixed rubber formula is the same as embodiment 1.

[0087] Based on 100 parts by weight of the base rubber, the consumption of flower glue particles is 10 parts by weight;

[0088] Preparation methods include:

[0089] (1) adding flower gum granules during mixing to obtain a mixed rubber containing flower gum particles;

[0090] (2) The mixed rubber sheeting containing flower gum particles is cut into rubber floor semi-finished film;

[0091] The size of the film is 615*615*mm; the thickness is 10mm;

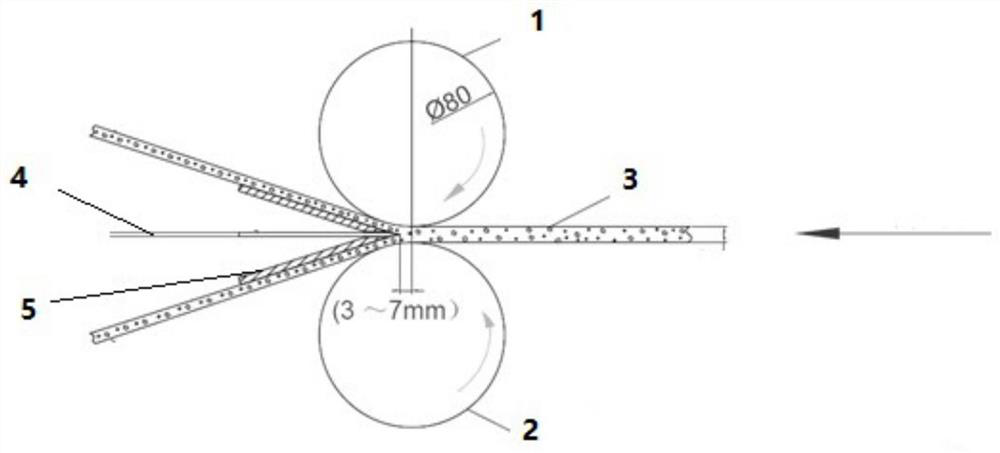

[0092] (3) The rubber floor semi-finished film is placed on the opening machine, and the film is opened along the thickness direction of the semi-finished film; one semi-finished film is divided into two pieces;

[0093] The feed speed of the slicer blade is 10m / min.

[0094] The wedge-shaped minimum gap between the blade and the upper and lower pressure rollers deviates backward by 7 mm, which is used as the initial position for cutting and slicing.

[0095] (4) The...

Embodiment 3

[0101] Based on 100 parts by weight of the base rubber, the consumption of flower glue particles is 10 parts by weight;

[0102] Preparation methods include:

[0103] (1) adding flower gum granules during mixing to obtain a mixed rubber containing flower gum particles;

[0104] (2) The mixed rubber sheeting containing flower gum particles is cut into rubber floor semi-finished film;

[0105] The size of the film is 1025*1025mm; the thickness is 9mm;

[0106] (3) The rubber floor semi-finished film is placed on the opening machine, and the film is opened along the thickness direction of the semi-finished film; one semi-finished film is divided into two pieces;

[0107] The feed speed of the slicer blade is 8m / min.

[0108] The wedge-shaped minimum gap between the blade and the upper and lower pressure rollers deviates backward by 5 mm, which is used as the initial position for cutting and slicing.

[0109] (4) The semi-finished film after filming is vulcanized;

[0110] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com